Gear transmission mechanism of electrode coping and cap replacing all-in-one machine

A technology of gear transmission mechanism and integrated machine, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problem of increasing the cost of the machine, and achieve the effect of reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

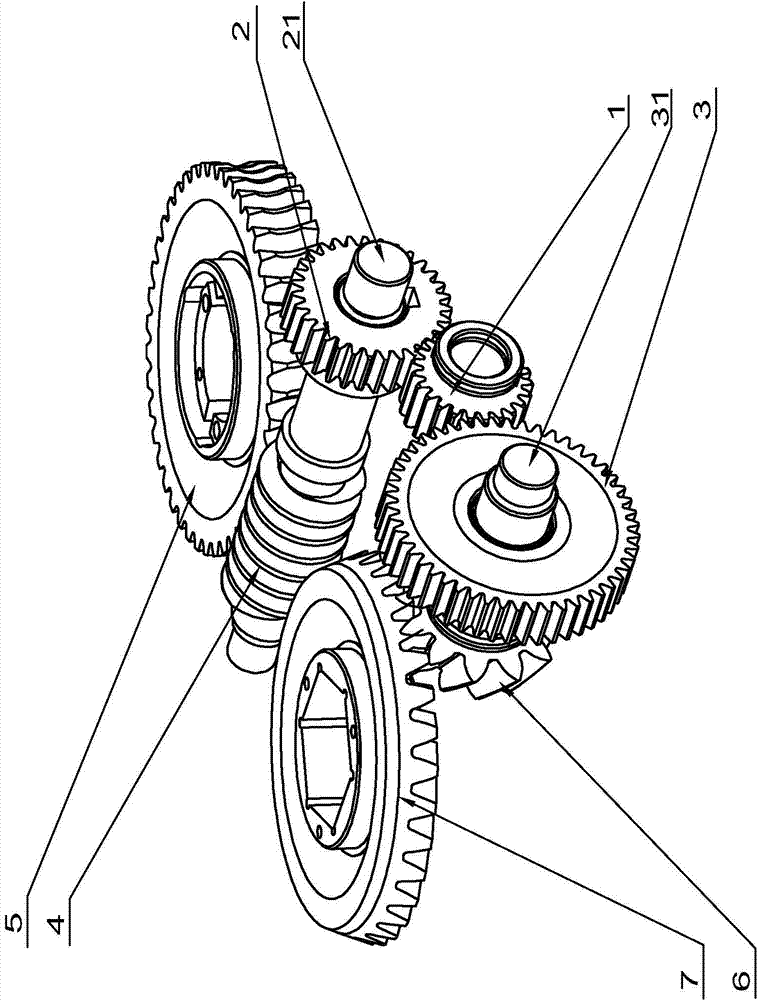

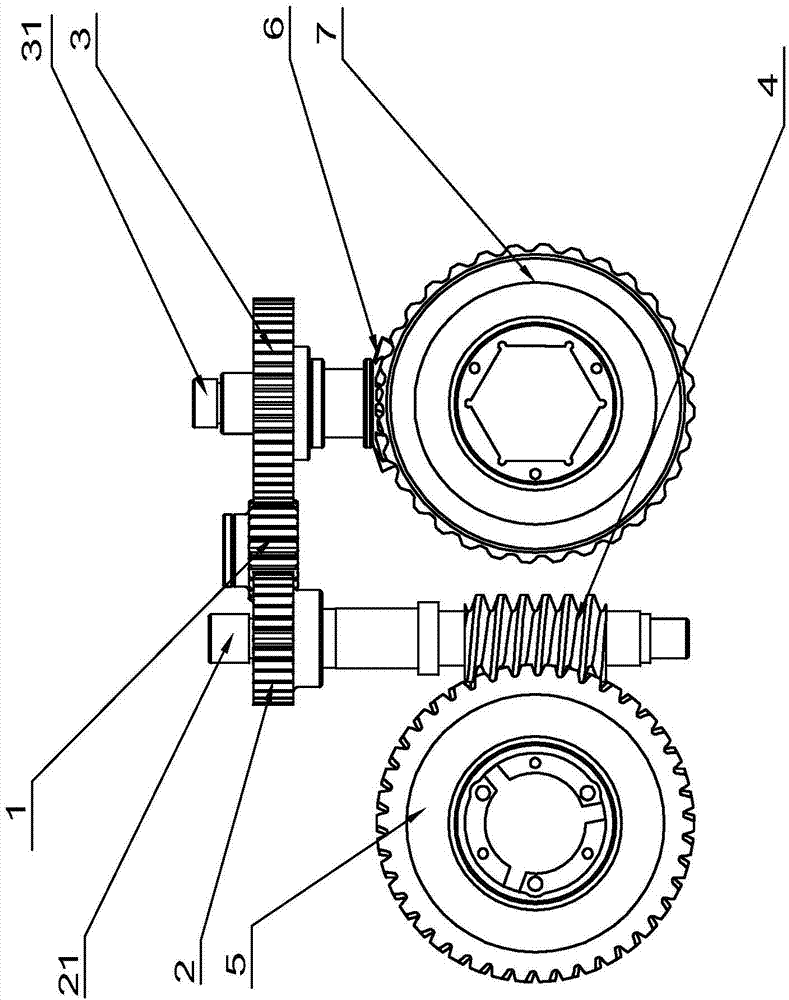

[0016] refer to figure 1 , figure 2 , the present invention is a gear transmission mechanism of an electrode repairing and cap changing integrated machine, comprising a driving spur gear 1, a cap removal driving spur gear 2 meshing with the driving spur gear 1 and an electrode grinding driving spur gear 3, and a cap removal driving spur gear 3 The spur gear 2 is connected with a worm shaft 4 and a worm wheel 5 driven by the cap removal drive spur gear 2 and meshed with each other, and connected with the electrode grinding drive spur gear 3 is provided with a drive bevel gear 6 driven by the electrode grinder drive spur gear 3 And electrode grinding bevel gear 7.

[0017] The gear transmission mechanism of the electrode dressing and cap changing all-in-one machine drives the worm shaft 4 and the worm wheel 5 meshing with each other on both sides by setting the cap removing drive spur gear 2 and the electrode grinding drive spur gear 3 respectively on both sides of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com