Removable water-dispersible acrylic-based adhesive composition and adhesive sheet

An acrylic, dispersion-type technology, applied in the direction of acidic copolymer adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of easy pollution, achieve low pollution, excellent re-peeling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

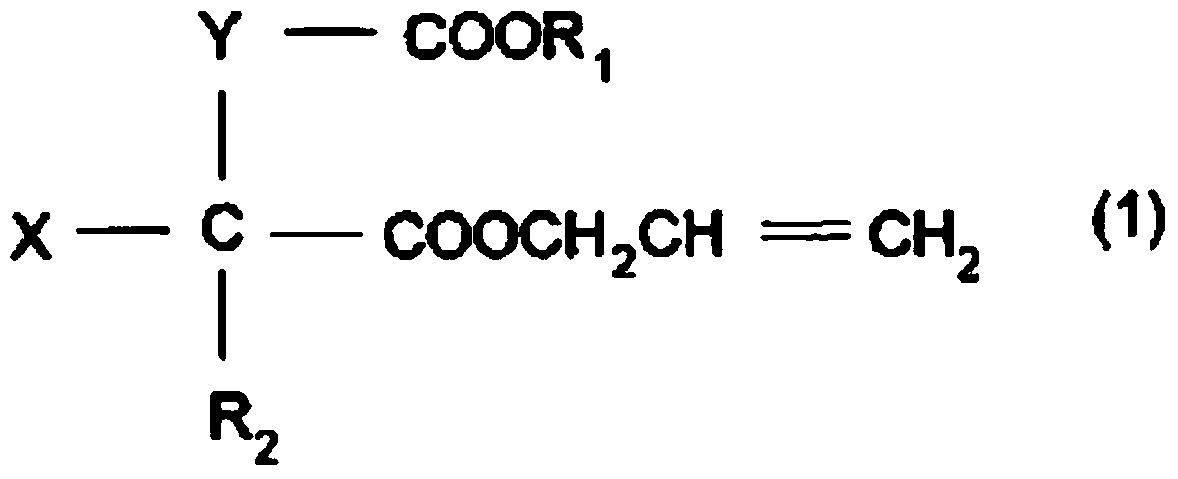

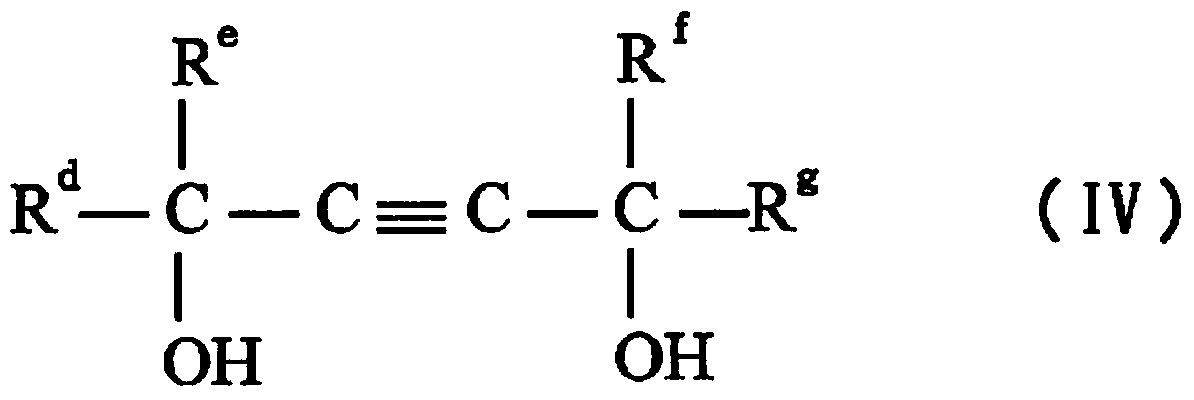

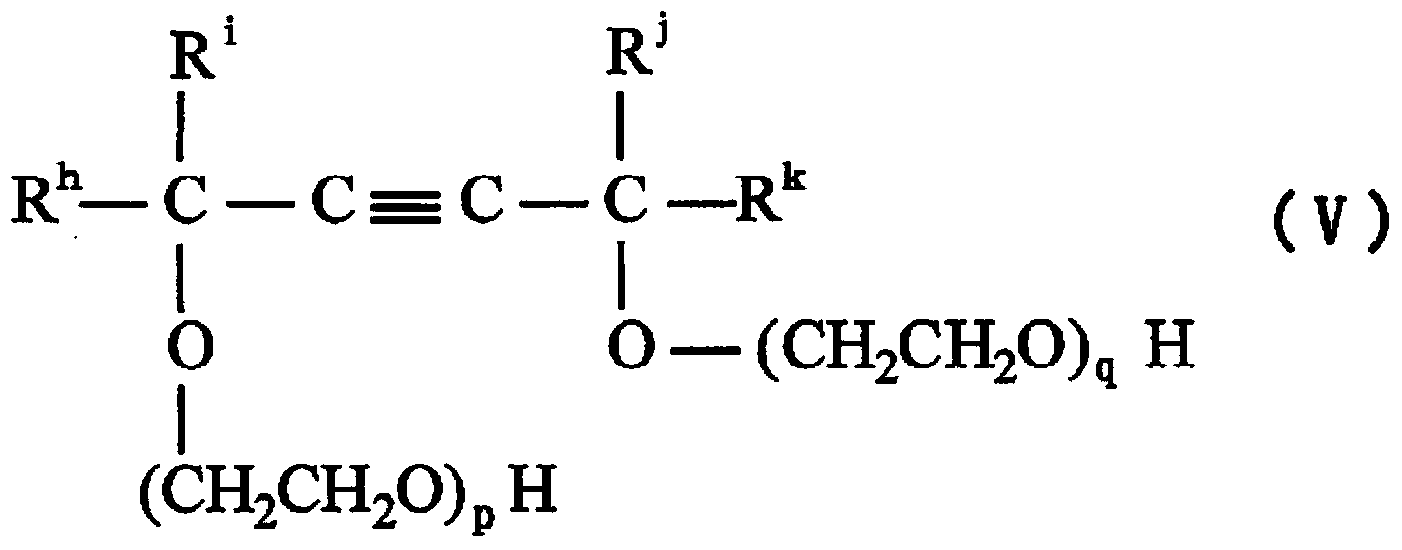

Method used

Image

Examples

Embodiment 1

[0223] (Preparation of Acrylic Emulsion Polymer (A))

[0224] Mix 90 parts by weight of water and raw material monomers and reactive surfactants (reactive surfactants that do not contain oxyalkylene groups) in the amount shown in Table 1 in the container, then stir and mix with a high-speed mixer, Prepare a monomer emulsion.

[0225] Then, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and 10 wt. amount, emulsion polymerization was carried out at 75° C. for 1 hour while stirring. Then, 0.07 parts by weight of a polymerization initiator (ammonium persulfate) was further added, and the remaining whole monomer emulsion (an amount corresponding to 90% by weight) was added over 3 hours while stirring, and reacted at 75° C. for 3 hours. Then, it was cooled to 30° C., and adjusted to pH 8 by adding ammonia water at a concentration of 10% by weight to prepare an aqueous dispersion of an acrylic emulsion polymer (concentration of ...

Embodiment 2~20、 comparative example 1~8

[0231] As shown in Tables 1, 2, and 3, by changing the type and compounding amount of the raw material monomers, reactive surfactants, and the compounding amount of the surfactant (D), the re-peeling water-dispersible acrylic acid was obtained in the same manner as in Example 1. Adhesive-like composition and adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com