Production method for powder containing crystalline alpha, alpha-trehalose dihydrate

A technology of dihydrate and crystalline powder, which is applied in the preparation of sugar derivatives, biochemical equipment and methods, sugar derivatives, etc., can solve the problems such as inability to obtain, and achieve easy cultivation, high crystallinity, and excellent starch yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0275]

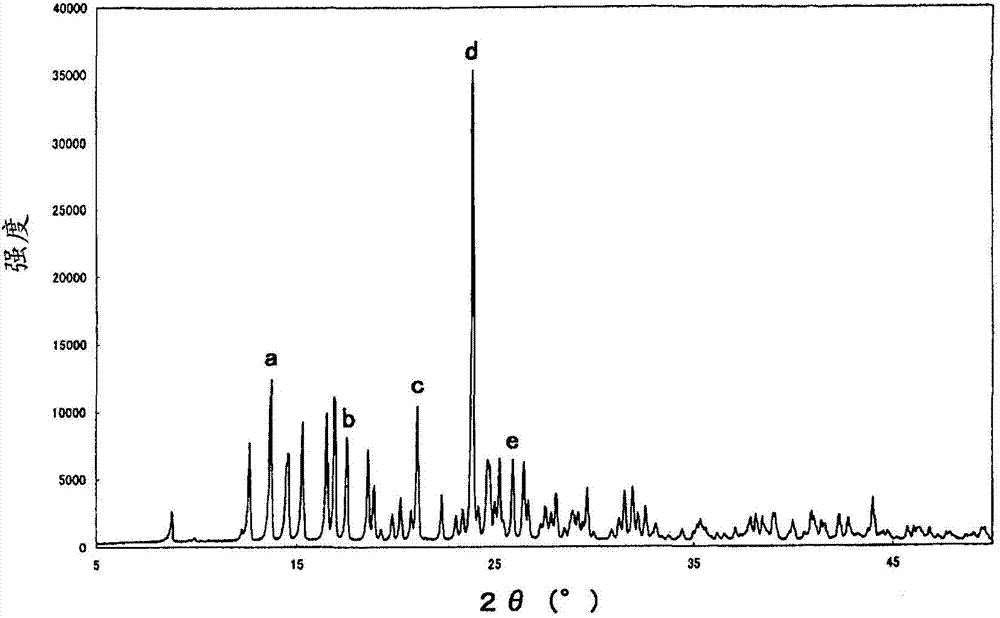

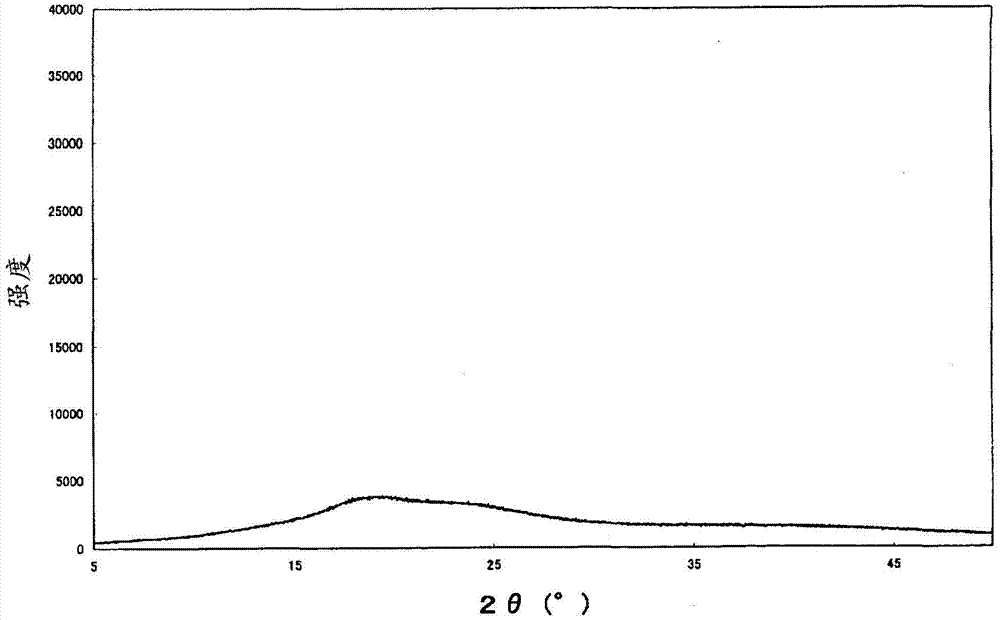

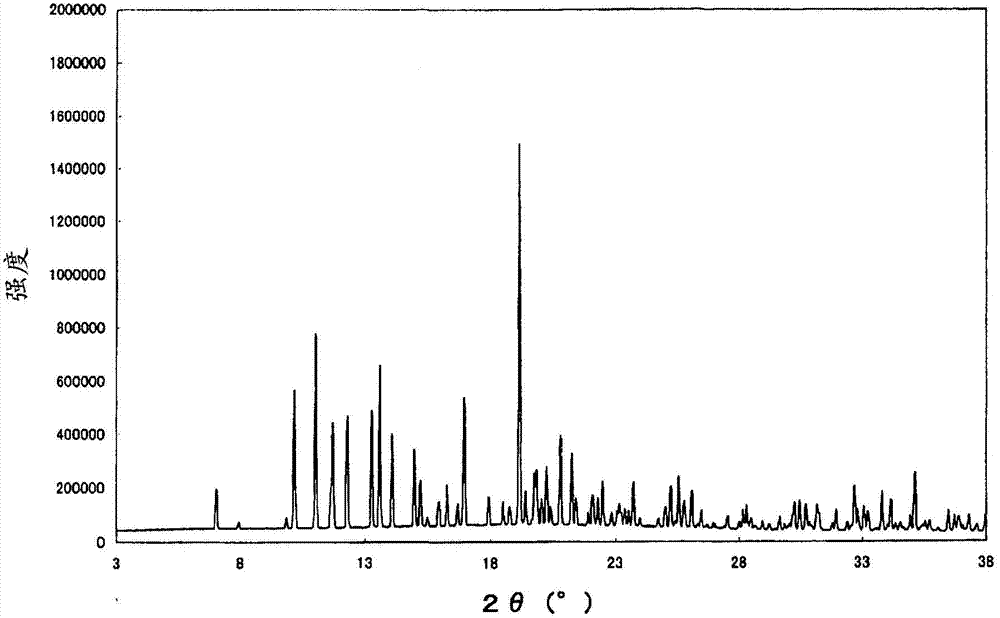

[0276] Corn starch was suspended in water so as to be 30%, and calcium carbonate was added to this suspension to have a final concentration of 0.1%, and the pH was adjusted to 6.0. To this suspension, add 0.2% based on the mass of starch of heat-resistant α-amylase (trade name "Kumamamil 60L", sold by Nobozaimzu Japan Co., Ltd.), react at 98 to 100°C for 15 minutes, and Starch gelatinization - liquefaction. After the obtained liquefied starch solution was treated in an autoclave at 125°C for 15 minutes, it was cooled to 51°C. To this solution, 2 units and 10 units of α- Partially refined enzyme solution of glycosyl trehalose synthase and trehalose separation enzyme, in addition, 300 units of isoamylase (manufactured by Hayashibara Co., Ltd.) per 1 gram of starch, and 2 units of isoamylase derived from experiments 1-2 The prepared CGTase of Paenibacillus illinois NBRC15959 strain was further reacted for about 70 hours. Next, this reaction solution was heated at 97°...

Embodiment 2

[0279]

[0280] Using 3 units and 15 units of α-glycosyl trehalose synthase and trehalose separation enzyme per 1 gram of starch respectively, the reaction time reaches 40 hours. Except for the CGTase of Paenibacillus NBRC15379 strain, trehalose production reaction and glucoamylase treatment were performed in the same manner as in Example 1, thereby obtaining the purity of trehalose, that is, the purity of trehalose in terms of anhydrous matter. A reaction solution with a trehalose content of 87.6%. Heating the obtained reaction solution to inactivate the enzyme, decolorize and filter the filtrate through activated carbon according to conventional methods, desalt the filtrate with cation exchange resin (H+ type) and anion exchange resin (OH- type), and concentrate under reduced pressure to form a solid concentration of about 85 % concentrate. Put it in an auxiliary crystallization tank, add 1% reagent-grade powder containing trehalose dihydrate crystals (trade name "trehalo...

Embodiment 3

[0284]

[0285]As the CGTase, except that the CGTase derived from the Paenibacillus NBRC13638 strain prepared by the method of Experiment 1-2 was used, in the same manner as in Example 1, the trehalose production reaction was performed, and then the glucoamylase The trehalose content of the reaction liquid after the treatment was 87.2% in terms of anhydrous. The reaction liquid thus obtained is heated to inactivate the enzyme, and decolorized and filtered through activated carbon according to a conventional method, and the filtrate is desalted with a cation exchange resin (H+ type) and an anion exchange resin (OH- type), and concentrated under reduced pressure to form a solid concentration About 85% concentrate. Put it in an auxiliary crystallization tank, add 1% reagent-grade powder containing trehalose dihydrate crystals (trade name "trehalose 999", code number: TH224, trehalose purity 99.9% or more, sold by Hayashibara Co., Ltd.) As a seed crystal, bring it to 60°C while...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com