Metal electrode, touch electrode layer, color film substrate and display panel

A metal electrode, color filter substrate technology, applied in the field of communication, can solve the problems of difficult touch detection, signal deformation, process temperature limitation, etc., to achieve the effect of improving clarity and accuracy, avoiding moiré fringes, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

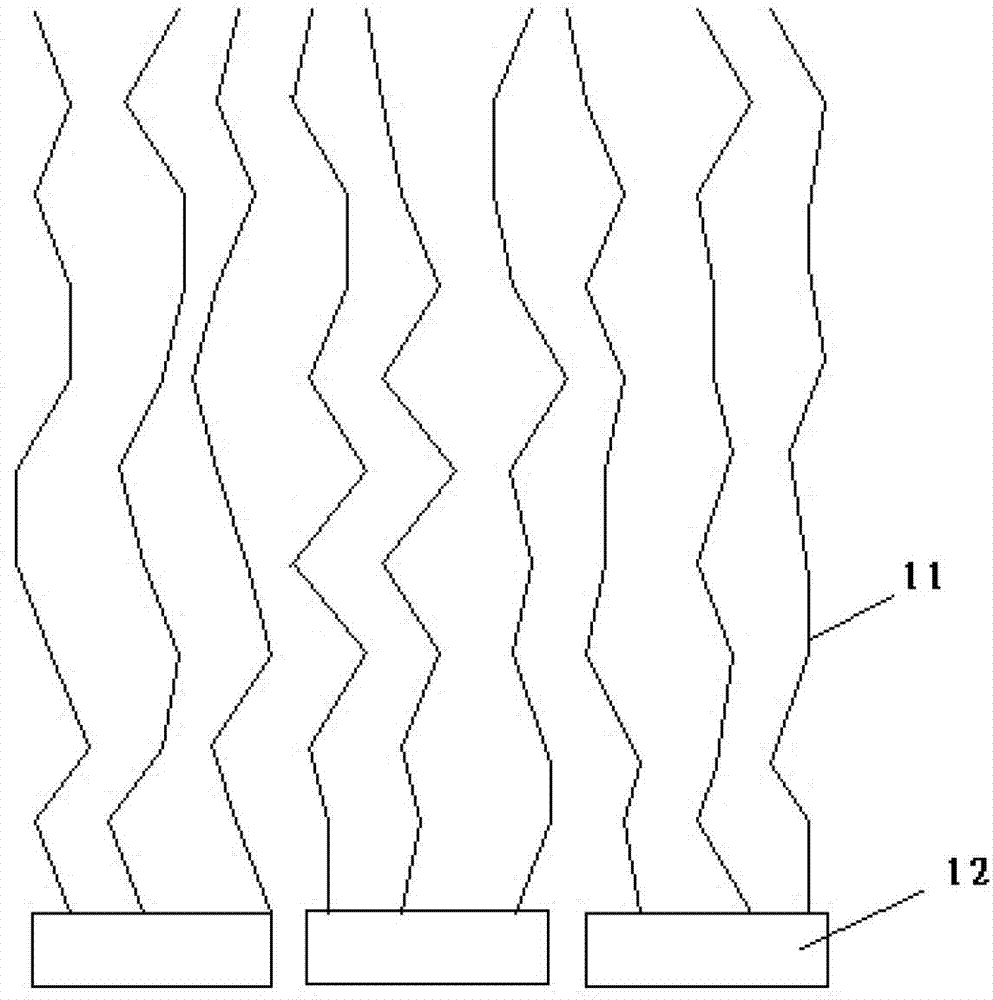

[0041] Embodiment 1 of the present invention provides a metal electrode, and the structure of the metal electrode can be as follows figure 2 As shown, a plurality of strip-shaped sub-electrodes 11 are included, and the strip-shaped sub-electrodes 11 have random shapes. The random shape here means that from a macroscopic point of view, the strip-shaped sub-electrodes 11 extend in the same direction. During the extension process, the strip-shaped sub-electrodes 11 bend left and right in the horizontal direction. The degrees and directions of bending of other strip-shaped sub-electrodes 11 are the same or different, and there is no uniform law of bending and extending macroscopically, so the strip-shaped sub-electrodes 11 appear as random shapes macroscopically.

[0042] It should be noted that the strip shape mentioned here means that each sub-electrode 11 extends in the same direction from a macroscopic point of view, and is generally strip-shaped, and does not mean that the p...

Embodiment 2

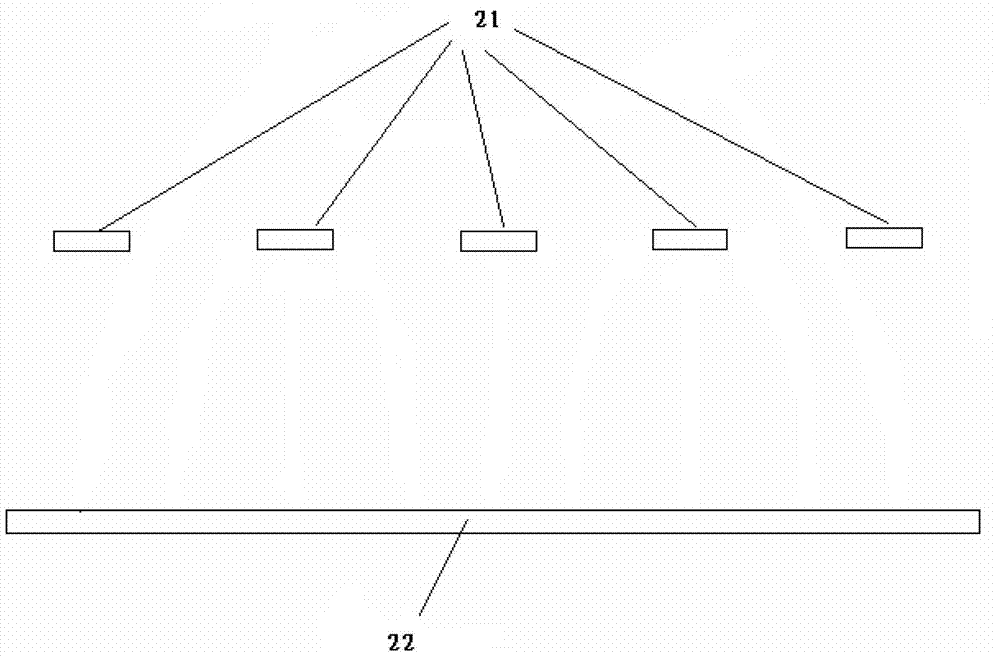

[0055] Embodiment 2 of the present invention provides a touch electrode layer. The touch electrode layer includes sensing electrodes 21 and drive electrodes 22 formed of metal electrodes provided in Embodiment 1 of the present invention, such as image 3 As shown, it is a side view of the touch electrode layer, wherein the sensing electrode 21 includes a plurality of strip-shaped sub-electrodes, and each of the strip-shaped sub-electrodes has a random shape.

[0056] Specifically, the driving electrodes 22 may be made of indium tin oxide or indium zinc oxide. And the driving electrodes 22 and the sensing electrodes 21 are vertically arranged, that is, each driving electrode 22 is perpendicular to each sensing electrode 21 .

[0057] In the touch electrode layer provided by the second embodiment of the present invention, under the condition that the resistance of the sensing electrode 21 is sufficiently small, since the width of each strip-shaped sub-electrode in the sensing el...

Embodiment 3

[0062] Embodiment 3 of the present invention provides a color filter substrate, such as Figure 5 As shown, the color filter substrate may include a transparent substrate 52 and a touch electrode layer as provided in the second embodiment. The touch electrode layer includes sensing electrodes and driving electrodes, wherein the sensing electrodes include a plurality of strip-shaped sub-electrodes, and each of the strip-shaped sub-electrodes has a random shape. In this embodiment, the sensing electrodes and the driving electrodes are respectively located on two sides of the transparent substrate 52 .

[0063] Further preferably, the sensing electrodes of the touch electrode layer may include a plurality of strip-shaped sub-electrodes 51 , and a plurality of first parts 53 for connecting part of the strip-shaped sub-electrodes 51 . And in another embodiment, all the first parts 53 can also be connected to a flexible printed circuit (FPC, Flexible Printed Circuit) 54, so as to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com