A fully automatic sewing thread precision stretching and setting winder and its use method

A sewing thread and winding machine technology, applied in the field of spinning, can solve problems such as uneven heating, uneven stretching, and easy breakage, and achieve uniform winding density, increase production efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

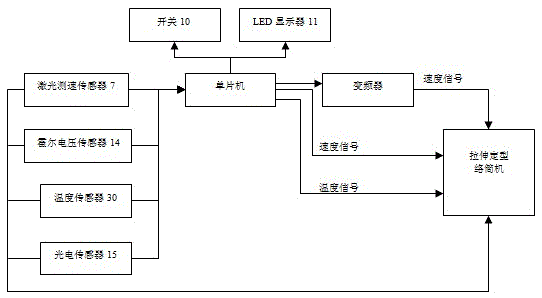

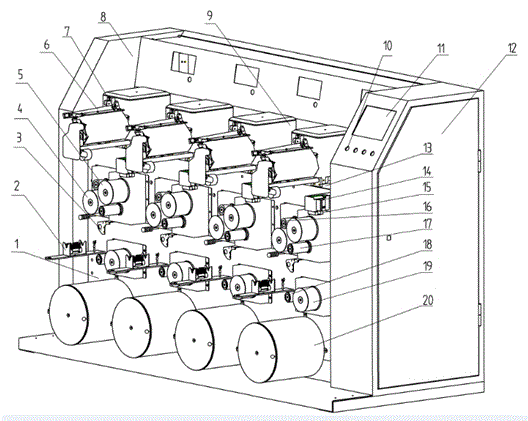

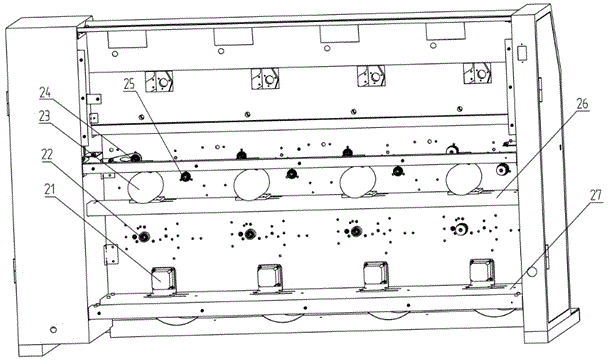

[0021] Such as Figure 1~4 As shown, the fully automatic sewing thread precision stretching and shaping winder includes a single-chip microcomputer, a switch 10, an LED display 11, a laser speed sensor 7, a Hall voltage sensor 14, a temperature sensor 30, a photoelectric sensor 15, a frequency converter, and a stretching and shaping network. Cone machine; stretch setting winder includes stretch setting plate 1, comb-shaped tension grid 2, buffer 3, first roller wheel 4, second roller wheel 5, friction roller 6, machine head device 9, left control box 8. Right control box 12, gear box seat plate 13, first splitting roller 16, second splitting roller 17, hot wheel splitting roller 18, hot wheel 19, yarn holding tube 20, motor upper beam 26, motor lower Beam 27, first roller shaft 25, second roller shaft 24, heat wheel shaft 22, machine head winding motor 23, DC motor 21, heat insulation sleeve 28, heating wire 29; comb-shaped tension grid 2 is installed on the stretch setting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com