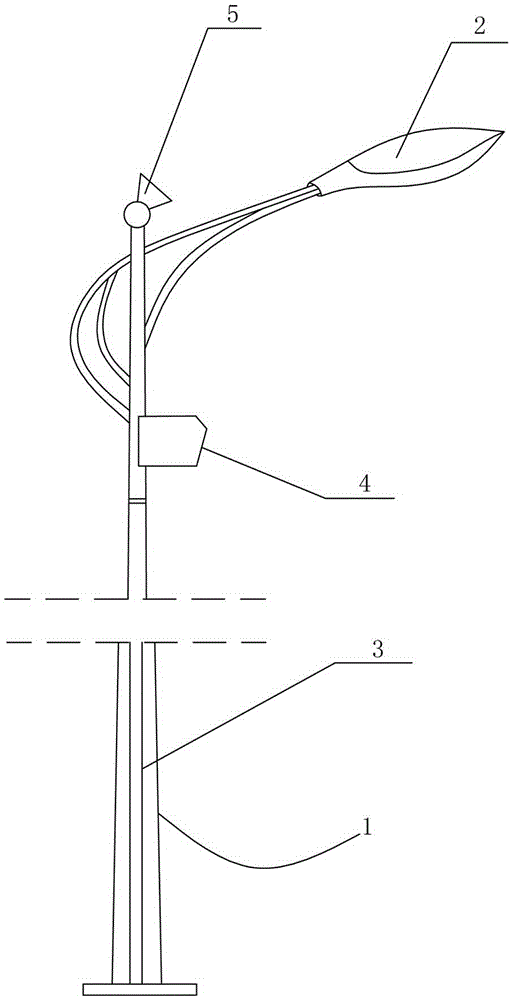

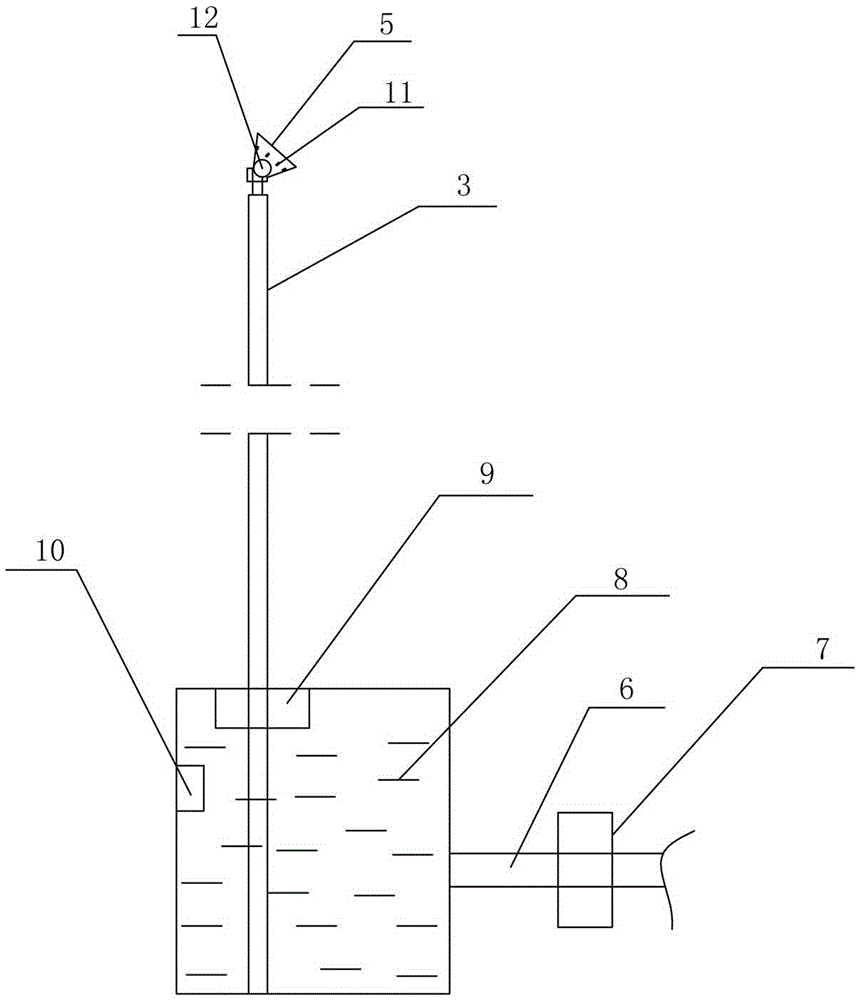

led street light for city viaduct

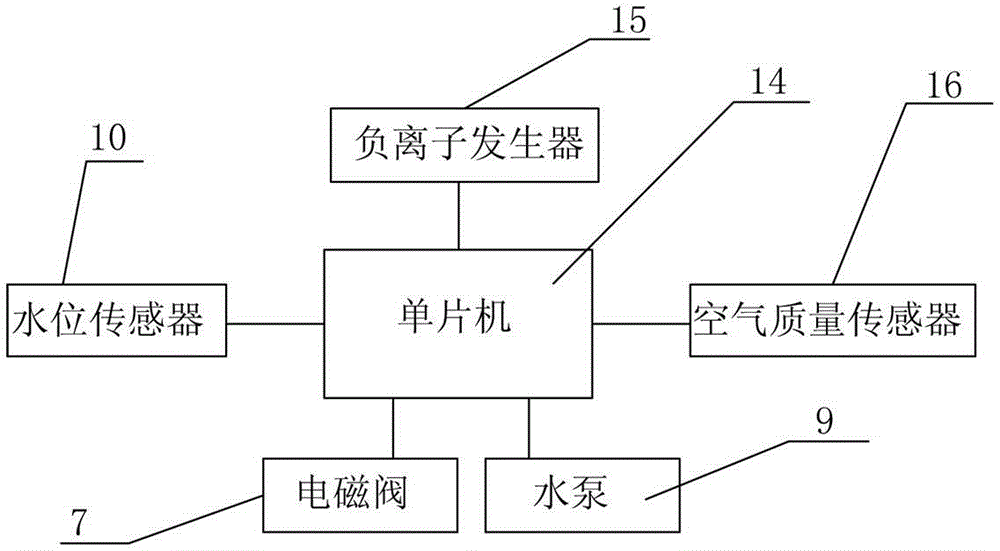

A technology for LED street lamps and viaducts, which is applied to outdoor lighting, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of water spraying system not working normally, inconvenient maintenance or replacement, and small space for street lamp poles, etc. To achieve the effect of good thermal insulation, long service life and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The components and parts by weight of the insulation pipe 13 are: 100 parts of polyvinyl chloride, 12 parts of azodicarbonamide, 1.2 parts of sodium bicarbonate, 10 parts of urea-formaldehyde, 0.5 parts of dicumyl peroxide, ethylene-vinyl acetate 5 parts of copolymer, 0.6 parts of silicon dioxide. This insulation pipe 13 adopts following method to prepare:

[0030] S1: Prepare the raw materials according to the components and parts by weight of the above-mentioned insulation pipes, and then put them into the material box and mix them evenly;

[0031] S2: Heat the material box until the material melts. When the temperature is 160°C-165°C, after the azodicarbonamide and sodium bicarbonate are fully foamed, the molten material is extruded by a screw extruder.

[0032] The data of the density, tensile strength and thermal conductivity of the prepared insulation pipe are shown in Table 1.

Embodiment 2

[0034] The components and parts by weight of the insulation pipe 13 are: 100 parts of polyvinyl chloride, 6 parts of azodicarbonamide, 1.5 parts of sodium bicarbonate, 20 parts of urea formaldehyde, 0.8 parts of dicumyl peroxide, ethylene-vinyl acetate 10 parts of copolymer, 0.8 parts of silicon dioxide. This insulation pipe 13 adopts following method to prepare:

[0035] S1: Prepare the raw materials according to the components and parts by weight of the above-mentioned insulation pipes, and then put them into the material box and mix them evenly;

[0036] S2: Heat the material box until the material is melted. When the temperature is 165°C-170°C, after the azodicarbonamide and sodium bicarbonate are fully foamed, the molten material is extruded by a screw extruder.

[0037] The data of the density, tensile strength and thermal conductivity of the prepared insulation pipe are shown in Table 1.

Embodiment 3

[0039] The components and parts by weight of the insulation pipe 13 are: 100 parts of polyvinyl chloride, 14 parts of azodicarbonamide, 1.3 parts of sodium bicarbonate, 17 parts of urea formaldehyde, 0.7 parts of dicumyl peroxide, ethylene-vinyl acetate 8 parts of copolymer, 0.7 parts of silica. This insulation pipe 13 adopts following method to prepare:

[0040] S1: Prepare the raw materials according to the components and parts by weight of the above-mentioned insulation pipes, and then put them into the material box and mix them evenly;

[0041] S2: Heat the material box until the material is melted. When the temperature is 165°C-170°C, after the azodicarbonamide and sodium bicarbonate are fully foamed, the molten material is extruded by a screw extruder.

[0042] The data of the density, tensile strength and thermal conductivity of the prepared insulation pipe are shown in Table 1.

[0043] The test data is as follows:

[0044] Example / Test Item

[0045] It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com