A kind of clarified sugar-free tartary buckwheat tea and its production method

The technology of a sugar tartary buckwheat tea and a production method, which is applied in the field of food processing, can solve the problems of patent literature and non-patent literature reports of liquid tartary buckwheat tea, etc., and achieve the effects of being beneficial to clarification, prolonging the shelf life and reducing the problem of precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

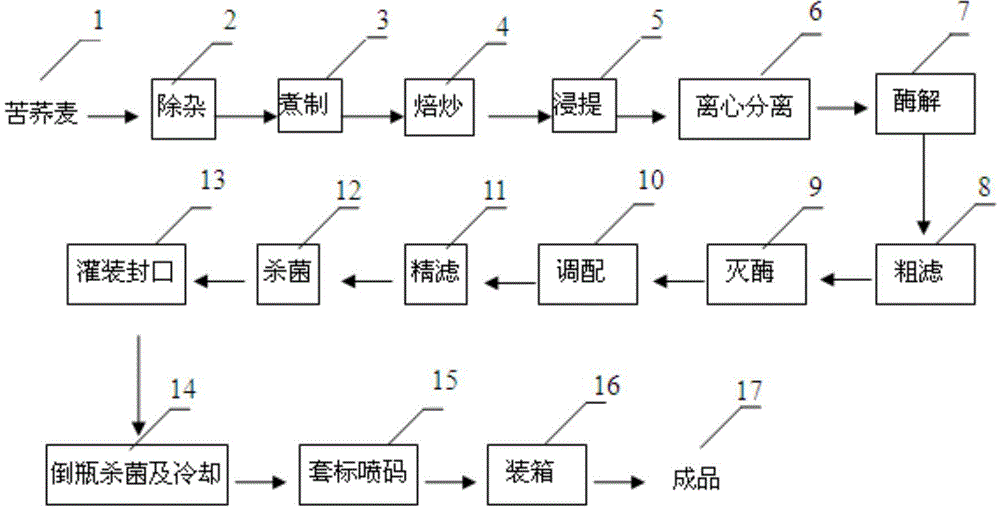

[0054] The tartary buckwheat with skin of good quality is removed from the impurities by winnowing machine, vibrating screen, specific gravity sorting machine and magnetic sorting machine; put the tartary buckwheat in boiling water and cook for 5 minutes, remove and drain; add the clean sand into the frying pan Or heat the temperature to 200°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 20 minutes; sieve and separate to obtain roasted tartary buckwheat; Ratio, Stir and extract at a temperature of 93°C for 30 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.1 part of α-amylase to 1000 parts of the centrifuge, Insulate and stir for 40 minutes for enzymolysis; use a bag filter to remove the precipitate in the enzymolysis tartary buckwheat liquid, the filter bag has a pore size of 0.8 μm; pump the coarsely filtered tartary buckwheat liquid int...

Embodiment 2

[0056] The tartary buckwheat with skin of good quality is removed from the impurities by winnowing machine, vibrating screen, specific gravity sorting machine and magnetic sorting machine; put tartary buckwheat in boiling water and cook for 10 minutes, remove and drain; add clean sand into the frying pan Or heat up to 230°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 10 minutes; sieve and separate to obtain roasted tartary buckwheat; add roasted tartary buckwheat into the extraction tank, and use a material-to-liquid ratio of 1:50 Stir and extract at a temperature of 98°C for 20 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.05 parts of α-amylase to 1000 parts of the centrifuge, and keep stirring at a temperature of 55°C Enzymatic hydrolysis for 80 minutes; use bag filter to remove the precipitate in the enzymatic tartary buckwheat solut...

Embodiment 3

[0058] The tartary buckwheat with skin of good quality is removed from the impurities by winnowing machine, vibrating sieve, specific gravity separator and magnetic separator; put tartary buckwheat in boiling water and cook for 9 minutes, remove and drain; add clean sand into the frying pan Or heat the temperature to 220°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 13 minutes; sieve and separate to obtain roasted tartary buckwheat; Ratio, temperature 96°C stirring and leaching for 23 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.075 parts of α-amylase to 1000 parts of the centrifuge, and keep warm at a temperature of 58°C Stir the enzymatic hydrolysis for 60 minutes; use the bag filter to remove the precipitate in the enzymatic tartary buckwheat liquid; the pore size of the filter bag is 2 μm; pump the coarsely filtered tartary buckwhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com