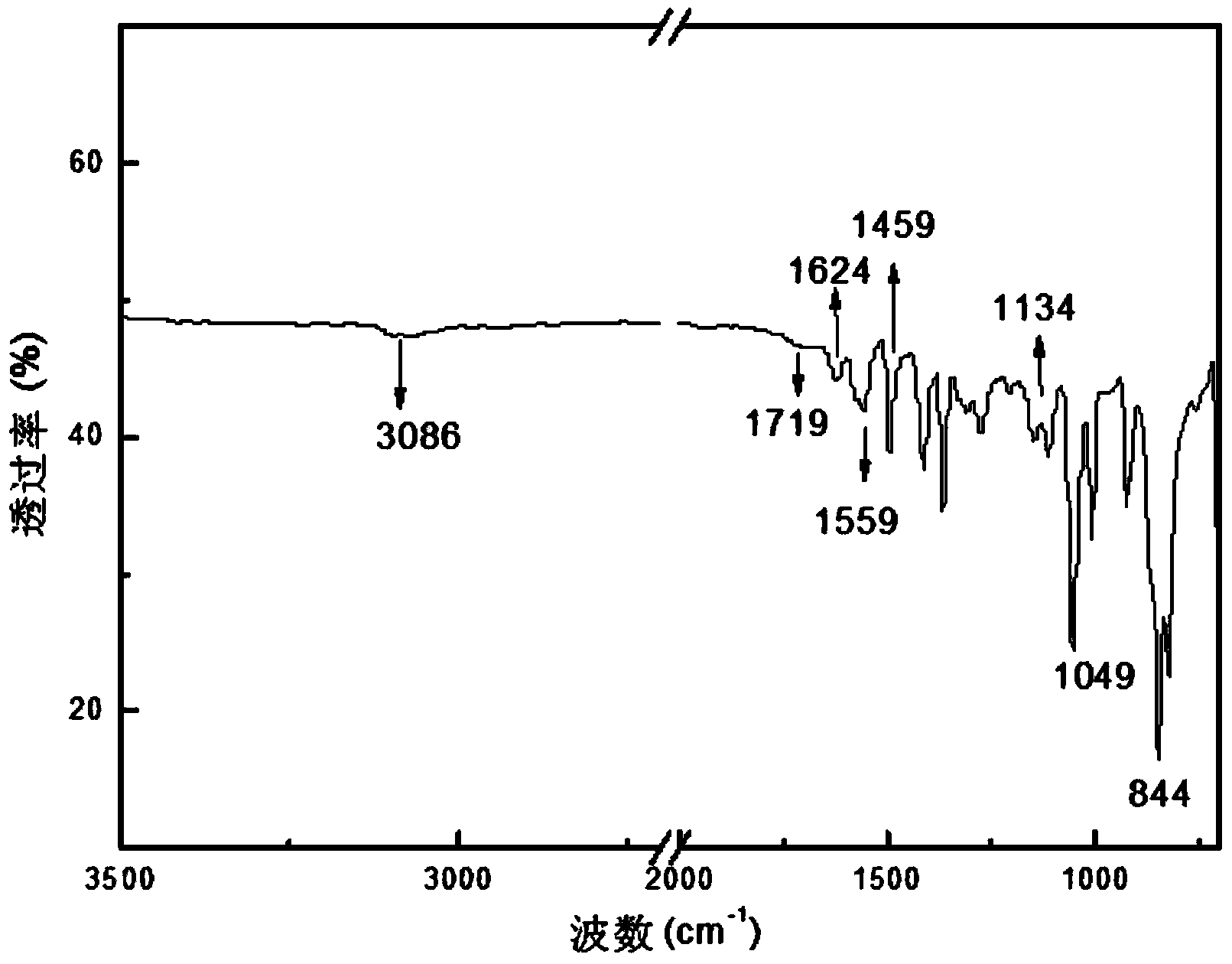

Graphene nanobelt graft modified PBO polymer and preparation method thereof

A graphene nanoribbon, PBO polymer technology, applied in the field of modified PBO polymer and its preparation, can solve the problems of low tensile strength of PBO fiber, and achieve the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

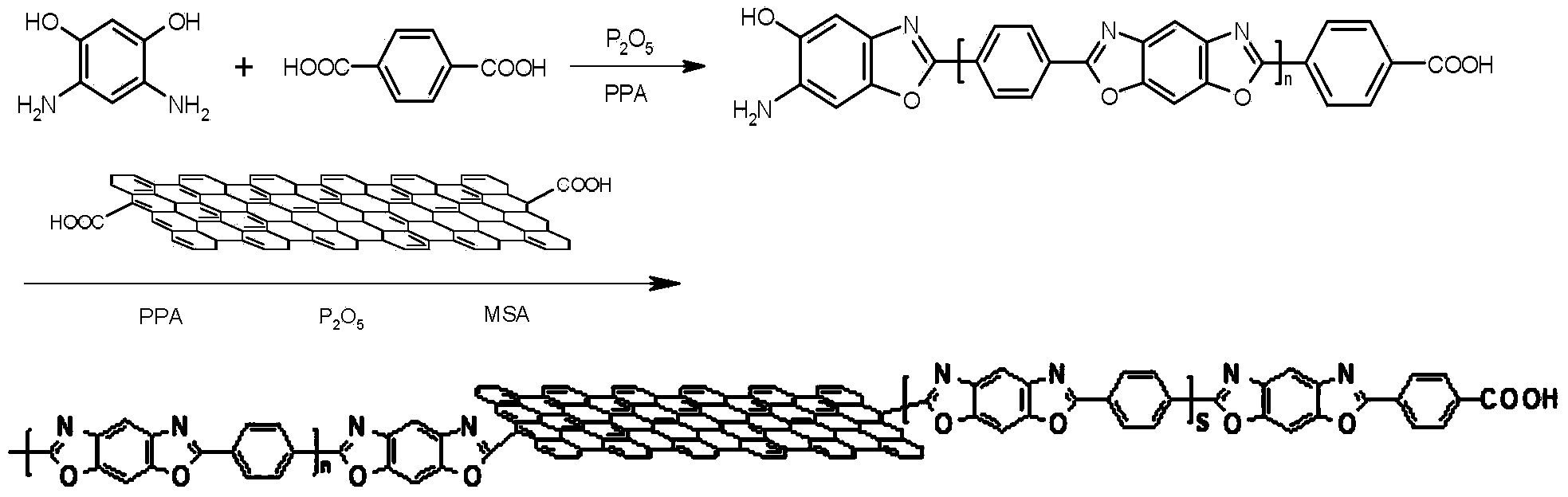

[0020] Specific embodiment two: the preparation method of a kind of graphene nanoribbon graft modification PBO polymer described in specific embodiment one, carry out according to the following steps:

[0021] 1. Add phosphorus pentoxide to phosphoric acid, stir and dissolve the polyphosphoric acid solution;

[0022] Two, adding the carboxylated graphene nanobelts to the polyphosphoric acid solution prepared in step 1, stirring for 0.5 to 2 hours to obtain a dispersed solution of the carboxylated graphene nanobelts;

[0023] 3. Mix and stir the PBO polymer and methanesulfonic acid for 4 to 24 hours to obtain a PBO solution;

[0024] 4. Mix the carboxylated graphene nanoribbon dispersion obtained in step 2 with the PBO solution obtained in step 3, then stir and react at a temperature of 100°C to 180°C for 12 to 48 hours to obtain a reaction product, and wash the reaction product with water After drying, the obtained graphene nanobelts are grafted to a modified PBO polymer.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 in that the mass ratio of phosphorus pentoxide to phosphoric acid in step 1 is 1: (1-2). Others are the same as in the first embodiment.

specific Embodiment approach 4

[0026] Embodiment 4: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of carboxylated graphene nanoribbons to polyphosphoric acid solution in step 2 is 1: (50-1000). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com