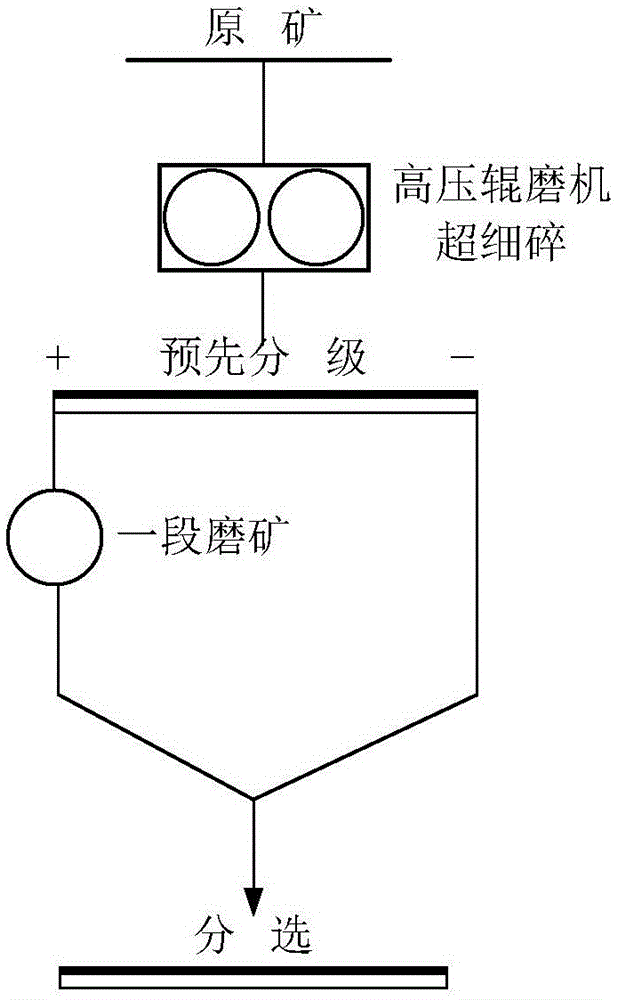

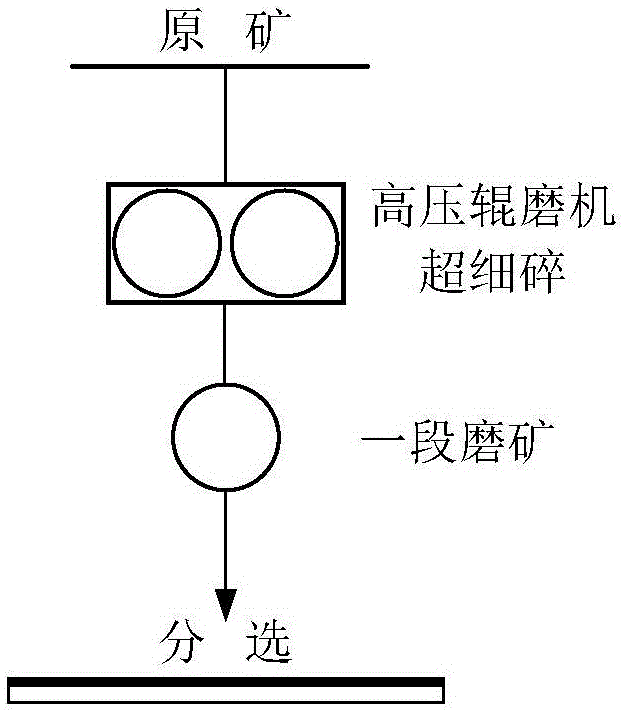

A high-efficiency and low-consumption ultra-fine crushing-grinding process

An ultra-fine crushing and process technology, which is applied in agricultural machinery and equipment, grain processing, energy saving measures, etc., can solve the problems of reducing concentrate grade and recovery rate, increasing power consumption and steel consumption, and increasing beneficiation cost, so as to reduce the beneficiation cost. , the effect of reducing the amount of ore and improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

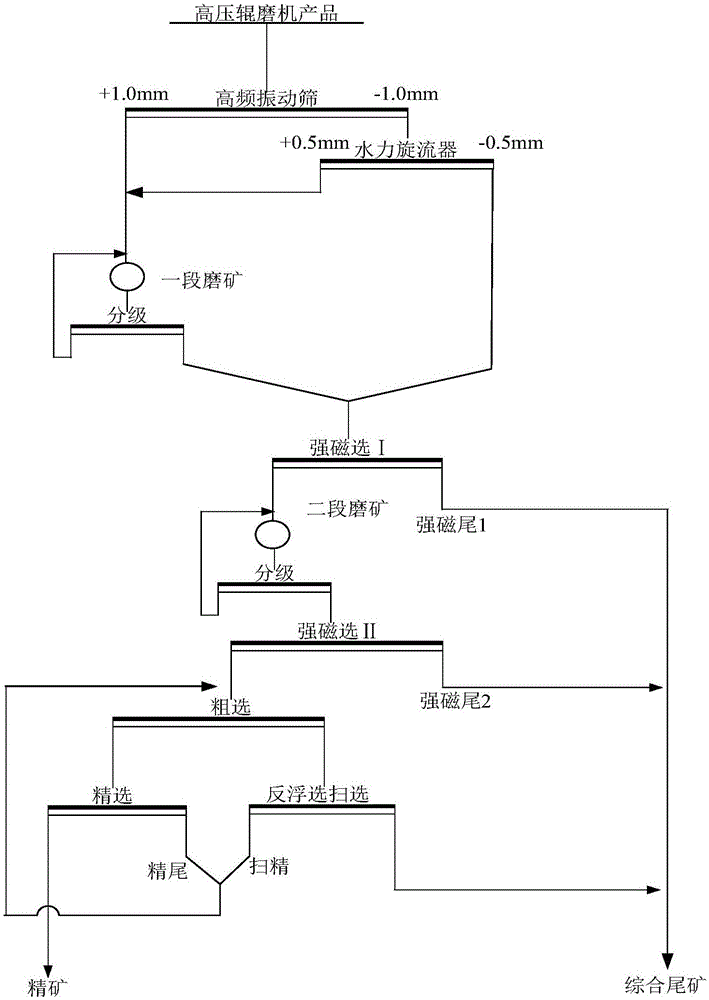

[0019] The crushed ore is an Anshan type lean hematite, with a water content of 3%, a TFe grade of 24.48%, SiO 2 The content is 65.08%. The content of harmful elements S and P is relatively small, and the high-pressure roller mill is used for full-closed ultra-fine crushing. The size of the sieve hole is controlled to 3.2mm, the roller surface pressure is 6MPa during work, the roller speed is 1.6m / min, and the roller gap is 30mm.

[0020] After the lean hematite is ultra-finely crushed by the high-pressure roller mill, it first enters the high-frequency vibrating screen for classification. The graded products with a particle size of +1.0mm directly enter the first stage of grinding, and the classified products with a particle size of -1.0mm enter the hydrocyclone. Classification is carried out by hydrocyclones, and the graded products with a particle size of +0.5mm enter the first stage of grinding after hydrocyclone classification. After hydrocyclone classification -0.5mm pa...

Embodiment 2

[0030] The crushed ore is a molybdenum ore, the ore molybdenum grade is 0.097%, and the molybdenum oxidation rate is 3.4%. The metal minerals are mainly pyrite, molybdenite, chalcopyrite, etc. The gangue minerals are mainly quartz, biotite and feldspar. The high-pressure roller mill performs full-closed ultra-fine crushing, the size of the control screen hole is 3.2mm, the pressure of the roller surface is 5MPa during operation, the roller speed is 1.8m / min, and the roller gap is 25.5mm.

[0031] The molybdenum ore is subjected to full-closed ultra-fine crushing through a high-pressure roller mill. The ultra-fine crushed products first enter the high-frequency vibrating screen for classification, and the classified products with a particle size of +1.0mm directly enter the first stage of grinding, and the classified products with a particle size of -1.0mm are then Enter the hydrocyclone for classification. After classification by the hydrocyclone, the graded products with a par...

Embodiment 3

[0037]The crushed ore is a copper-molybdenum ore in Mongolia. The copper grade of the raw ore is 0.0739%, and the copper oxidation rate is 6.88%; the molybdenum grade is 0.0407%, and the molybdenum oxidation rate is 4.91%. Stone minerals are mainly quartz, potassium feldspar, plagioclase, mica, etc., using a high-pressure roller mill for full-closed ultra-fine crushing, controlling the size of the sieve hole to 3.2mm, the pressure on the roller surface during work is 4MPa, and the roller speed is 1.8m / min, the roll gap is 25mm.

[0038] The copper-molybdenum ore is subjected to full-closed ultra-fine crushing through a high-pressure roller mill. The ultra-fine crushed products first enter the high-frequency vibrating screen for classification, and the classified products with a particle size of +1.0mm directly enter the first stage of grinding, and the classified products with a particle size of -1.0mm Then enter the hydrocyclone for grading. After grading by the hydrocyclone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com