High-efficiency and low-noise reciprocating piston refrigerator compressor and its manufacturing process

A refrigerator compressor and reciprocating piston technology, which is applied to liquid variable-capacity machinery, mechanical equipment, variable-capacity pump components, etc., can solve the problems of low energy efficiency ratio, high noise, etc., so as to improve the energy efficiency ratio and reduce noise and noise. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

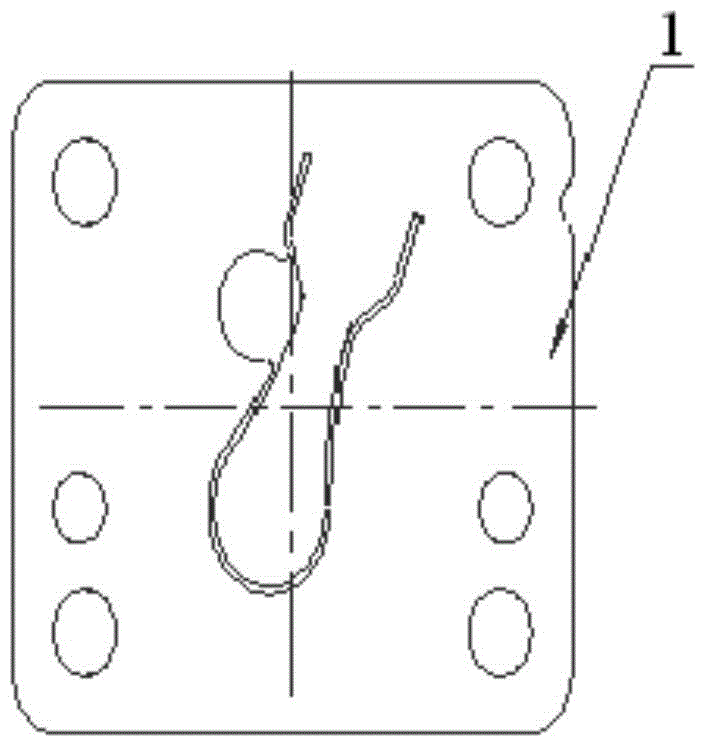

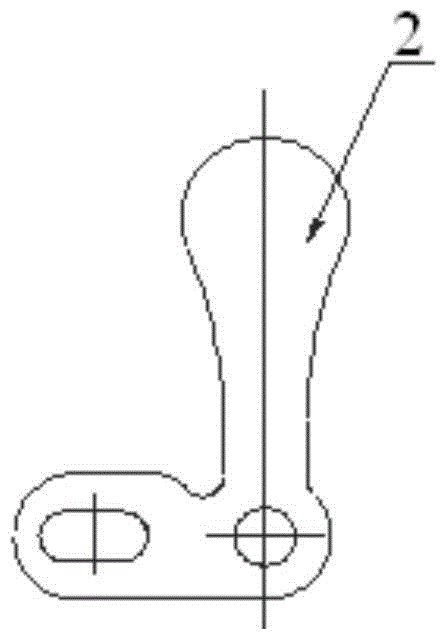

[0061] The surface of one of the two parts of the suction valve plate 1 and the exhaust valve plate 2 is coated with engineering plastics polytetrafluoroethylene or PEEK.

Embodiment 2

[0063] The surfaces of both the suction valve plate 1 and the exhaust valve plate 2 are coated with engineering plastics polytetrafluoroethylene or PEEK.

Embodiment 3

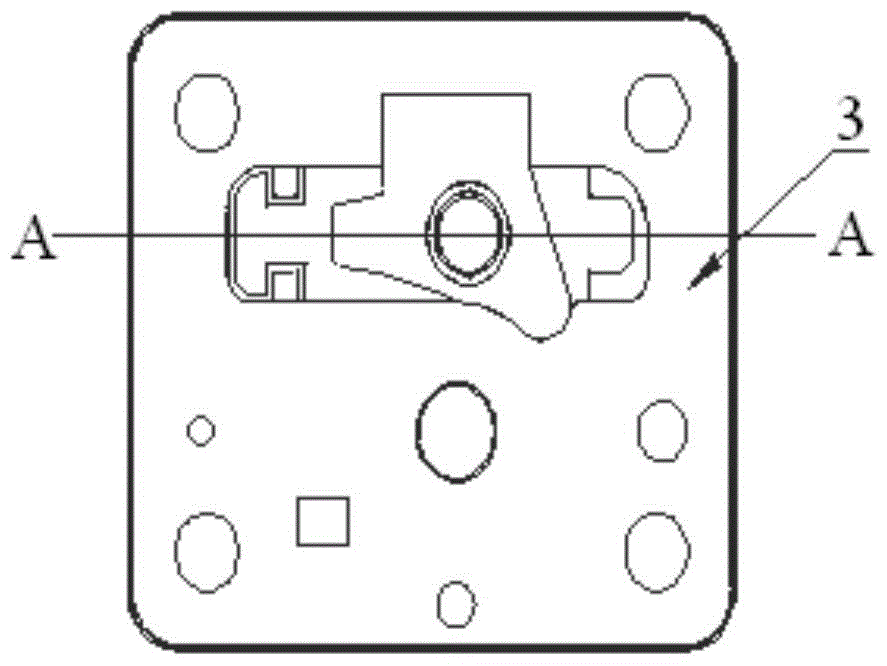

[0065] One of the above-mentioned three parts of the valve plate 3, the suction valve plate 4 and the exhaust valve plate 5 is directly formed by punching PEEK engineering plastics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com