A cladding optical power stripping method of a double-clad optical fiber

A technology of double-clad optical fiber and cladding light, which is applied in the field of optoelectronics, can solve the problems of insignificant ASE suppression effect, attenuation of cladding light power, and increase of light divergence angle, so as to improve beam quality, effective absorption and stripping, The effect of increasing the divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

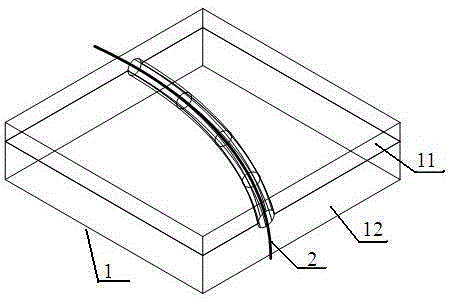

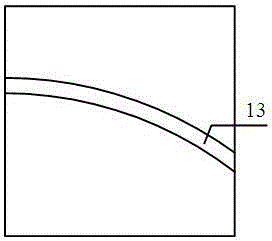

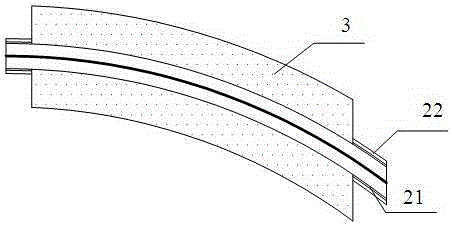

[0022] An all-fiber laser strips off a section of outer cladding and coating layer of the double-clad fiber after the fiber grating at the output end, and the length of the stripped section is 64mm. The core diameter of the double-clad optical fiber 2 involved here is 25 μm, NA~0.06; the inner cladding diameter is 250 μm, NA~0.46, and the diameter of the high-refractive index organic coating is about 2.5 mm, and the refractive index is 1.45. The metal with good thermal conductivity is used to make the above-mentioned mechanical element 1. The size of the substrate is 60mm×60mm×10mm, and a curved semi-cylindrical groove 13 with a diameter slightly less than 2.5mm is milled on its upper surface, the radius of curvature is 100mm, and the length is 50mm. The size of the cover plate 12 of the mechanical element 1 is 60mm×60mm×5mm, and the same groove is also milled on its lower surface. In this way, when the cover plate 12 is combined with the base plate 11, the close contact betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com