A kind of spherical boron nitride and its application

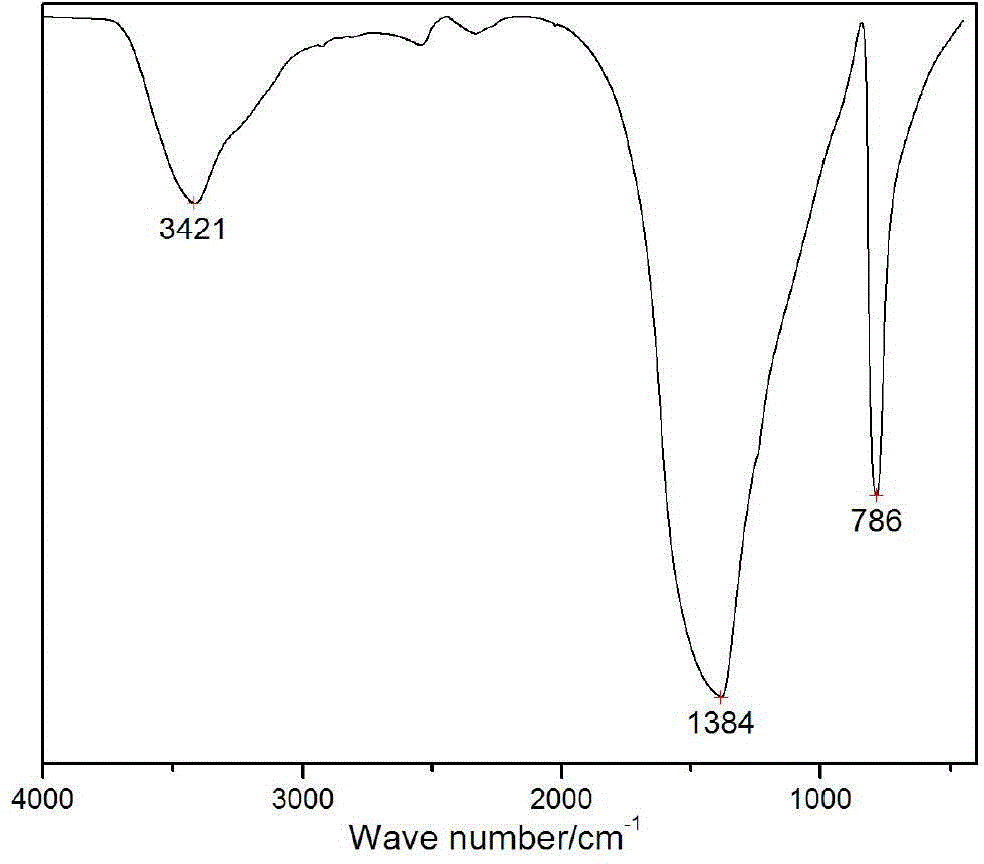

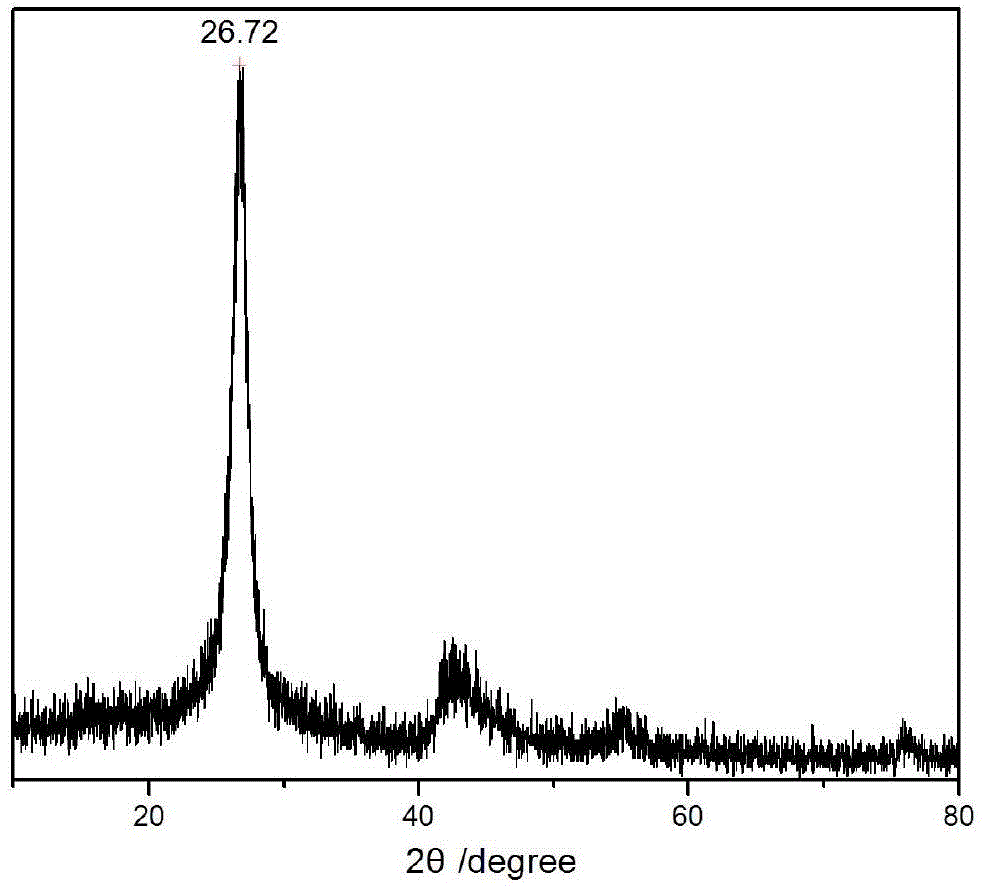

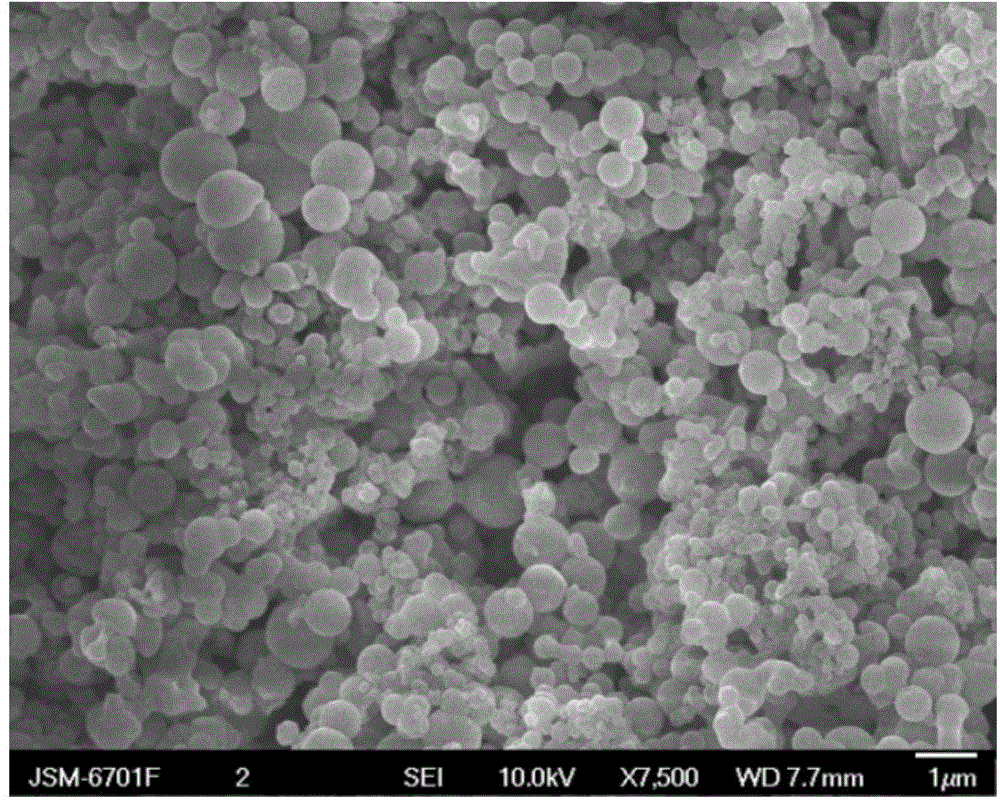

A boron nitride, spherical technology, applied in nitrogen compounds, inorganic chemistry, alkali metal compounds, etc., to achieve the effects of low reaction temperature, large specific surface area, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 spherical boron nitride

[0028] (1) Preparation method

[0029] 1) Dissolve glucose, urea and boric acid in a molar ratio of 1:1:1 in water with the assistance of magnetic stirring to obtain a colorless and transparent solution;

[0030] 2) Put the colorless and transparent solution into a 100ml stainless steel hydrothermal reaction kettle, put the reaction kettle into a constant temperature oven, and keep it warm at 180°C for 24 hours; naturally cool down to room temperature, filter the product, and wash it with water and ethanol several times in sequence , dried to give a brown solid;

[0031] 3) Put the brown solid in a high-temperature furnace, raise the temperature to 450°C at a rate of 1°C per minute under air atmosphere, and keep it at this temperature for 2 hours to obtain a light yellow solid;

[0032] 4) Put the light yellow solid in a container, under the protection of nitrogen, raise the temperature to 900°C at a rate of 1°C per minute, and k...

Embodiment 2

[0038] Embodiment 2 spherical boron nitride

[0039] The preparation method is the same as in Example 1, except that the molar ratio of glucose, urea and boric acid is changed. The results are shown in Table 1.

[0040] Table 1

[0041] Glucose: Urea: Boric acid

[0042] It can be seen from Table 1 that the size of the sphere can be controlled by changing the amount of glucose to meet different needs.

Embodiment 3

[0043] Example 3 spherical boron nitride

[0044] The preparation method is the same as in Example 1, except that the urea in step 1) is changed to melamine, biuret, ammonium chloride or ammonium nitrate respectively, and the results are shown in Table 2.

[0045] Table 2

[0046] nitrogen source

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com