Method for one-step catalytic synthesis of ethylene glycol ethyl ether acetate

A technology of ethylene glycol ethyl ether acetate and ethyl acetate, which is applied in the field of fine chemicals, can solve problems such as easy environmental pollution, complicated process, and difficult product processing, and achieve low environmental pollution, high reactivity, and avoid product processing more difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

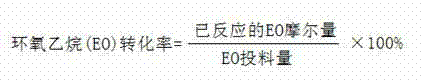

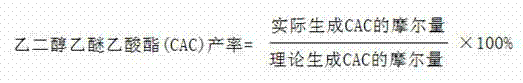

[0020] Add 176.2g ethyl acetate and 3.3g catalyst (magnesium aluminum zirconium salt cation molar ratio is Mg:Al:Zr=1:1:0.06) into a reaction kettle with a volume of 2L, and stir in a closed state with N 2 Replace the air in the kettle, heat up, and when the temperature reaches 120°C, continue to feed 44.0g of ethylene oxide into the reactor, the pressure in the reactor is 0.30~0.50MPa, and the reaction temperature is constant at 120°C. The molar ratio of the reaction raw materials is ethyl acetate: ethylene oxide = 2:1. The conversion rate of ethylene oxide was 76.99%, the yield of ethylene glycol ether acetate was 28.80%, and the yield of diethylene glycol ether acetate was 24.63%.

Embodiment 2

[0022] Add 211.4g ethyl acetate and 3.6g catalyst (magnesium aluminum zirconium salt cation molar ratio is Mg:Al:Zr=1:1:0.06) into a reaction kettle with a volume of 2L, close the stirring, and use N 2 Replace the air in the kettle, heat up, and when the temperature reaches 120°C, continue to feed 26.4g of ethylene oxide into the reactor, the pressure in the reactor is 0.30~0.50MPa, and the reaction temperature is constant at 120°C. The molar ratio of the reaction raw materials is ethyl acetate: ethylene oxide = 4:1. The conversion rate of ethylene oxide was 81.13%, the yield of ethylene glycol ether acetate was 41.37%, and the yield of diethylene glycol ether acetate was 25.16%.

Embodiment 3

[0024] Add 220.3g ethyl acetate and 3.7g catalyst (magnesium aluminum zirconium salt cation molar ratio is Mg:Al:Zr=1:1:0.06) into a reaction kettle with a volume of 2L, close the stirring, and use N 2 Replace the air in the kettle, heat up, and when the temperature reaches 120°C, continuously feed 22.0g of ethylene oxide into the reactor, the pressure inside the reactor is 0.30~0.50MPa, and the reaction temperature is constant at 120°C. The molar ratio of the reaction raw materials is ethyl acetate: ethylene oxide = 5:1. The conversion rate of ethylene oxide was 74.05%, the yield of ethylene glycol ether acetate was 41.74%, and the yield of diethylene glycol ether acetate was 21.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com