Desulfurization method for purifying flue gas

A flue gas purification and flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high regeneration energy consumption, easy generation of side reactions, and high liquid-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

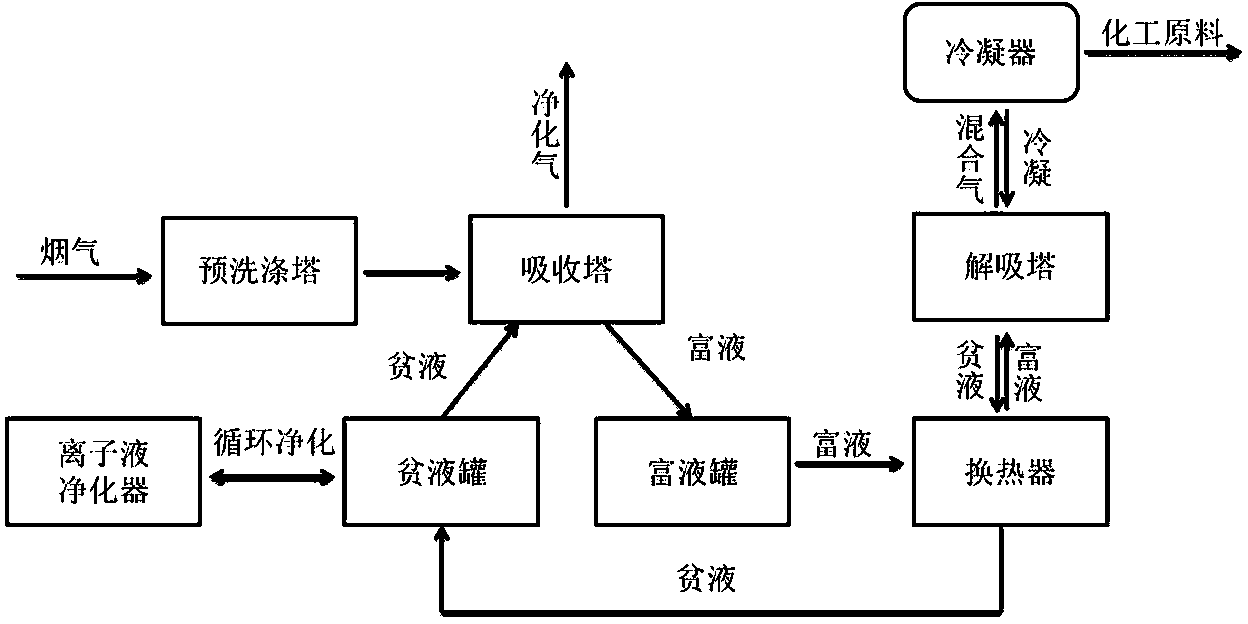

Method used

Image

Examples

Embodiment 1

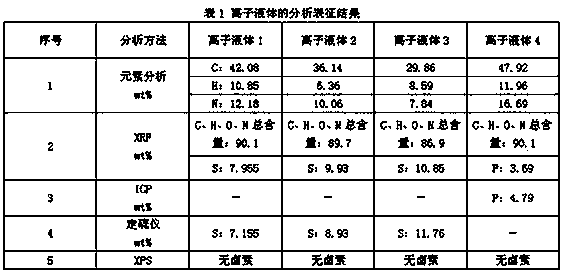

[0044] Preparation of ionic liquid:

[0045] Using different amine compounds, the elimination reactions were carried out under the following conditions: 60 °C, 24 h, 120 °C, 2 h, 100 °C, 6 h, 50 °C, 12 h, and the products were purified by vacuum distillation to obtain four different compounds. Use sulfuric acid or phosphoric acid to carry out neutralization reaction, and after concentrated treatment, carry out drying treatment under the following conditions: 25 ℃, 0.1 kPa, 12h, 120 ℃, 100 kPa, 10h, 65 ℃, 0.1 kPa, 12 h, 100 ℃, 0.1kPa, 2h. Ionic liquids 1, 2, 3, and 4 were obtained, respectively.

[0046] The ionic liquids 1, 2, 3, and 4 are uniformly mixed with an ionic solvent at a certain concentration to obtain different ionic solutions.

Embodiment 2

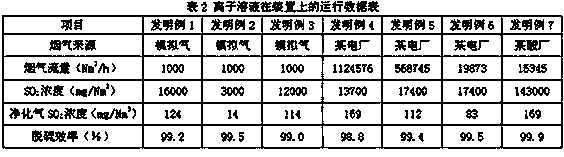

[0048] Use the desulfurization process in this patent to desulfurize the simulated gas:

[0049] For laboratory simulated gas, the gas flow is 1000 Nm 3 / h, where SO 2 Concentration is 16000 mg / Nm 3 , SO in purified gas after desulfurization 2 The concentration is 124 mg / Nm 3 , The desulfurization efficiency is 99.2%.

Embodiment 3

[0051] Use the desulfurization process in this patent to desulfurize the simulated gas:

[0052] For laboratory simulated gas, the gas flow is 1000 Nm 3 / h, where SO 2 At a concentration of 3000 mg / Nm 3 , SO in purified gas after desulfurization 2 The concentration is 14 mg / Nm 3 , The desulfurization efficiency is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com