Plastic composite pipe of nonmetal framework

A composite pipe, non-metal technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of easy corrosion of steel mesh skeleton, inconvenient maintenance, short service life, etc., and achieve light weight and firm connection. Good quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

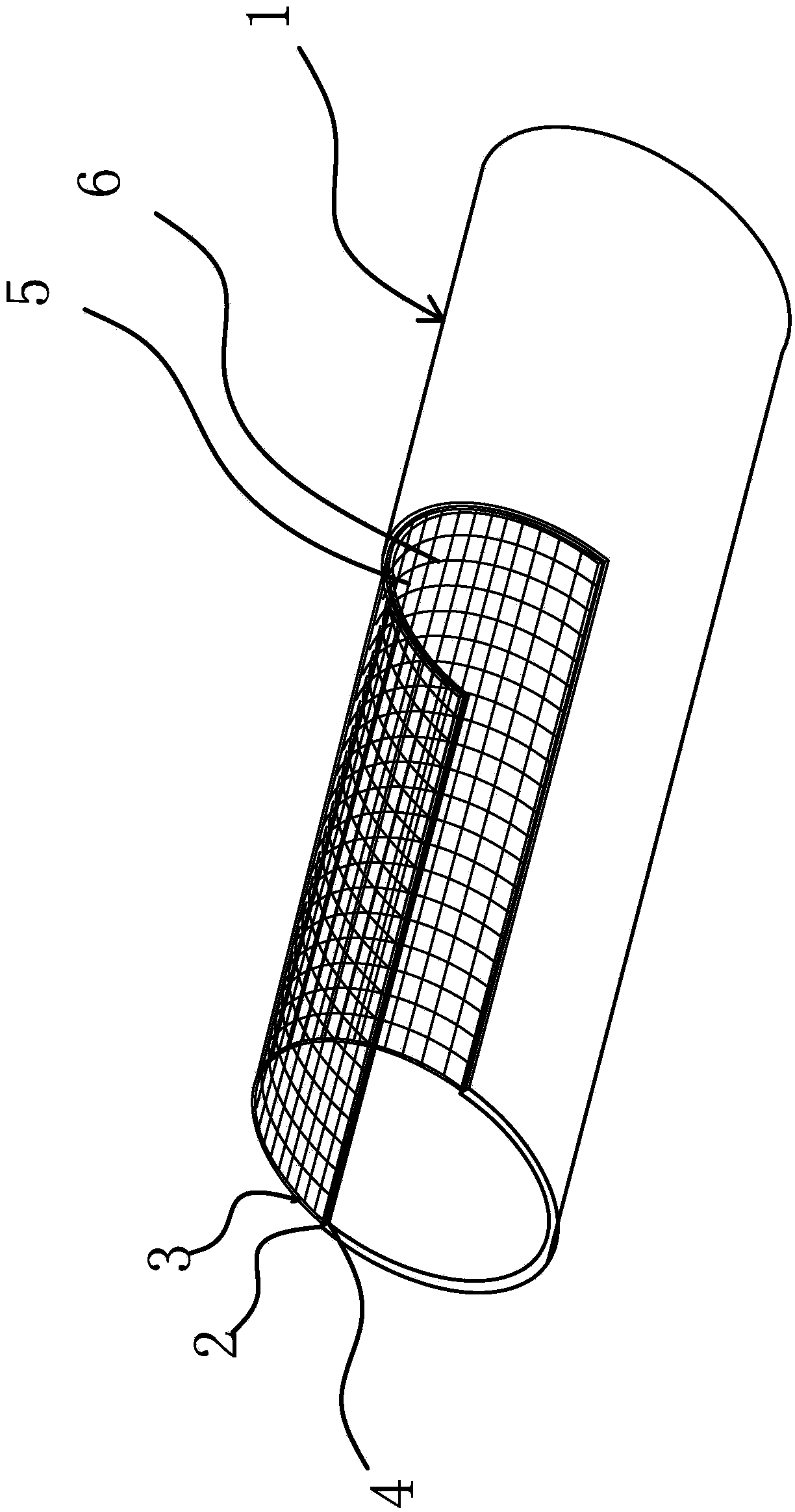

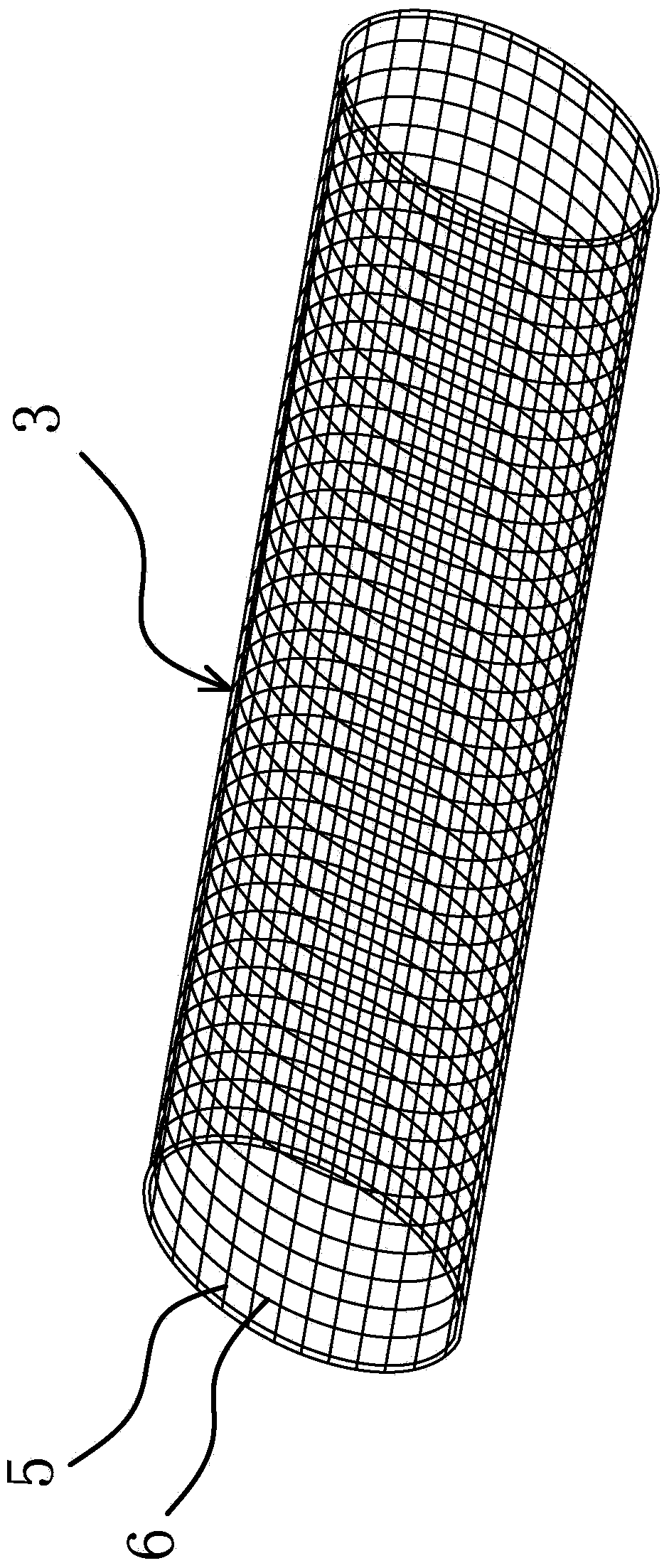

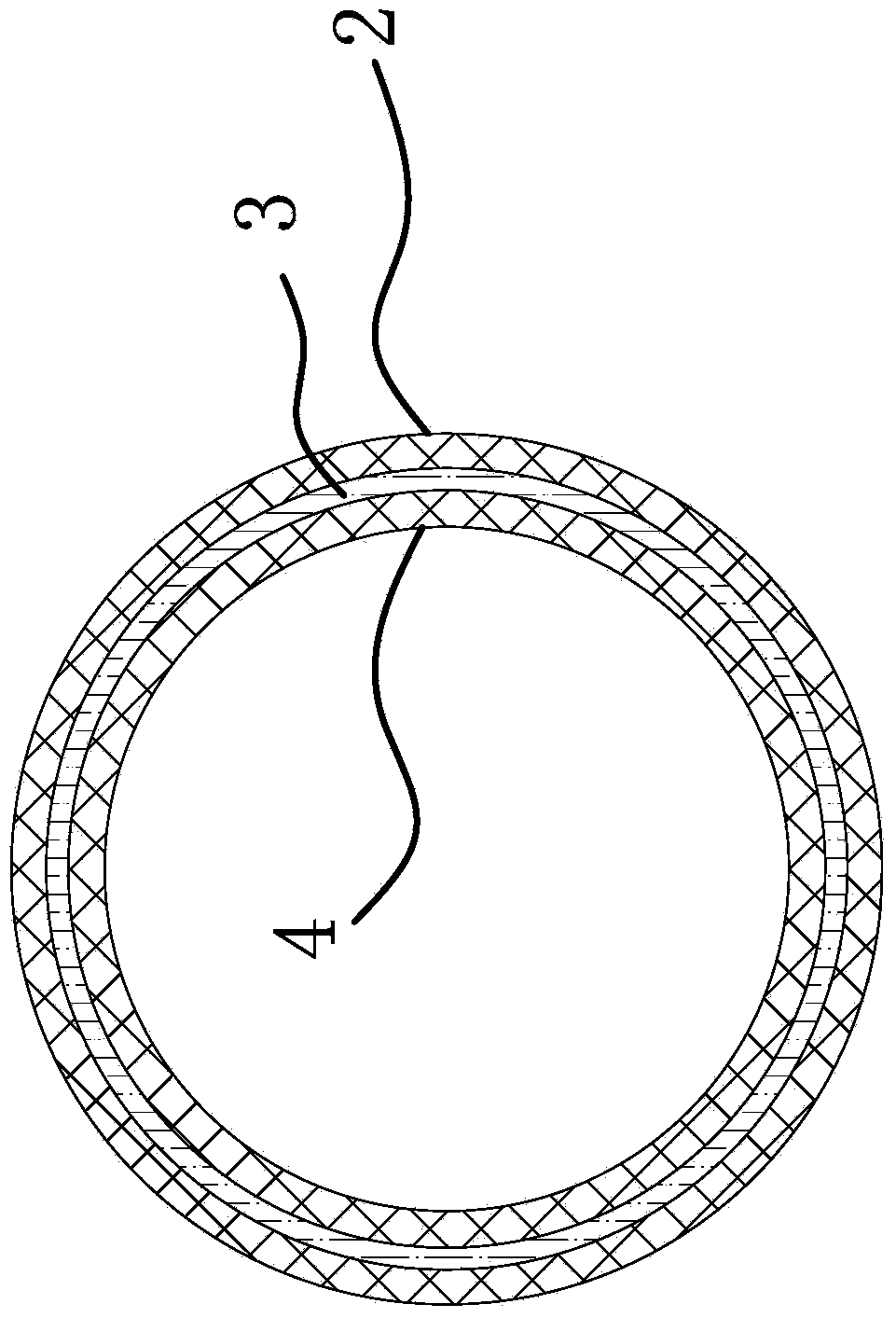

[0024] The composite pipe includes a pipe body 1. The pipe body 1 includes a pipe wall outer layer 2, an annular skeleton 3 and a pipe wall inner layer 4 arranged concentrically and sequentially superimposed. Both the pipe wall outer layer 2 and the pipe wall inner layer 4 are dense. The plastic layer, the ring-shaped skeleton 3 is grid-like, and the ring-shaped skeleton 3 is a non-metallic part that resists compression. As a solution, the non-metallic part is PE material welded with glass fibers, and PE is the matrix. PE is a kind of plastic. After adding glass fiber to it as the matrix, it can be molded by injection molding and has good compression resistance. PE can also be homologous with the plastic of the outer layer 2 of the pipe wall and the inner layer 4 of the pipe wall, and can achieve tightness. Welded and fixed, the firmness of the connection is unexpectedly good. The proportion of glass fiber is 0.6-0.9, preferably 0.8. Within the above specific gravity range, t...

Embodiment 2

[0030] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, as another solution, the number of annular skeletons 3 is two and both are located in the outer layer 2 of the pipe wall and the inner layer 4 of the pipe wall. Among them, the caliber of one of the annular skeletons 3 is smaller than that of the other, the two annular skeletons 3 are concentrically distributed and fixedly connected between the two through a number of reinforcing ribs 7, and the reinforcing ribs 7 are distributed along the radial direction of the pipe body 1, strengthening Both ends of the ribs 7 are fixed on the grid intersection of two ring frames 3, wherein the ring frame 3 with a small diameter is welded and fixed to the inner layer 4 of the pipe wall, and the ring frame 3 with a large diameter is connected to the outer layer of the pipe wall. Layer 2 is fixed by welding. The advantage of setting two overlapping ring frames 3 is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com