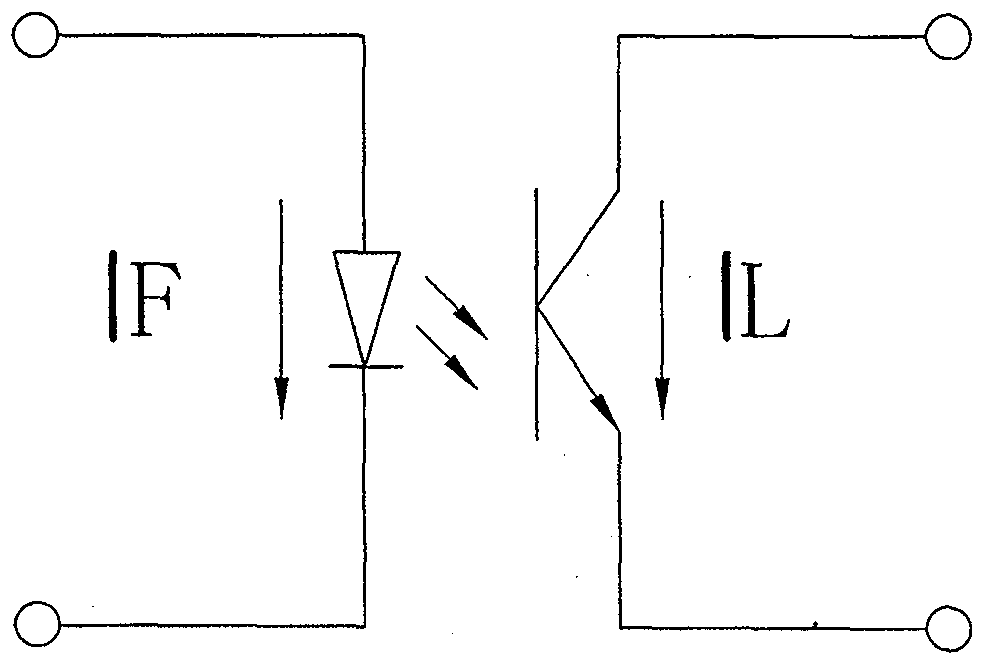

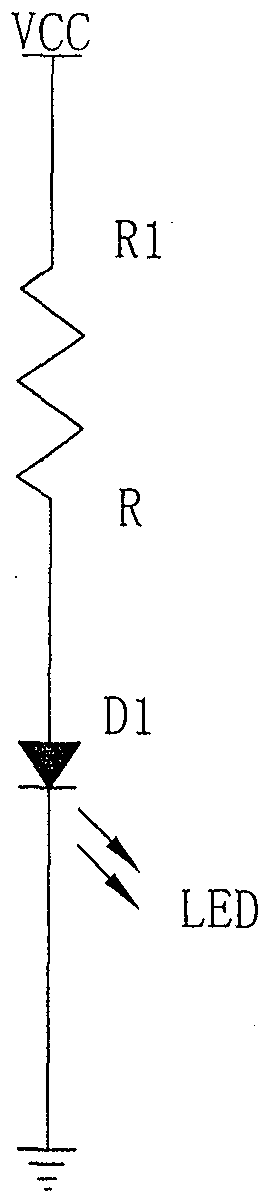

A transmitter drive circuit for a photoelectric sensor

A photoelectric sensor and drive circuit technology, applied in the direction of electric lamp circuit layout, light source, electric light source, etc., can solve the problems of sensor pollution, LED current change, luminous brightness instability, etc., and achieve the effect of improving work stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

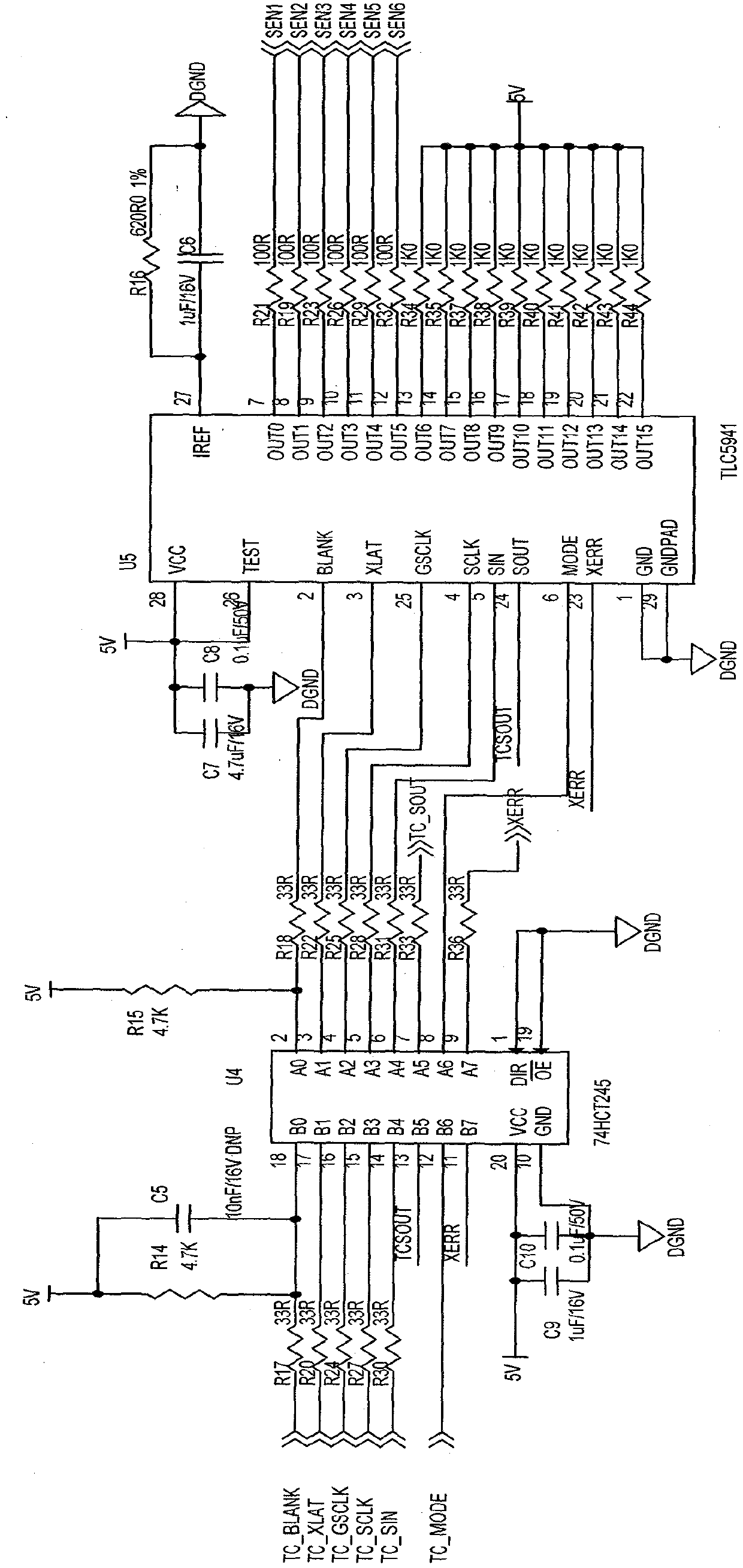

[0018] Examples, see image 3 . The transmitter drive circuit of the photoelectric sensor of this embodiment includes:

[0019] One LED driver chip TLC5941 U5 and one signal driver chip 74HCT245 U4; among them,

[0020] Connect a matching resistor R17, R20, R24, R27 and R30 to the signal line of the input pin B0-B4 of the signal driver chip 74HCT245 U4, and connect a pull-up resistor R14 and R14 between the resistor R17 and the input pin B0 Capacitor C5 and the other end of resistor R17 are connected to the 5V power supply; the output pins A0-A4 of the signal driver chip 74HCT245 U4 are respectively connected to the input pins BLANK, XLAT, GSCLK, SCLK and SIN of the LED driver chip TLC5941 U5. A matching resistor R18, R22, R25, R28 and R31 are respectively connected in series in the connection signal line, and a pull-up resistor R15 is also connected in parallel between the output pin A0 and the resistor R18, and the other end of the pull-up resistor R15 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com