Tire clamping mechanism for land leveller

A technology of clamping mechanism and grader, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of tire drop, large size and weight, and increase the working load of the telescopic end of lifting equipment, so as to reduce loss, The effect of increasing movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

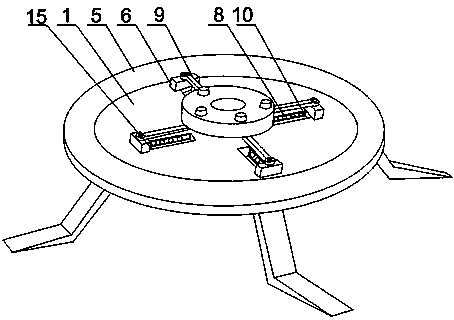

[0023] Such as Figure 1 to Figure 3 As shown, the motor grader tire clamping mechanism of the present invention includes a support cylinder 1, a baffle 3 is installed in the support cylinder 1, a motor 2 is fixedly arranged on the baffle 3, and the output end of the motor 2 passes through the baffle The plate 3 is connected with the turntable 4, and a plurality of horizontal grooves 15 are evenly arranged on the other end of the support cylinder 1, and claws are slidingly provided in the horizontal grooves 15; a connecting rod 9 is also included, and the connecting rod 9 One end is hinged with the turntable 4, the other end of the connecting rod 9 is hinged with the end of the claw, and a rectangular blind hole 10 is arranged on the inner wall of the horizontal groove 15, and a plurality of rollers 8 are installed in the rectangular blind hole 10; Position structure, the position-limiting structure is arranged on the baffle plate 3 . When the present invention works, put the...

Embodiment 2

[0025] Such as figure 1 with image 3As shown, this embodiment is based on Embodiment 1, the limiting structure includes a limiting plate 7, the limiting plate 7 is fixed on the baffle plate 3, and a through hole is opened in the middle of the limiting plate 7 , the motor output end 14 passes through the through hole, two grooves 12 are opened on the same side of the limiting plate 7, and the two grooves 12 are located on both sides of the motor output end 14, on the motor output end 14 A T-shaped block 13 is installed, and a travel switch 11 is installed in the groove 12, and the travel switch 11 is connected to the motor 2 through a wire. When clamping the tire placed horizontally, the motor 2 rotates to drive the T-shaped block 13 on the output end 14 of the motor to rotate, and when the claw slides to the outermost end of the horizontal groove 15, one end of the T-shaped block 13 and The travel switch 11 in the groove 12 contacts, and the travel switch 11 controls the mo...

Embodiment 3

[0027] Such as figure 1 with figure 2 As shown, in this embodiment, on the basis of Embodiment 1, the claws include an L-shaped slider 6, and the end of the vertical part of the L-shaped slider 6 is slidably arranged in the horizontal groove 15, and the L-shaped slider The end face of the horizontal portion of the block 6 is an inclined face. The horizontal portion of the L-shaped slider 6 can provide good support for the tire, ensuring that the center of the tire is always on the axis of the support cylinder 1 during the clamping movement. A plurality of L-shaped sliders 6 form a slider circle. When sliding When the block ring is in the shrinking state, the L-shaped slider 6 and the hinged block at the end of the horizontal part of the L-shaped slider 6 move to the center position of the tire. Driven by the connecting rod 9, the slider ring expands outward rapidly, and finally The L-shaped slider 6 clamps the inner ring of the tire to prevent the center of gravity of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com