Laser efficient pulse discharge system

A pulsed discharge and laser technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as inability to achieve adjustment in a large time range, inability to perform high repetition frequency discharge, and damage to the matching state of pulsed discharge circuits. Achieve the effect of realizing repetitive frequency discharge operation, high repetition frequency discharge operation, and high average power laser output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

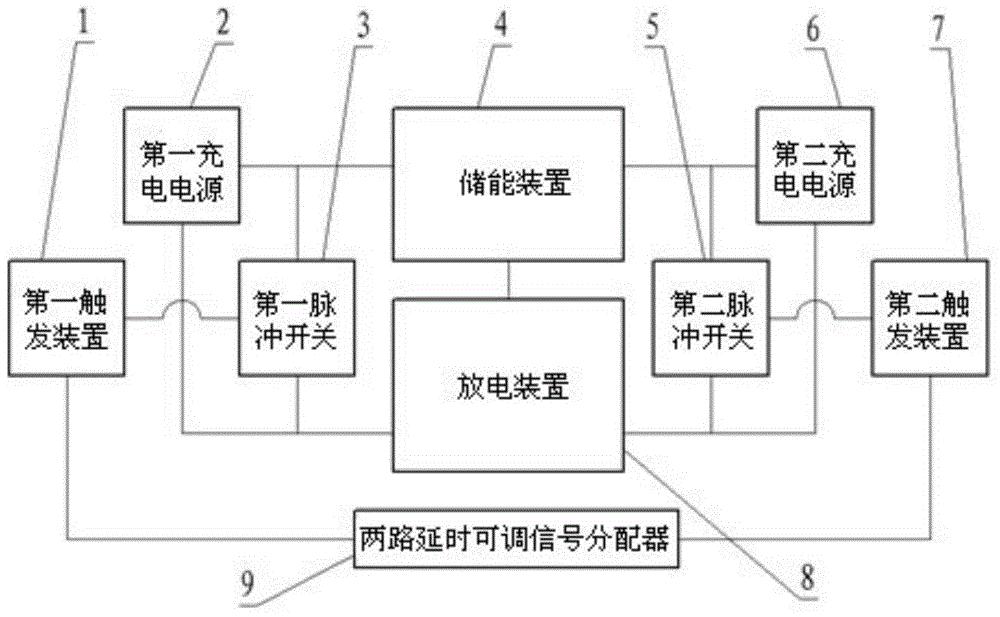

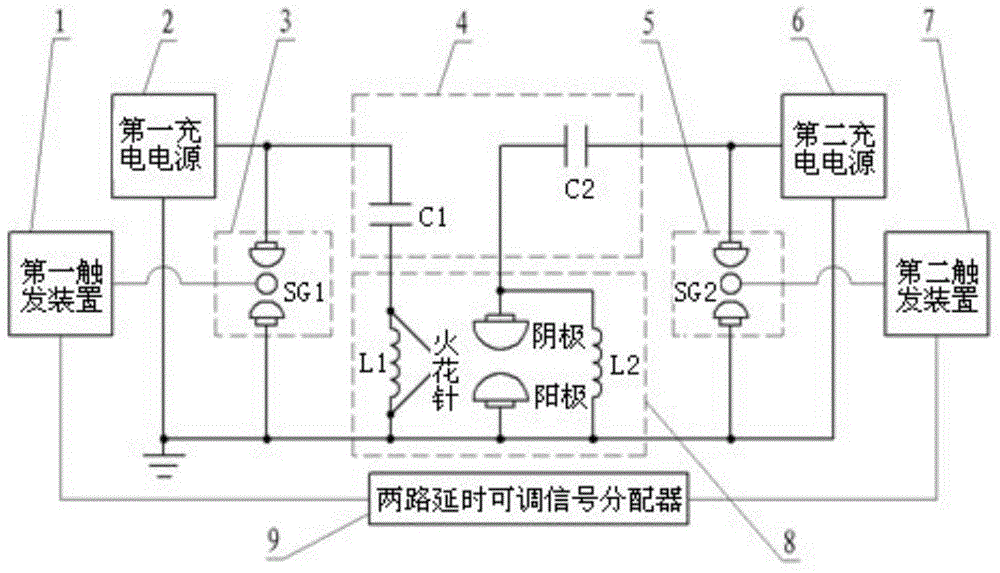

[0012] combine figure 1 with figure 2 In this embodiment, the laser high-efficiency pulse discharge system consists of a two-way delay adjustable signal distributor 9, a first charging power source 2, a second charging power source 6, a first triggering device 1, a second triggering device 7, a first pulse Switch 3 (SG1), second pulse switch 5 (SG2), energy storage device 4 (including pre-ionization energy storage capacitor C1, main discharge energy storage capacitor C2), discharge device 8 (including pre-ionization discharge circuit charge and discharge inductance L1 and Two rows of spark needles, the main electrode pair composed of the main discharge circuit charging and discharging inductance L2 and the cathode and anode).

[0013] The pulse discharge circuit of the laser high-efficiency pulse discharge system described in this embodiment includes two charging and discharging circuits, one of which is a pre-ionization charging and discharging circuit, which is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com