Post-tensioning prestress type self-centering steel frame structure

A post-tensioning, steel frame technology, applied in building components, building structures, earthquake-proof, etc., can solve problems such as tension cracking, uncoordinated lateral deformation of floor and frame, and achieve the effect of avoiding tension cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

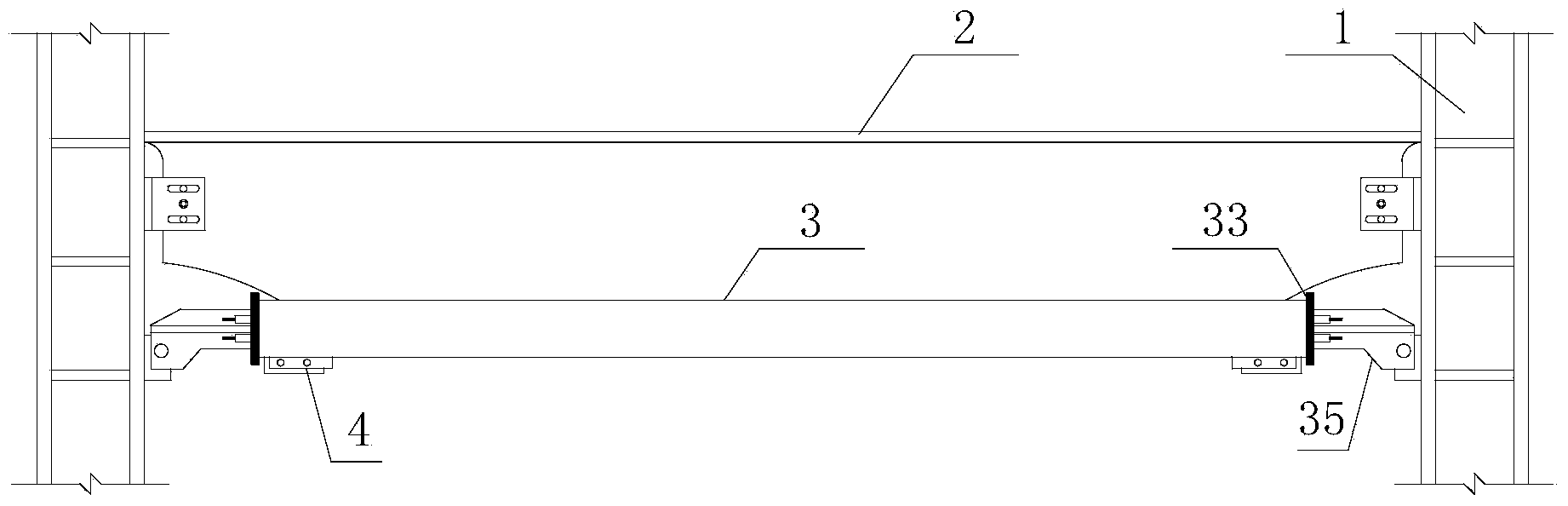

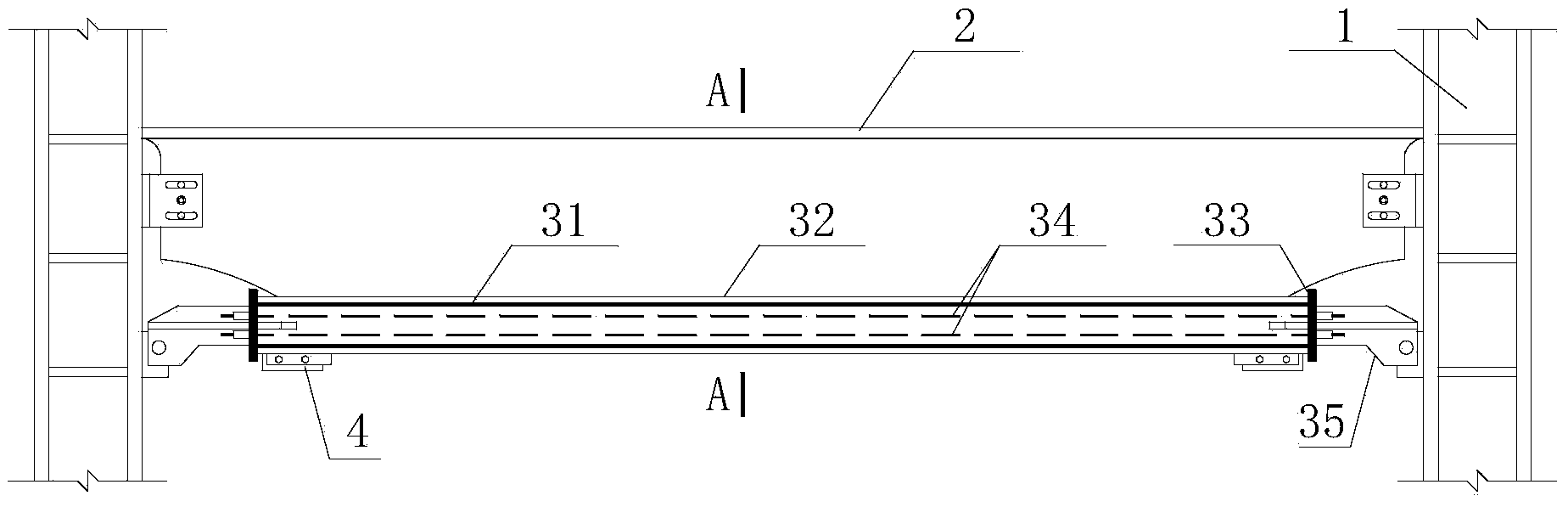

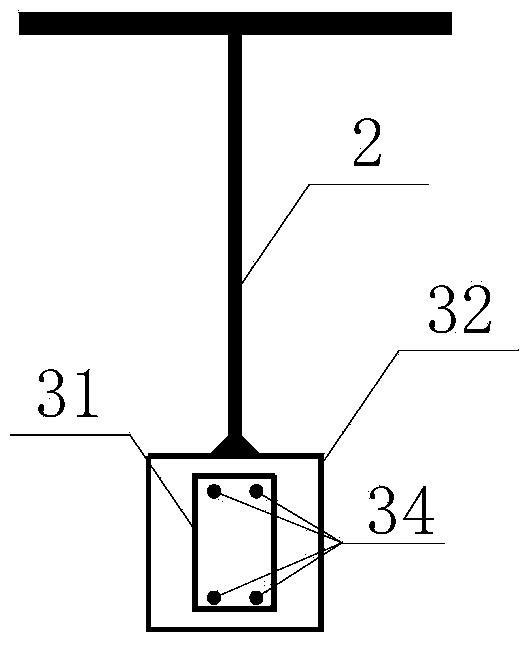

[0036] Such as figure 1As shown, the post-tensioned prestressed self-centering steel frame structure of the present invention includes at least one structural unit, and each structural unit includes two steel frame columns 1, a T-shaped steel beam 2 connecting the upper ends of the two steel frame columns 1, The self-centering connecting piece 3 located on the lower side of the T-shaped steel beam 2 and connecting two steel frame columns 1, the frictional energy-dissipating part 4 located under the self-centering connecting piece 3, wherein the T-shaped steel beam 2 is connected with the self-centering Part 3 and steel frame column 1 are connected by hinges, so as to avoid plastic hinges at the beam-column joints when the structure undergoes lateral deformation; the length of the upper flange of T-shaped steel beam 2 is greater than the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com