Metal filament body connecting method and connecting device

A connection method and a technology of a connection device, which are applied in the field of connection devices for metal wire bodies, and can solve problems such as increased workload, difficult passage of nodules, and increased flexural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

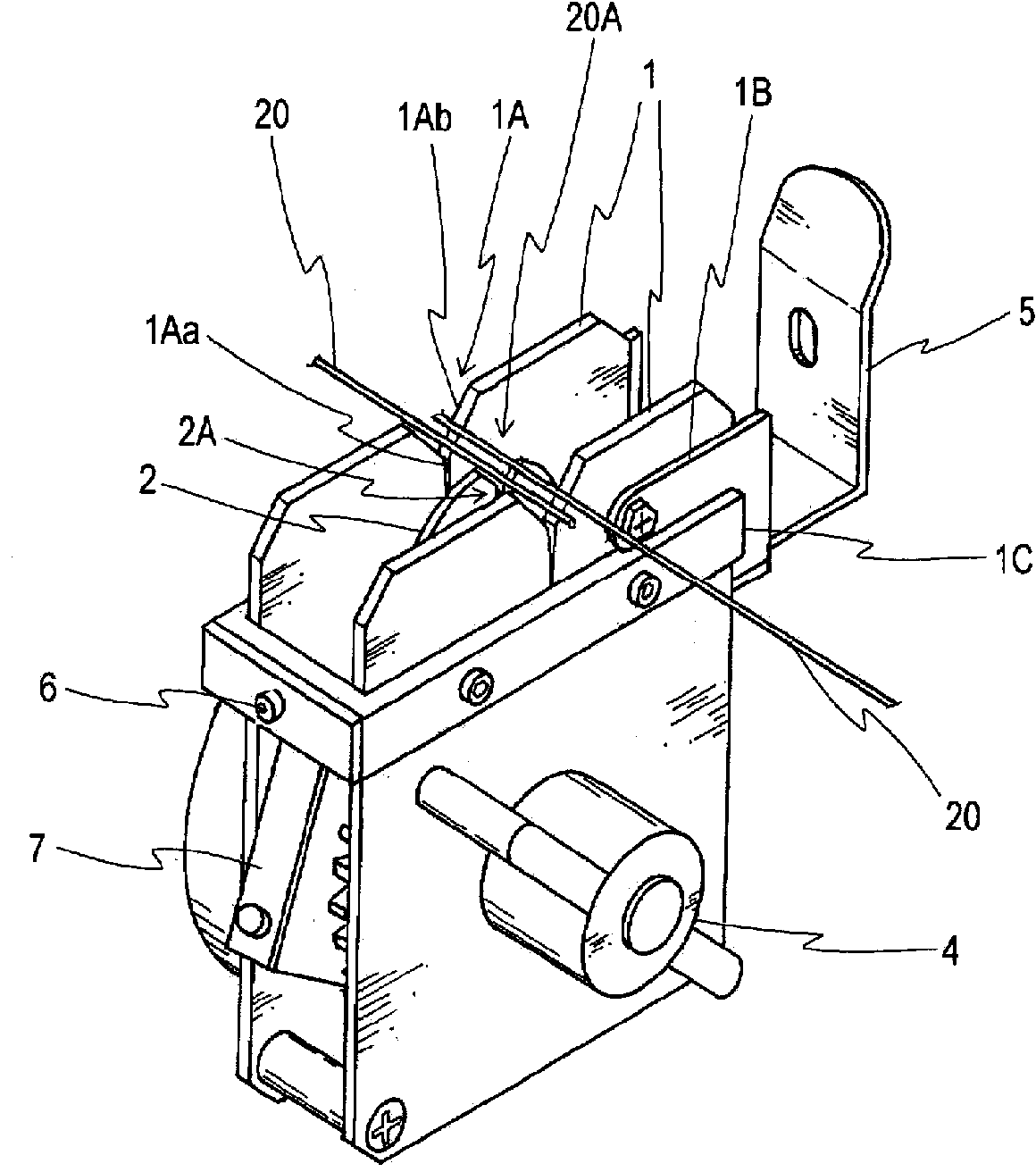

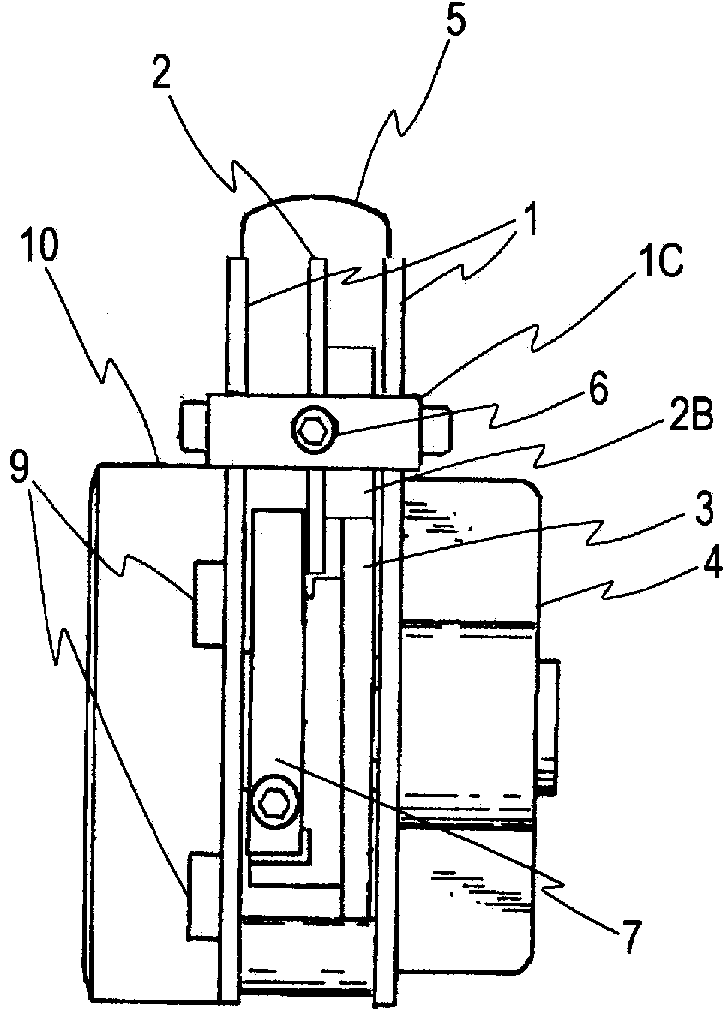

[0060] Hereinafter, the manufacturing method and manufacturing apparatus of the present invention will be described in detail with reference to examples.

[0061]

[0062] by using figure 1 A wire body connecting device of the type shown connects steel wires with a diameter of 0.45mm. The wire body holding member of the fixing member had an angle of 1.5° with respect to the depth direction of the notch portion, and a width of 0.46 mm. A guide with a width of 13 mm and an angle of 30° for guiding the steel wire was provided on the fixing member. The pressing force applied by the pressing member to the steel bar was set at 65N. The leaf spring has a length of 27mm, a width of 22mm and a thickness of 0.7mm. The time required to connect metal wire rods by using the connection device and the thickness of the nodule were measured. The results are listed in Table 1.

[0063]

[0064] Metal wire bodies having a diameter of 0.45 mm were connected by needle-nose pliers, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com