Battery diaphragm formed by aramid fibers and preparation method thereof

A technology of battery separator and aramid fiber, applied in the field of battery separator and its preparation, can solve the problems of poor air permeability of polyolefin separator, unable to meet the fast charging and discharging of battery, affecting the cycle life of battery, etc., and achieve excellent mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

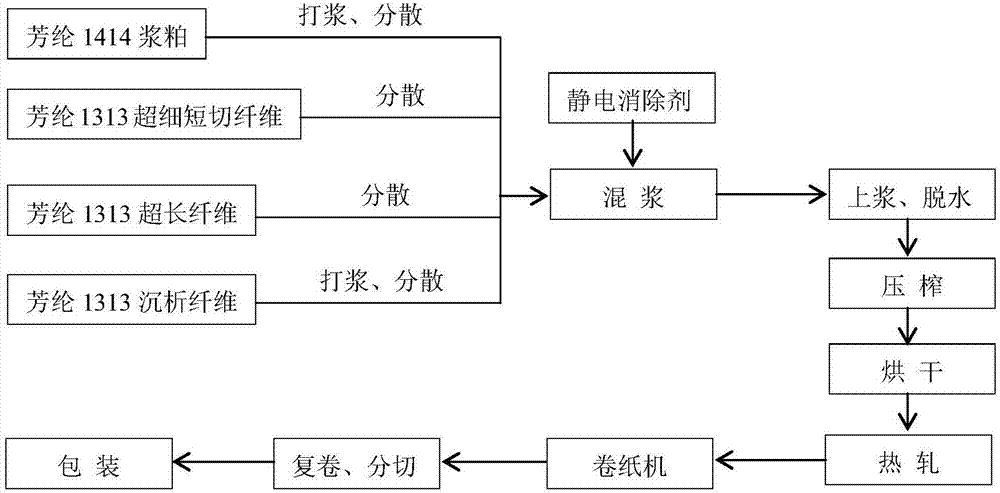

Method used

Image

Examples

Embodiment 1

[0028] Weighing of raw materials: Weigh raw materials according to the following mass ratios: 80% of aramid 1414 pulp, 10% of aramid 1313 ultrafine chopped fibers, and 10% of aramid 1313 precipitated fibers;

[0029] Raw material pretreatment: Prepare the weighed raw materials to make aqueous solution respectively, the preparation process is as follows:

[0030] A. Use deionized water to prepare aramid 1414 pulp into an aqueous solution with a concentration of 10%, beating until the degree of beating is 25°SR, and then disperse evenly in deionized water to prepare aramid 1414 pulp with a concentration of 0.1% aqueous solution;

[0031] B. Aramid 1313 ultrafine chopped fibers are uniformly dispersed in deionized water, and the concentration is prepared into an aqueous solution of 0.04% aramid 1313 ultrafine chopped fibers;

[0032] C. Use deionized water to prepare aramid 1313 precipitated fiber into an aqueous solution with a concentration of 0.1%, beating until the degree of...

Embodiment 2

[0037] Weighing of raw materials: Weigh raw materials according to the following mass ratios: 10% of aramid 1414 pulp, 40% of aramid 1313 superfine chopped fibers, 10% of aramid 1313 ultra-long fibers, and 40% of aramid 1313 precipitated fibers;

[0038] Raw material pretreatment: Prepare the weighed raw materials to make aqueous solution respectively, the preparation process is as follows:

[0039] A. Use deionized water to prepare aramid 1414 pulp into an aqueous solution with a concentration of 30%, beating until the degree of beating is 70°SR, and then disperse evenly in deionized water to prepare aramid 1414 pulp with a concentration of 1%. aqueous solution;

[0040] B. Aramid 1313 ultrafine chopped fibers are uniformly dispersed in deionized water, and the concentration is prepared into an aqueous solution of 0.5% aramid 1313 ultrafine chopped fibers;

[0041] C. the aramid 1313 ultra-long fiber is uniformly dispersed in deionized water by an ultrasonic dispersion proce...

Embodiment 3

[0047] Weighing of raw materials: Weigh raw materials according to the following mass ratios: 40% of aramid 1414 pulp, 5% of aramid 1313 superfine chopped fibers, 5% of aramid 1313 ultra-long fibers, and 50% of aramid 1313 precipitated fibers;

[0048] Raw material pretreatment: Prepare the weighed raw materials to make aqueous solution respectively, the preparation process is as follows:

[0049] A. Use deionized water to prepare aramid 1414 pulp into an aqueous solution with a concentration of 15%, beating until the degree of beating is 30°SR, and then disperse evenly in deionized water to prepare aramid 1414 pulp with a concentration of 0.5% aqueous solution;

[0050] B. Aramid 1313 ultrafine chopped fibers are uniformly dispersed in deionized water, and the concentration is prepared into an aqueous solution of 0.2% aramid 1313 ultrafine chopped fibers;

[0051] C. the aramid 1313 ultra-long fibers are uniformly dispersed in deionized water by an ultrasonic dispersion proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com