A production process of vacuum low-temperature frying okra with different flavors

A vacuum low-temperature frying and production process technology, which is applied in food preparation, food coating, food science and other directions, can solve the problem of far different taste and color, and achieve the preservation of nutrients, natural color and taste, and prevention of browning. The effect of changing and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Raw material pretreatment: put the cleaned okra in hot water at 90°C for 5 minutes, and place it in cold water at 5°C for 1 minute;

[0047] (2) Freezing treatment: put the cooled okra into a quick freezer, and the temperature in the quick freezer is -30°C;

[0048] (3) Impregnation treatment: the okra after freezing is put into 20% maltose solution for ultrasonic-assisted vacuum impregnation for 35min, the ultrasonic power is 300W, the okra after the draining is put into a quick-freezing machine, and the temperature in the quick-freezing machine reaches-20°C;

[0049] (4) Vacuum frying: putting the okra after freezing into an oil temperature of 96°C in a low-temperature vacuum fryer and frying for 109 minutes;

[0050] (5) Deoiling: adopt a rotary centrifugal deoiler at 415 rpm, and perform centrifugal deoiling for 6 minutes to obtain the product.

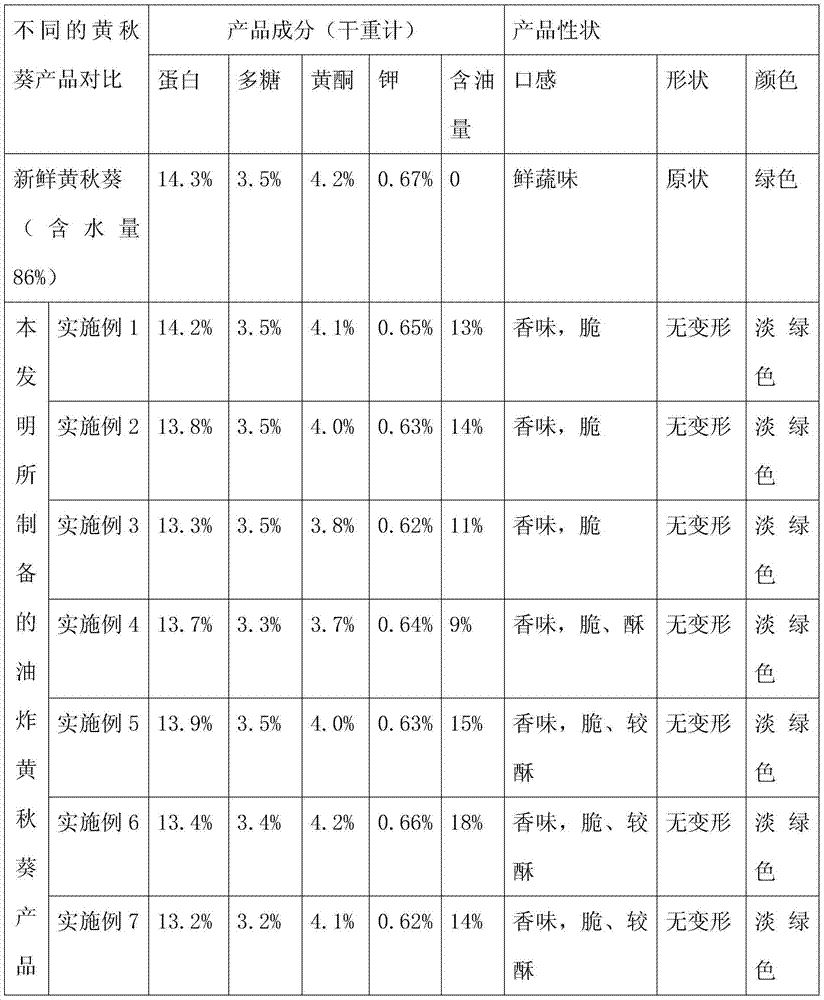

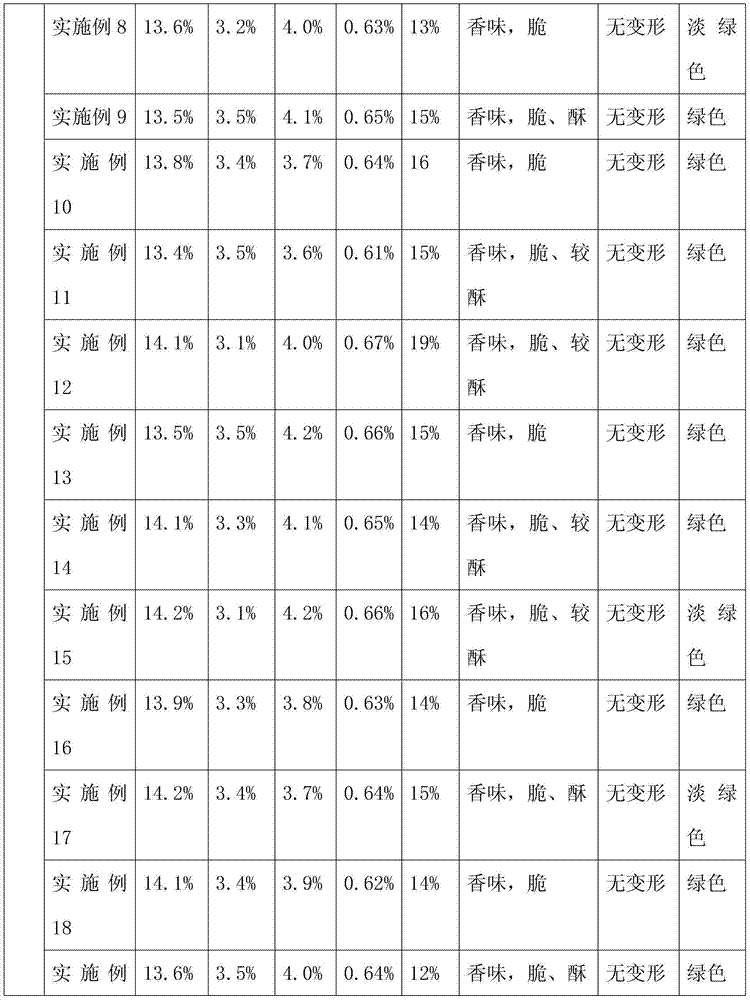

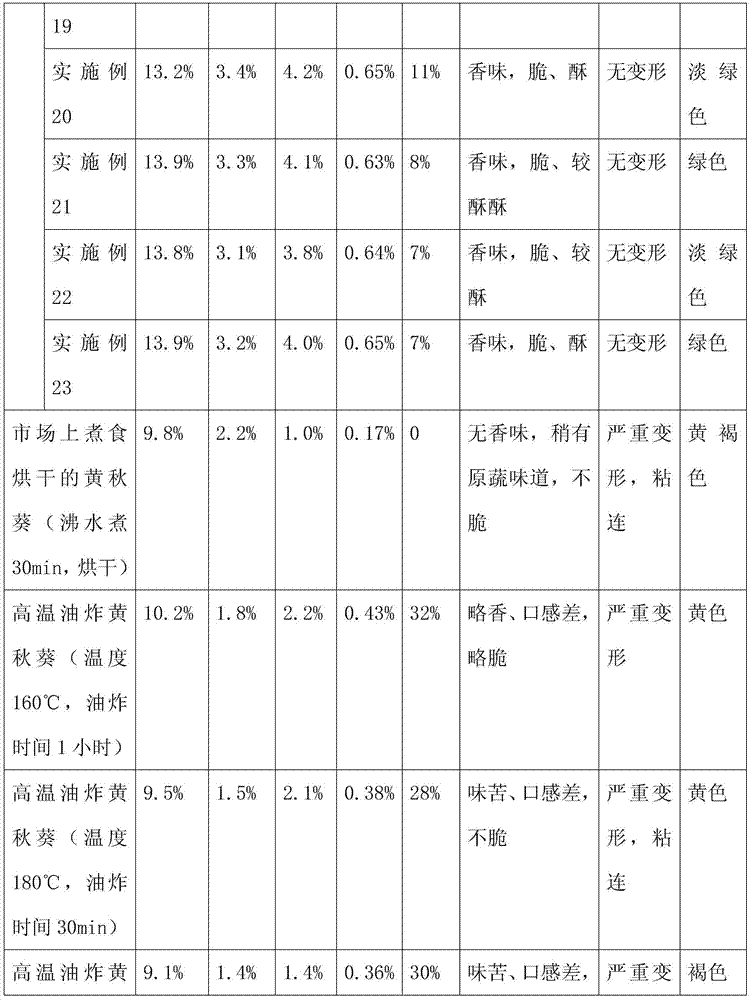

[0051] The indexes of the prepared products are shown in Table 1.

Embodiment 2

[0053] (1) Raw material pretreatment: put the washed okra in hot water at 80°C for 10 minutes, then put it in cold water at 10°C for about 1 minute;

[0054] (2) Freezing treatment: put the cooled okra into the quick-freezing machine, and the temperature in the quick-freezing machine reaches below -20°C;

[0055] The temperature inside the medium quick freezer is -23°C.

[0056] (3) Dipping treatment: the frozen okra is put into 20% (sugar content 20°) maltose and vacuum-impregnated for 0.5 hour, the okra after the draining is put into a quick freezer, and the temperature in the quick freezer reaches -20°C;

[0057] (4) Vacuum frying: put the frozen okra into a low-temperature vacuum fryer at 76°C and fry for 30 minutes;

[0058] (5) Deoiling: adopt a 330 rpm rotary centrifugal deoiler, and centrifugally deoil for 8 minutes to obtain the product.

Embodiment 3

[0060] (1) Raw material pretreatment: put the washed okra in hot water at 95° C. for 3 minutes, and put it in cold water at 0° C. for about 2 minutes.

[0061] (2) Freezing treatment: put the cooled okra into the quick-freezing machine, and the temperature in the quick-freezing machine reaches below -20°C;

[0062] (3) Dipping treatment: Put frozen okra into 30% concentration of maltose mixed with fructose and maltodextrin (maltose: maltodextrin = 1:2) and vacuum soak for 1.4 hours in the seasoning solution, put the drained okra into into the quick-freezer, and the temperature inside the quick-freezer reaches -30°C;

[0063] (4) Vacuum frying: Put the frozen okra into a low-temperature vacuum fryer with an oil temperature of 90° C. and fry for 90 minutes.

[0064] (5) Deoiling: adopt a 380 rpm rotary centrifugal deoiler, and centrifugally deoil for 7 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com