High-temperature-resistant and low-tension foam flooding agent and preparation method thereof

A foam flooding and low tension technology, applied in the field of foam oil flooding agent, can solve the problems of poor high temperature resistance, limited application, poor compatibility, etc., and achieve the effects of increasing cost, good foam stability and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

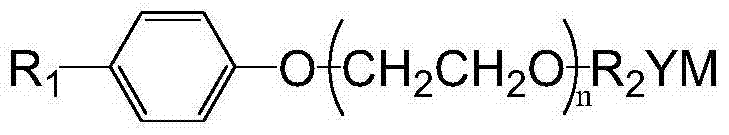

Method used

Image

Examples

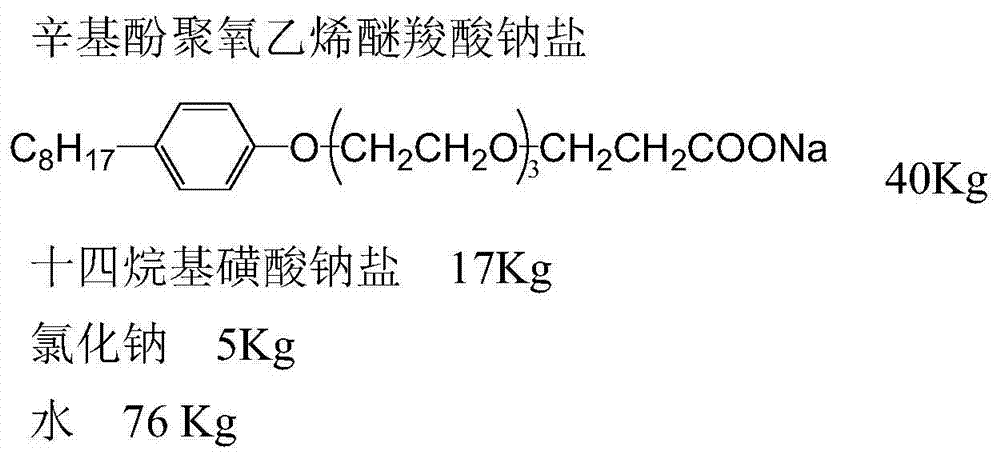

Embodiment 1

[0024] raw material:

[0025]

[0026] Preparation method: Add 50Kg of water into the reaction kettle, at a temperature of 30°C, add 40Kg of octylphenol polyoxyethylene ether carboxylate sodium salt and 17Kg of tetradecylsulfonic acid sodium salt, and stir; to be reacted After the sodium salt of octylphenol polyoxyethylene ether carboxylate and sodium tetradecyl sulfonate in the still are dissolved, add 5Kg of sodium chloride and the remaining 26Kg of water, stir and mix well to obtain light yellow transparent High temperature low tension foam oil displacing agent.

[0027] The high-temperature-resistant low-tension foam oil-displacing agent prepared above does not decompose at a high temperature of 250° C.

[0028] Use the above-mentioned high-temperature-resistant low-tension foam oil-displacement agent prepared above and the aqueous solution of the described high-temperature-resistant low-tension foam oil-displacement agent with a concentration of 0.4wt% to carry out la...

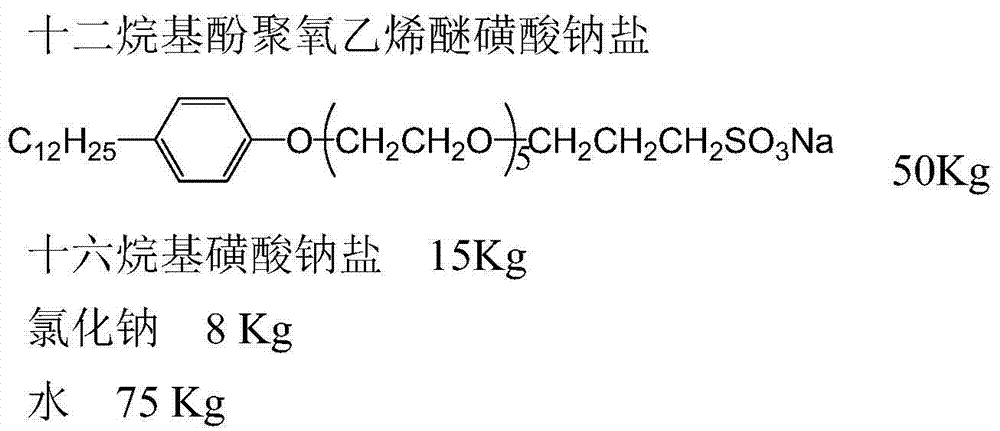

Embodiment 2

[0031] raw material:

[0032]

[0033]Preparation method: Add 50Kg of water into the reaction kettle, add 50Kg of sodium dodecylphenol polyoxyethylene ether sulfonate and 15Kg of sodium hexadecylsulfonate at a temperature of 35°C, and stir; After the dodecylphenol polyoxyethylene ether sulfonic acid sodium salt and hexadecyl sulfonic acid sodium salt in the reaction kettle are dissolved, add 8Kg of sodium chloride and the remaining 25Kg of water, stir and mix well to obtain the light Yellow transparent high temperature resistant low tension foam oil displacing agent.

[0034] The high-temperature-resistant low-tension foam oil-displacing agent obtained above does not decompose at a high temperature of 250° C.

[0035] Use the above-mentioned high-temperature-resistant low-tension foam oil-displacement agent prepared above and the aqueous solution of the described high-temperature-resistant low-tension foam oil-displacement agent with a concentration of 0.4wt% to carry out ...

Embodiment 3

[0038] raw material:

[0039]

[0040] Preparation method: Add 78Kg of water into the reaction kettle, and at a temperature of 30°C, add 70Kg of nonylphenol polyoxyethylene ether carboxylate sodium salt and 28Kg of sodium tetradecylsulfonate sodium salt, and stir; After dissolving the sodium salt of nonylphenol polyoxyethylene ether carboxylate and sodium tetradecyl sulfonate in the reaction kettle, add 10Kg of sodium chloride and the remaining 39Kg of water, stir and mix well to obtain light yellow and transparent High temperature resistant low tension foam oil displacing agent.

[0041] The high-temperature-resistant low-tension foam oil-displacing agent obtained above does not decompose at a high temperature of 250° C.

[0042] Use the above-mentioned high-temperature-resistant low-tension foam oil-displacement agent prepared above and the aqueous solution of the described high-temperature-resistant low-tension foam oil-displacement agent with a concentration of 0.4wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com