Preparation method of lithium battery LiNi0.5Mn1.5O4 positive electrode material with hollow structure

A cathode material, lithium battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of unsatisfactory cycle stability, low ion diffusion rate, etc., achieve excellent ionic conductivity, wide range of raw material sources, preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

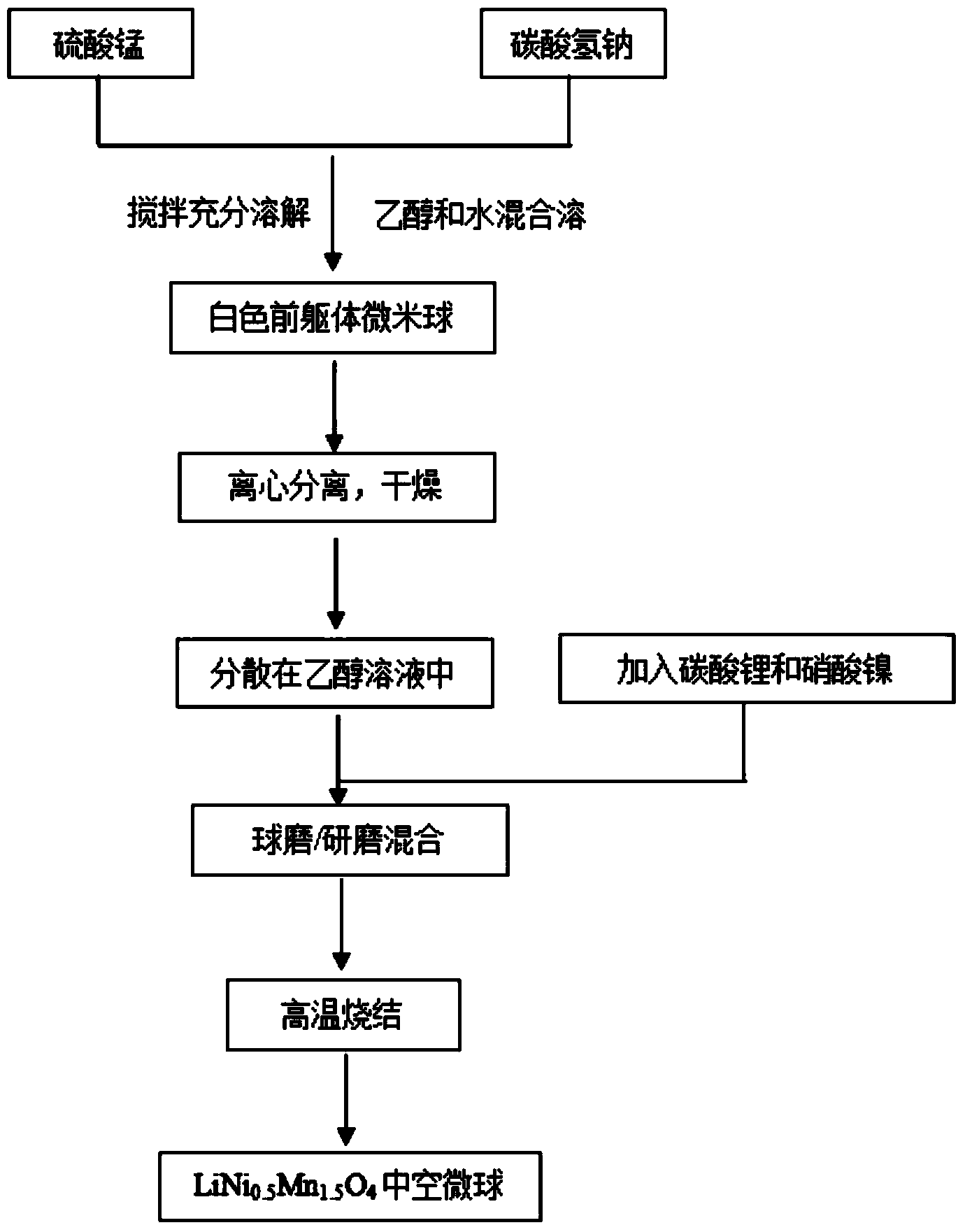

Method used

Image

Examples

Embodiment 1

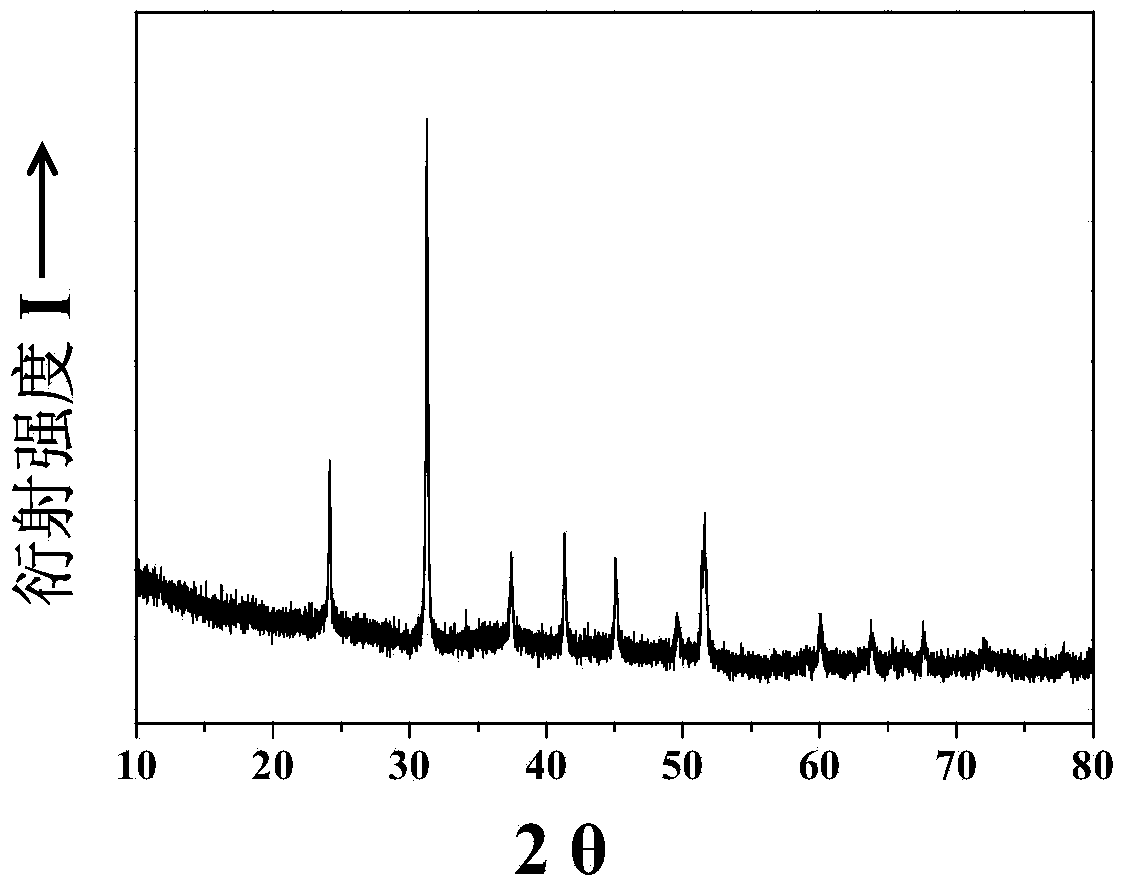

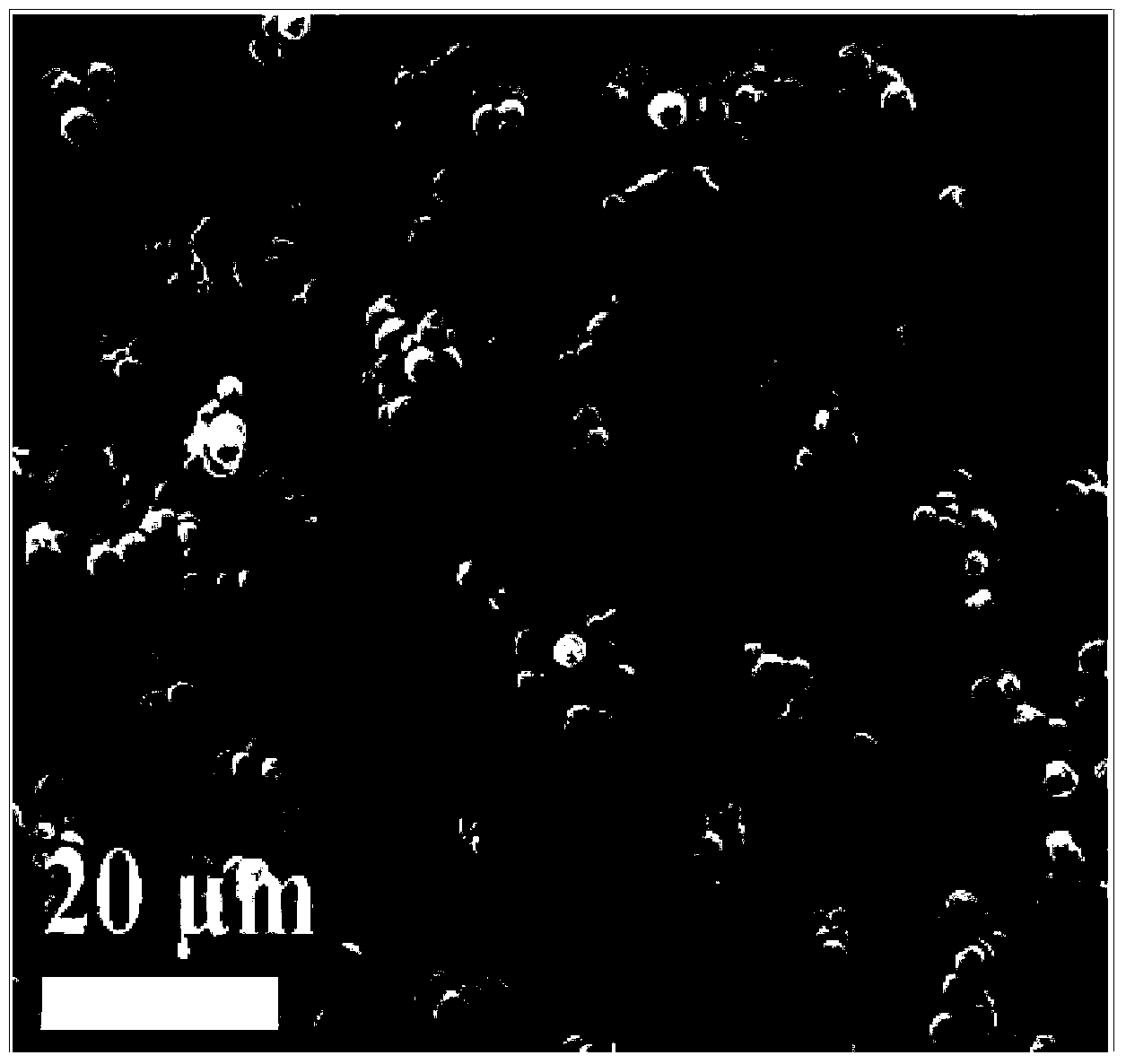

[0036] Under magnetic stirring at room temperature, 1.7075g of manganese sulfate and 4.1163g of sodium bicarbonate were dispersed in 35mL of absolute ethanol, and the solution was added to 700mL of absolute ethanol to immediately generate a white turbid solution. Continue stirring for 3h to complete the reaction. Separate and collect the MnCO by centrifugation 3 After the precursor product, it was washed with absolute ethanol and dried under vacuum at 60°C. X-ray diffraction pattern and electron microscopy photos show that the product is MnCO 3 Microsphere ( figure 2 , image 3 with Figure 4 ). 1.724g of MnCO synthesized by the above method 3 The microspheres were ground and mixed with 1.454 g nickel nitrate and 0.384 g lithium carbonate. The well-ground and mixed solid powder is placed in a muffle furnace and sintered at 800°C for 24 hours in an air atmosphere. X-ray diffraction patterns and transmission electron microscopy photographs indicate that the black product is a h...

Embodiment 2

[0038] At room temperature, the precursor MnCO was prepared according to Example 1 3 Micron spheres, together with 1.454 g nickel nitrate and 0.384 g lithium carbonate, were dispersed in 15 mL of absolute ethanol. After being fully mixed by a planetary ball mill for 1 hour, it is placed in a blast oven for drying, and placed in a muffle furnace at 800°C for 24 hours in an air atmosphere to obtain a hollow structure spinel LiNi 0.5 Mn 1.5 O 4 .

Embodiment 3

[0040] At room temperature, the precursor MnCO was prepared according to Example 1 3 Microsphere, 1.724g of MnCO synthesized by the above method 3 The microspheres were ground and mixed with 1.454 g nickel nitrate and 0.461 g lithium carbonate. The well-ground and mixed solid powder is placed in a muffle furnace and sintered at 800°C for 24 hours in an air atmosphere. Get spinel LiNi with hollow structure 0.5 Mn 1.5 O 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com