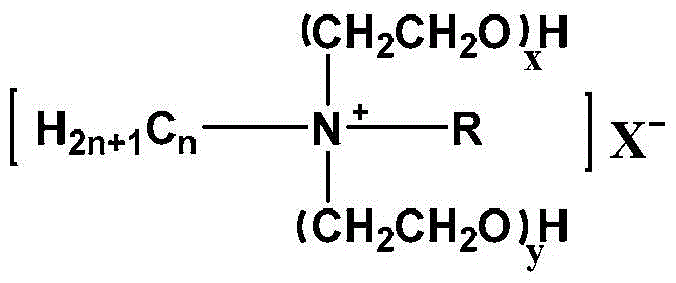

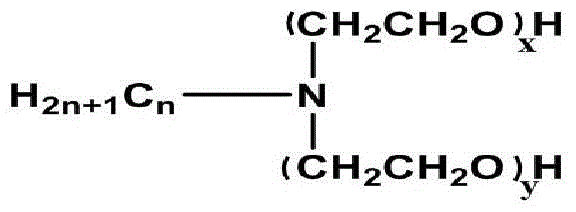

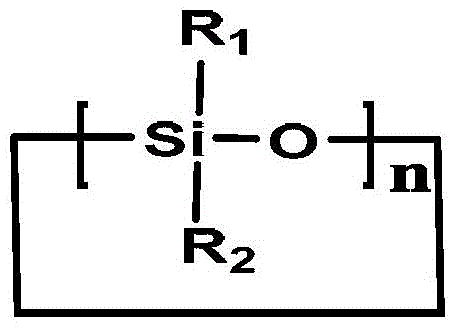

Method for preparing high molecular weight polysiloxane miniemulsion with long-chain alkyl polyoxyethylene quaternary ammonium salt emulsifier

A technology of long-chain alkyl polyoxyethylene quaternary ammonium salt and polysiloxane is applied in the field of preparing high molecular weight polysiloxane miniemulsion, which can solve the problems of increased emulsion stability, increased interface film thickness, poor emulsion stability and the like , to achieve the effect of less emulsifier dosage, uniform distribution and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of octadecyl polyoxyethylene (the number of oxyethylene groups (x+y) in the structure is 10) benzyl ammonium bromide:

[0045] (a) Quaternization of fatty amine polyoxyethylene: Dissolve octadecylamine polyoxyethylene ether in ethanol (the mass of octadecylamine polyoxyethylene ether and ethanol is The ratio is 1:0.5), the temperature is raised to 70°C, and the benzyl chloride solution is added dropwise at a rate of 20 drops / min (the solvent is ethanol, the mass ratio of benzyl chloride to ethanol is 1:1), and the reflux reaction is continued for 15 hours. The whole process Carried out in N2 atmosphere to obtain a reaction product; wherein, the molar ratio of benzyl chloride to stearylamine polyoxyethylene ether is 1.2:1;

[0046] (b) Purification of long-chain alkyl polyoxyethylene quaternary ammonium salt: remove the solvent in the reaction product, dry, dissolve the dried product in ethyl acetate (solvent A), and recrystallize (60°C), Redissolve in petro...

Embodiment 2

[0048] Preparation of octadecyl polyoxyethylene (the number of oxyethylene groups (x+y) in the structure is 15) benzyl ammonium chloride:

[0049] (a) Quaternization of fatty amine polyoxyethylene: Dissolve octadecylamine polyoxyethylene ether in isopropanol under stirring (150r / min) The mass ratio of propanol is 1:0.6), the temperature is raised to 82°C, and the benzyl chloride solution is added dropwise at a rate of 25 drops / min (the solvent is isopropanol, and the mass ratio of benzyl chloride to isopropanol is 0.7:1 ), the reflux reaction was continued for 26 hours, the whole process was carried out in N2 atmosphere, and the reaction product was obtained; the molar ratio of benzyl chloride to octadecylamine polyoxyethylene ether was 1.3:1;

[0050] (b) Purification of long-chain alkyl polyoxyethylene quaternary ammonium salt: remove the solvent in the reaction product, dry, dissolve the dried product in ethyl acetate (solvent A), and recrystallize (60°C), Redissolve in pe...

Embodiment 3

[0052] Preparation of cetyl polyoxyethylene (the number of oxyethylene groups (x+y) in the structure is 10) benzyl ammonium chloride:

[0053] (a) Quaternization of aliphatic amine polyoxyethylene: Dissolve hexadecylamine polyoxyethylene ether in n-propanol under stirring (350r / min) (hexadecylamine polyoxyethylene ether and n-propanol The mass ratio of propanol is 1:0.8), the temperature is raised to 100°C, and the benzyl chloride solution is added dropwise at a rate of 22 drops / min (the solvent is methanol, and the mass ratio of benzyl chloride to methanol is 0.5:1), and the reflux is continued The reaction was carried out for 10 hours, and the whole process was carried out in an N2 atmosphere to obtain a reaction product; wherein the molar ratio of benzyl chloride to hexadecylamine polyoxyethylene ether was 1.1:1;

[0054] (b) Purification of long-chain alkyl polyoxyethylene quaternary ammonium salt: remove the solvent in the reaction product, dry it, dissolve the dried prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com