Mold capable of protecting outer wall of molded blank material

A technology for forming blanks and molds, which is applied in the field of molds that can protect the outer wall of the forming blanks, and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

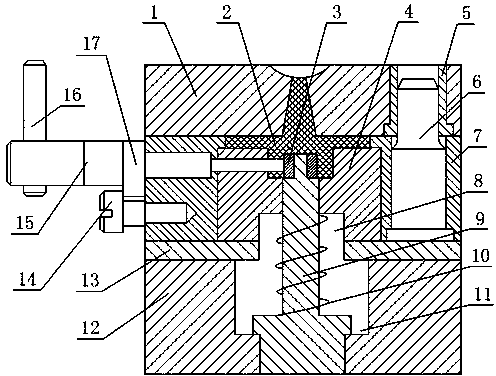

[0012] Such as figure 1 As shown, a mold capable of protecting the outer wall of a forming blank includes a base 12, a fixed mold base 1 is arranged above the base 12, a movable template 7 is arranged between the fixed mold base 1 and the base 12, and the top of the movable template 7 In contact with the bottom of the fixed mold base 1, a support plate 13 is provided between the movable template 7 and the base 12, the top of the support plate 13 contacts the bottom of the movable template 7, and the bottom of the support plate 13 contacts the top of the base 12 , the movable template 7 is provided with a through hole, the through hole is provided with a punch 4, the bottom of the punch 4 is in contact with the top of the support plate 13, the top of the punch 4 is concave to form a groove 1, and the punch 4 is set There is a push rod 9, and one end of the push rod 9 is arranged in the base 12, and the other end passes through the support plate 13 and the punch 4 and is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com