Metal wetting agent and preparation method of composite material

A composite and wetting agent technology, applied in the coating and other directions, can solve the problems of difficulty in reaching the ideal level, unfavorable processing, limited bonding strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

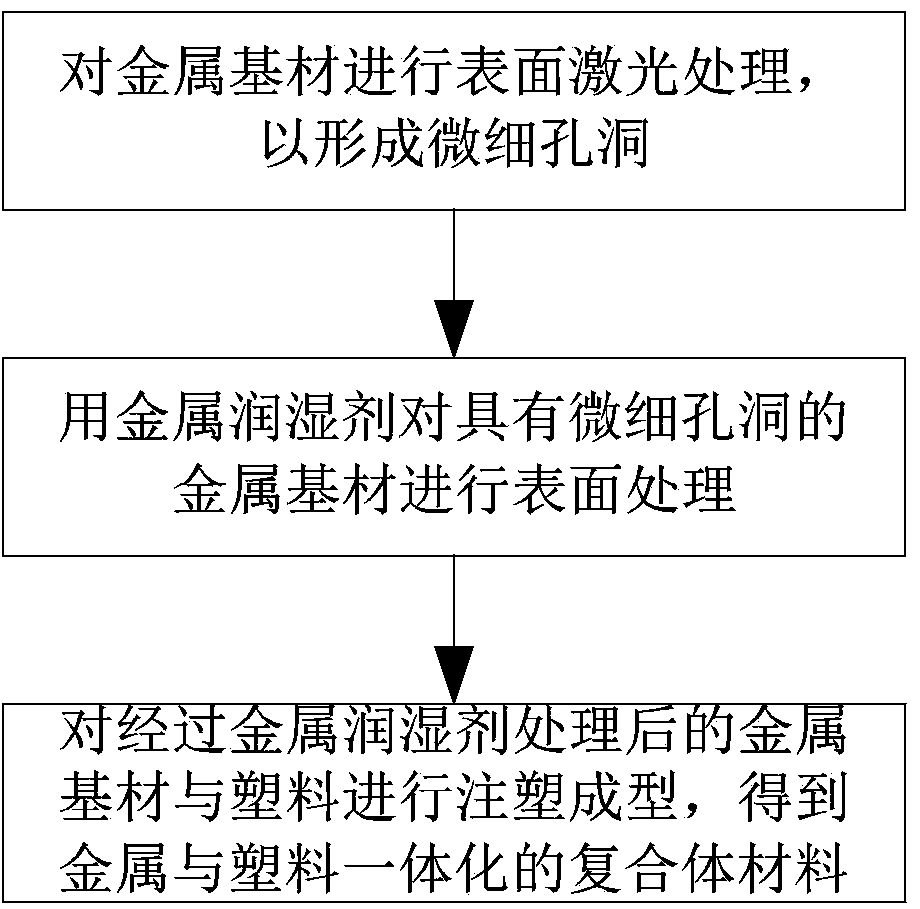

[0037] refer to figure 1 , according to an embodiment of the present invention, the preparation method of the composite material includes the following steps:

[0038] Surface laser treatment of metal substrates to form fine holes;

[0039] Surface treatment of metal substrates with fine pores with metal wetting agents;

[0040] Injection molding the metal substrate and plastic treated with metal wetting agent to obtain a composite material integrating metal and plastic;

[0041] Wherein, the metal wetting agent contains an organic acid agent for improving the difference in surface tension coefficient between the metal substrate and the plastic.

[0042] The materials used in carrying out the method of the present invention are as follows.

[0043] 1. Metal: The metal can be a metal substrate formed by machining, and can be but not limited to one of stainless steel, titanium alloy, aluminum alloy, magnesium alloy and copper alloy.

[0044] 2. Plastic: said plastic can be b...

Embodiment 1

[0063] Metal wetting agents include the following components:

[0064] In 1000 parts of solvent (wherein water 700 parts, ethanol 300 parts), be furnished with the raw material component of following weight ratio:

[0065] 1) 105 parts of concentrated hydrochloric acid;

[0066] 2) 200 parts of organic acids, including: 120 parts of maleic acid and 80 parts of malic acid.

[0067] The preparation method of composite material comprises the following steps:

[0068] 1) Provide a metal substrate formed by machining, mainly involving one of stainless steel, titanium alloy, aluminum alloy, magnesium alloy and copper alloy.

[0069] 2) Carry out chemical degreasing treatment on the metal substrate with a degreasing agent sold on the market to remove oil stains on the metal surface; the chemical degreasing temperature is 85°C, and the degreasing time depends on the specific degreasing effect.

[0070] 3) Perform surface ultraviolet laser treatment on the degreasing metal substrate...

Embodiment 2

[0077] Metal wetting agents include the following components:

[0078] In 1000 parts of solvent (wherein water 700 parts, ethanol 300 parts), be furnished with the raw material component of following weight ratio:

[0079] 1) 65 parts of concentrated hydrochloric acid;

[0080] 2) 200 parts of organic acids, including: 105 parts of maleic acid and 95 parts of malic acid.

[0081] The preparation method of composite material comprises the following steps:

[0082] 1) Provide a metal substrate formed by machining, mainly involving one of stainless steel, titanium alloy, aluminum alloy, magnesium alloy and copper alloy.

[0083] 2) Carry out chemical degreasing treatment on the metal substrate with a degreasing agent sold on the market to remove oil stains on the metal surface; the chemical degreasing temperature is 85°C, and the degreasing time depends on the specific degreasing effect.

[0084] 3) Perform surface ultraviolet laser treatment on the degreasing metal substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com