Steel pipe with ultrahigh strength and continuous production method of steel pipe

An ultra-high-strength, production method technology, applied in the field of metal and steel, can solve the problems of high manufacturing cost, low production operation rate, increase manufacturing cost, etc., to save production time and operation intensity, improve production operation rate, and reduce production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0014] Embodiments 1-6: The ultra-high-strength steel pipes use the following raw materials and continuous production methods.

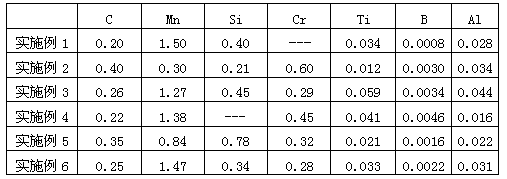

[0015] Steel raw material: See Table 1 for the chemical composition ratio of the steel used in this ultra-high-strength steel pipe.

[0016] Table 1: Chemical Composition of Steel Raw Materials (wt%)

[0017]

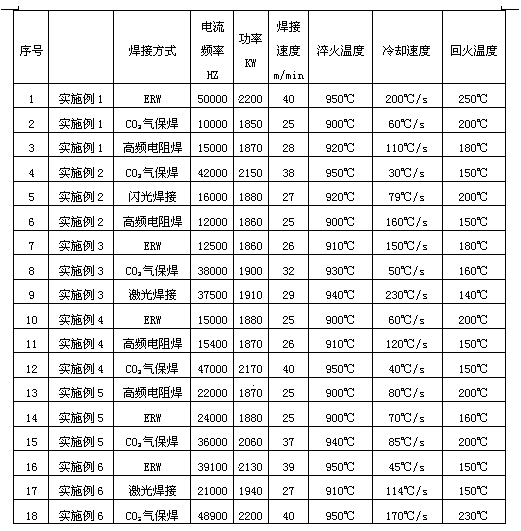

[0018] Production process: After the above-mentioned steel plate or steel coil is crimped and formed, it is made into the ultra-high-strength steel pipe through a welding production line and a heat treatment production line; the welding production line includes pipe coiling, welding, deburring and skin-finishing processes; the heat treatment production line is installed Behind the welding production line, including high-frequency quenching, medium-frequency tempering and shot peening processes.

[0019] The specific process flow is: steel plate or steel coil - slitting into strips - decoiling - coiling - welding - deburring - skin pass - h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com