Composite sieve plate hole processing multi-spindle CNC drilling and milling platform

A sieve plate hole and multi-spindle technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of stamping and laser processing, such as difficulty, high efficiency, high quality, and low processing efficiency, and achieve efficient processing , large size and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

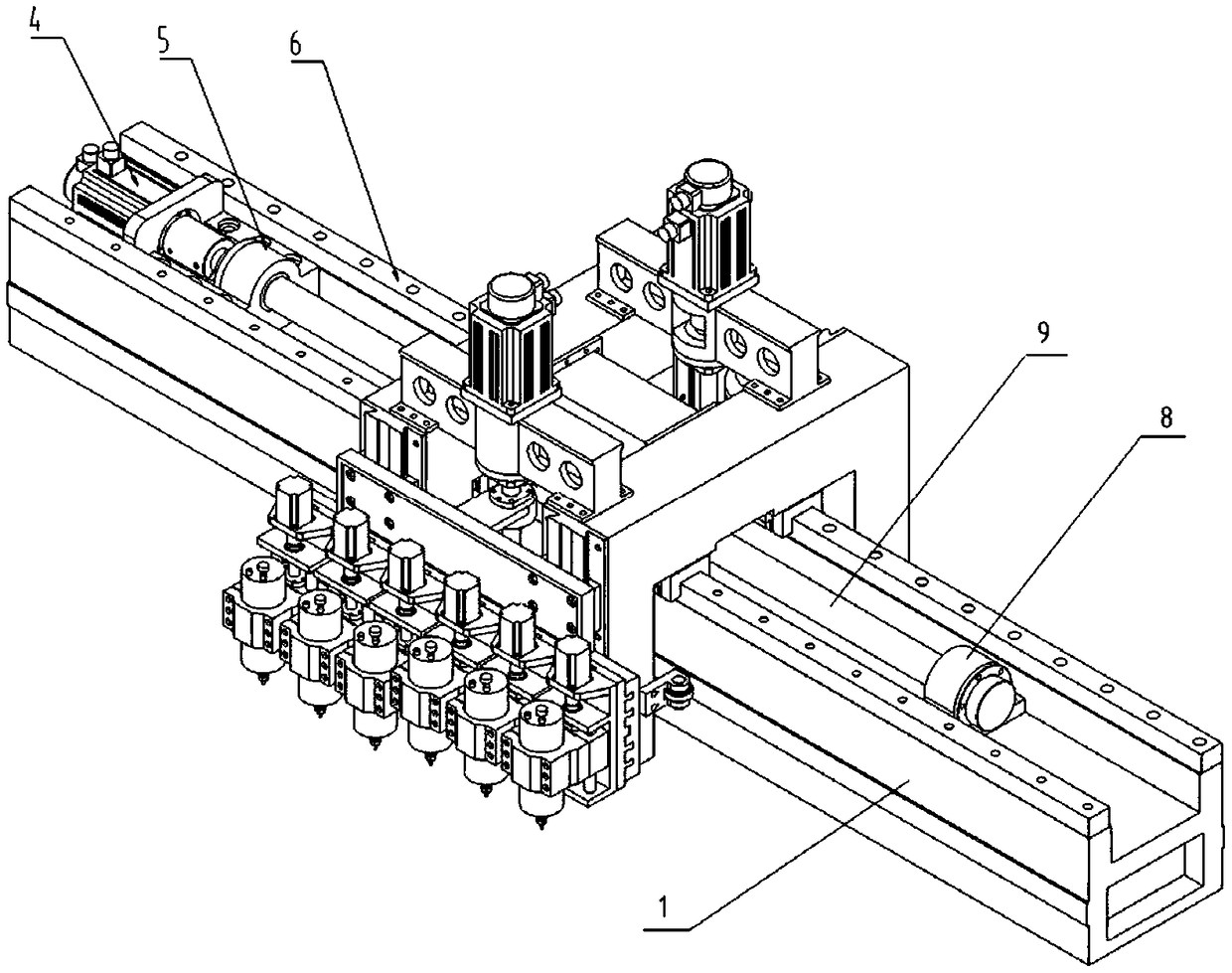

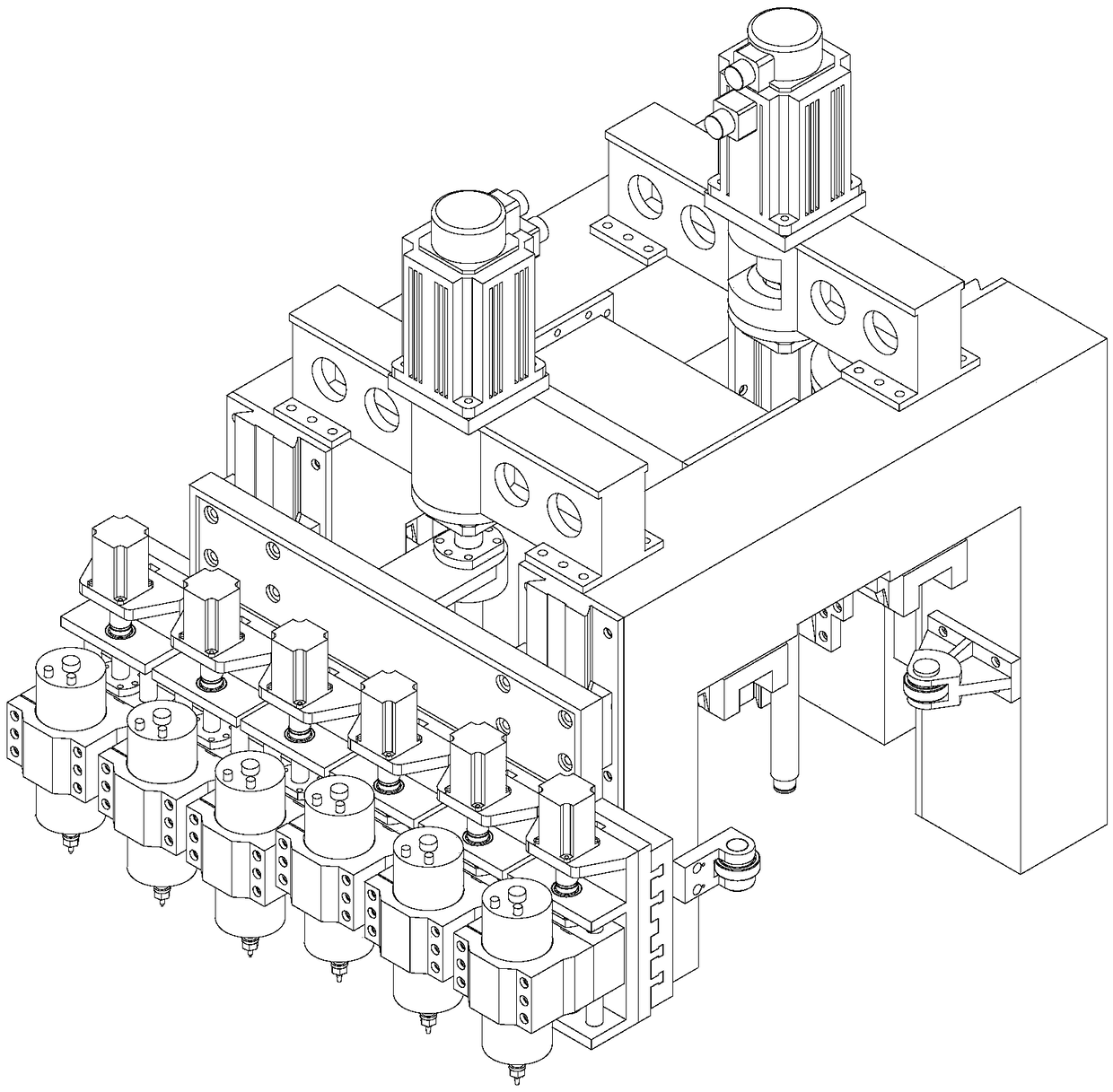

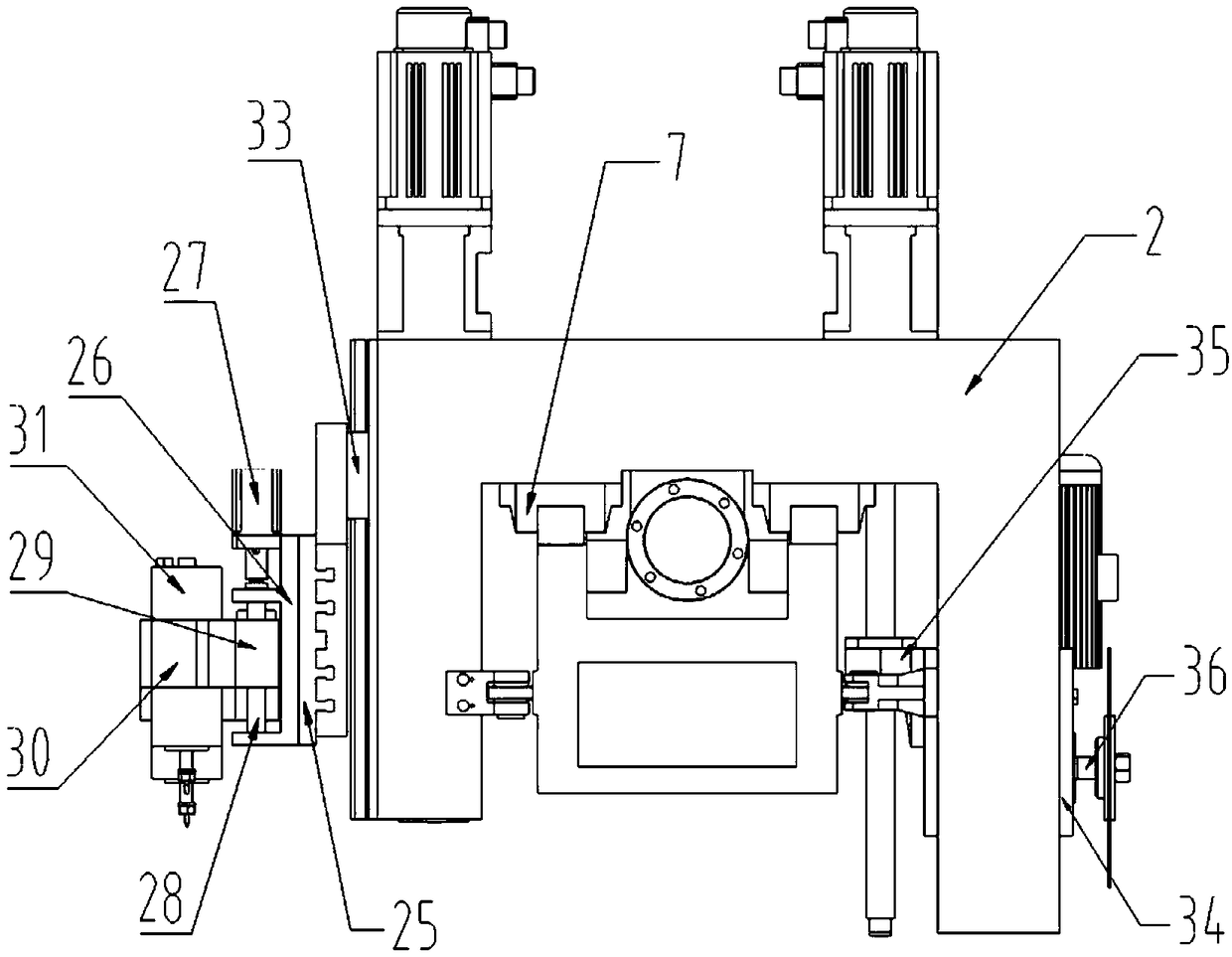

[0019] exist Figure 1-6 In the shown embodiment: including the main beam (1), the longitudinal beam (2), the vertical drilling spindle moving table (3), the horizontal milling spindle moving table (21), the table moving drive device, the longitudinal beam moving drive device, vertical drilling spindle moving workbench lifting drive device, horizontal milling spindle moving workbench lifting drive device, electric spindle lifting drive device, wherein a connecting frame (10) and a longitudinal beam moving drive device are installed between two longitudinal beams (2) Installed on the main beam (1), the vertical drilling spindle moving table lifting drive device and the horizontal milling spindle moving table lifting driving device are respectively installed on both ends of the longitudinal beam (2), and the electric spindle lifting drive device is installed on the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com