Method for improving film formation uniformity of wafer

A uniformity and process technology, which is applied in the field of improving the film formation uniformity of process sheets in semiconductor vertical furnace equipment, can solve the problems of poor film formation uniformity, uneven temperature field and air flow field, etc., and achieves improved film formation uniformity, The effect of reducing production costs and optimizing film uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

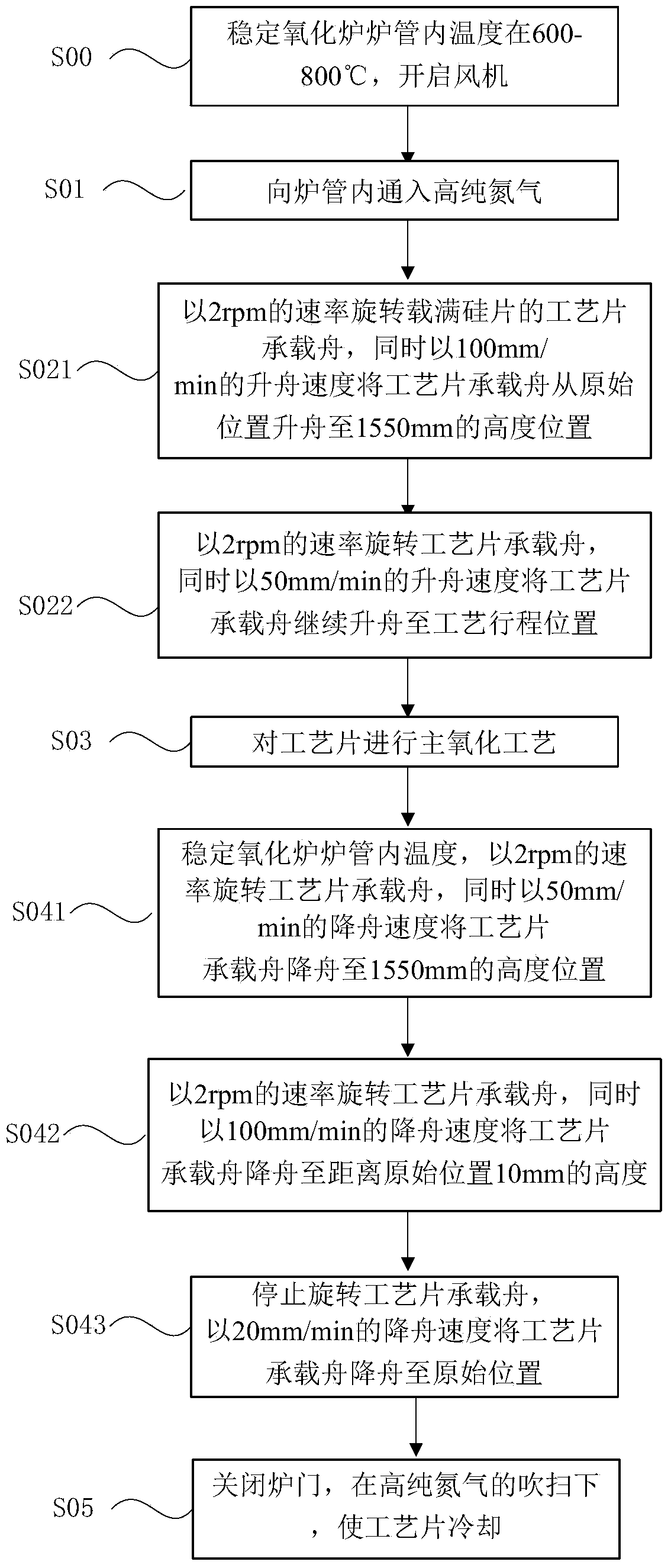

[0029] The method that the present invention improves the film-forming uniformity of process sheet, it comprises:

[0030] Step S01, introducing nitrogen gas into the hot oxidation furnace tube, and purging the inside of the furnace tube with nitrogen gas to create an environment;

[0031] Step S02, rotating the process chip carrier boat in the furnace tube at a low speed, and raising the boat from the original position to the process stroke position;

[0032] Step S03, keep rotating the craft sheet carrying boat, and perform the main oxidation process on the craft sheet;

[0033] Step S04, after the main oxidation process is completed, keep rotating the process sheet carrying boat, and lower the boat from the process stroke position to the original position.

[0034] The process chip carrier boat of the present invention is placed on the heat preservation barrel, and the heat preservation barrel is set on the quartz plate, and the rotating shaft passes through the process ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com