Method for synchronously obtaining carbon dioxide absorbent along with production of acetylene

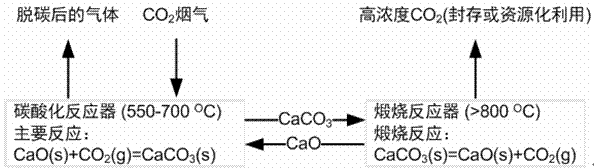

A technology of carbon dioxide and simultaneous acquisition, applied in chemical instruments and methods, separation methods, reagents, etc., can solve the problems of large attenuation coefficient of absorbent, ineffective utilization, carbide slag pollution, etc., to avoid carbon dioxide problems, alleviate sintering, widen The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

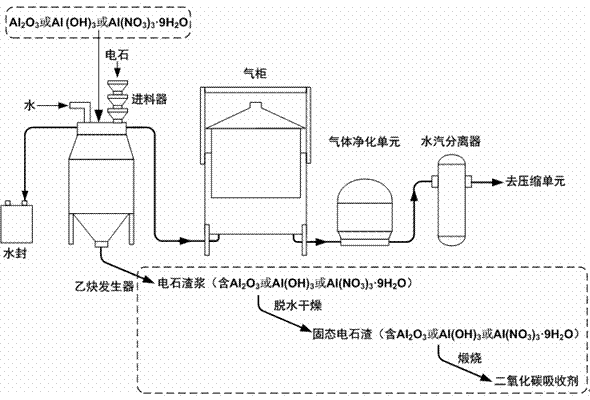

[0035] The method for synchronously obtaining a carbon dioxide absorbent with the production of acetylene described in this embodiment specifically includes the following steps, such as figure 2 Shown:

[0036] (1) Add alumina, calcium carbide, and water into the reactor at the same time, wherein the mass ratio of alumina to calcium carbide is 7:100, and the mass ratio of water to calcium carbide is 350:100. After fully reacting, the mixture of calcium carbide and slurry is obtained. ;

[0037] (2) Dehydrate the calcium carbide slag slurry mixture obtained in step (1), and then dry it at a constant temperature at 100 °C for 24 hours to obtain solid carbide slag;

[0038] (3) The solid carbide slag obtained in step (2) was calcined in a muffle furnace at a constant temperature of 850 °C for 2 h to obtain a carbon dioxide absorbent.

[0039] Compared with the existing method for preparing acetylene by using calcium carbide, the yield of acetylene prepared by the method of the...

Embodiment 2

[0044] The method for synchronously obtaining a carbon dioxide absorbent with the production of acetylene described in this embodiment specifically includes the following steps:

[0045] (1) Add alumina, calcium carbide, and water into the reactor at the same time, wherein the mass ratio of alumina to calcium carbide is 15:100, and the mass ratio of water to calcium carbide is 1000:100. After fully reacting, a mixture of calcium carbide slag slurry is obtained ;

[0046] (2) Dehydrate the mixture of carbide slag slurry obtained in step (1), and then dry it at a constant temperature of 110 °C for 12 hours to obtain solid carbide slag;

[0047] (3) The solid carbide slag obtained in step (2) was calcined in a muffle furnace at a constant temperature of 900 °C for 1 h to obtain a carbon dioxide absorbent.

[0048] Compared with the existing method for preparing acetylene by using calcium carbide, the yield of acetylene prepared by the method of the invention is increased by 6.28...

Embodiment 3

[0053] The method for synchronously obtaining a carbon dioxide absorbent with the production of acetylene described in this embodiment specifically includes the following steps:

[0054] (1) Add aluminum hydroxide, calcium carbide, and water into the reactor at the same time, wherein the mass ratio of aluminum hydroxide to calcium carbide is 20:100, and the mass ratio of water to calcium carbide is 350:100. After fully reacting, calcium carbide slurry is obtained mixture;

[0055] (2) Dehydrate the calcium carbide slag slurry mixture obtained in step (1), and then dry it at a constant temperature at 102 °C for 14 hours to obtain solid carbide slag;

[0056] (3) The solid carbide slag obtained in step (2) was calcined in a muffle furnace at a constant temperature of 860 °C for 1.2 h to obtain a carbon dioxide absorbent.

[0057] Compared with the existing method for preparing acetylene by using calcium carbide, the yield of acetylene prepared by the method of the invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com