Method for preparing NiTi spring/carbon nano-tube/polyurethane composite material

A technology of carbon nanotubes and composite materials, applied in the field of preparation of composite functional materials, can solve the problems of poor dispersion effect, increased production cost, poor overall fluidity of resin matrix, etc., and achieves improved dispersion effect, low cost, and elimination of Effects of tissue defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

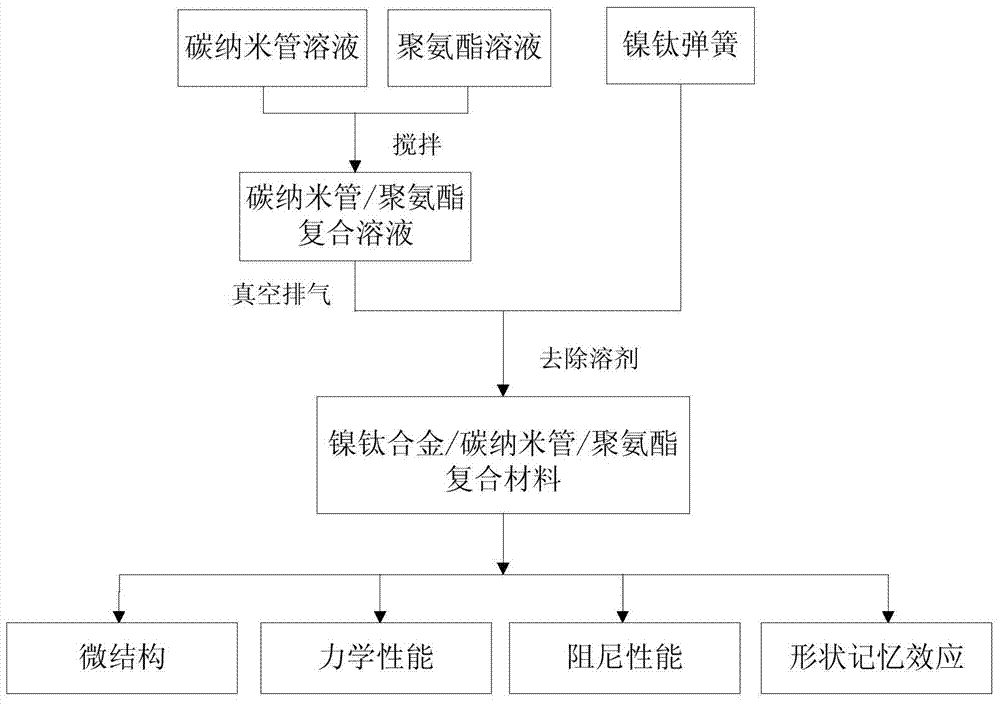

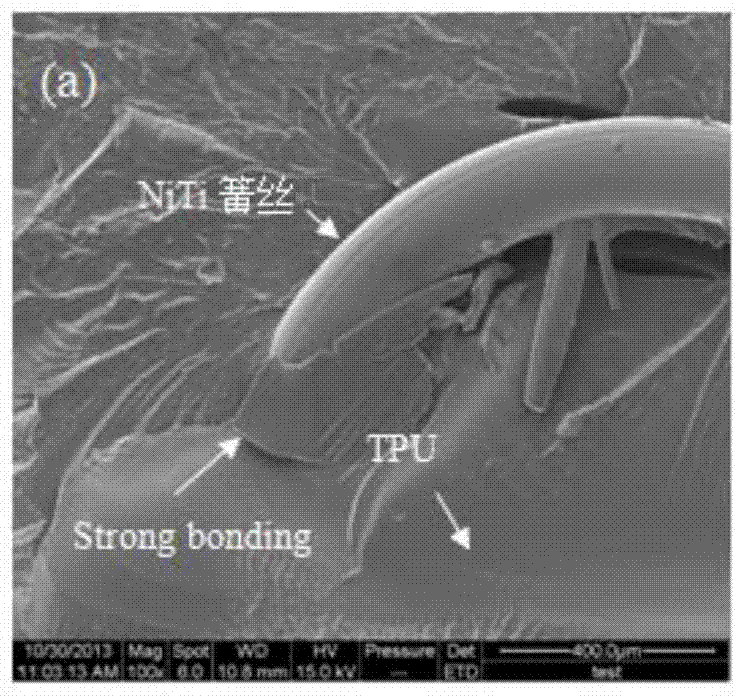

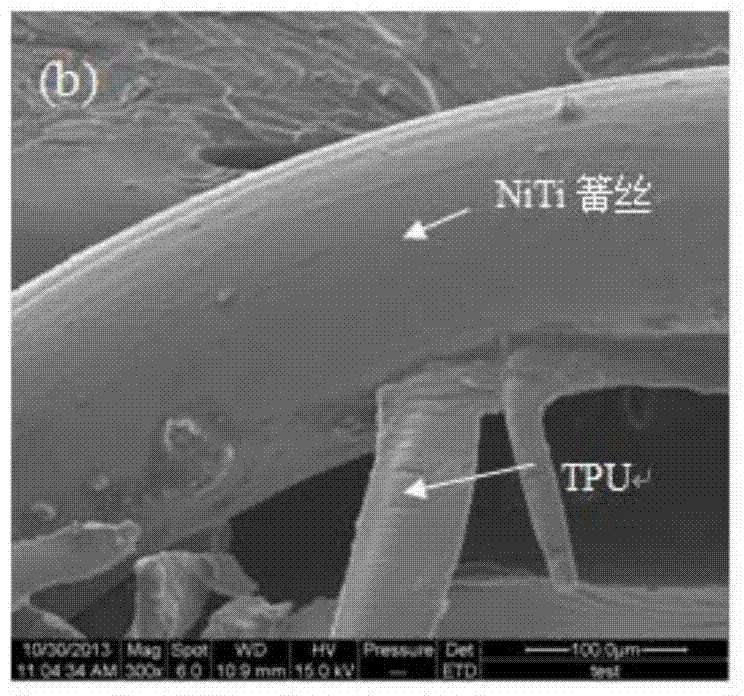

[0026] The basic steps of the present invention for preparing a NiTi alloy spring and carbon nanotube composite doped polyurethane composite material by using a solution forming method are: (1) Dissolving carbon nanotube (CNT) and polyurethane elastomer (TPU) particles in an organic solvent respectively Disperse the CNT solution ultrasonically for 1h~3h, then place the TPU solution in a magnetic stirrer and stir. At the same time, add the dispersed CNT solution dropwise to the TPU solution to make the CNT uniformly dispersed in the TPU solution. 0.1~1wt%; (2) Put the CNT-TPU mixed solution in a vacuum drying box to exhaust, and keep the temperature at 70~100℃ for 0.5h~1.5h; (3) Put the NiTi alloy spring into acetone Medium ultrasonic cleaning; (4) Slowly embed the NiTi alloy spring into the CNT-TPU mixed system of step (2). (5) The solvent is removed in a blast thermostat, and the composite material is molded. The temperature is maintained at 70-100°C, and the molding time is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com