Metallographical corrosive liquid and preparation method thereof and 2205 duplex stainless steel metallographical display method

A technology of duplex stainless steel and display method, which is applied in the preparation of test samples, etc., can solve the problems of inability to clearly display austenite and ferrite grains, and achieve a simple and rapid configuration method, clear grain boundaries, and easy effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1 gram of potassium metabisulfite in 50 ml (60°C) hot water first, then add 10 ml of hydrochloric acid with a mass fraction of 36%, and keep stirring with a glass rod to prepare a corrosion solution.

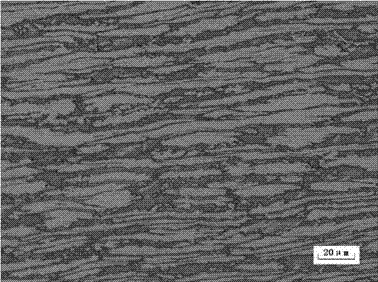

[0021] Operate the No.1 plate of 2205 duplex stainless steel according to the above display method, in which the height of the corrosive solution submerged in the absorbent cotton is 3 mm, and the corrosion time is 20 minutes. Metallographic structure diagram as figure 2 shown.

Embodiment 2

[0023] Dissolve 2 grams of potassium metabisulfite in 50 ml (50°C) hot water first, then add 20 ml of hydrochloric acid with a mass fraction of 36% and keep stirring with a glass rod to prepare a corrosion solution.

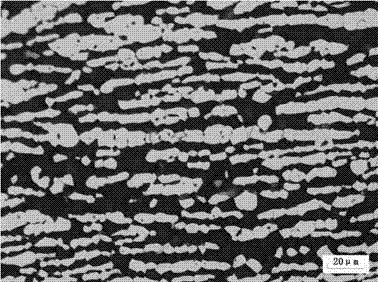

[0024] The 2205 duplex stainless steel slab sample is operated according to the above-mentioned display method, in which the height of the corrosive solution submerged in the absorbent cotton is 5 mm, and the corrosion time is 10 minutes. Metallographic structure diagram as image 3 shown.

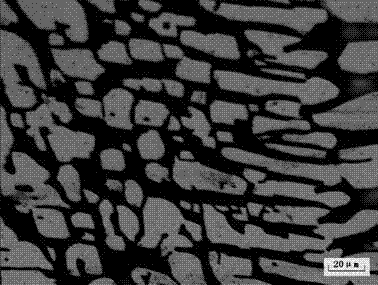

[0025] From the two examples, it can be seen that the austenite and ferrite grains in the metallographic microstructure of the sample are black and white, the display effect is good, and the surface is free from pollution, which shows that the corrosion effect of the corrosive solution on 2205 duplex stainless steel is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com