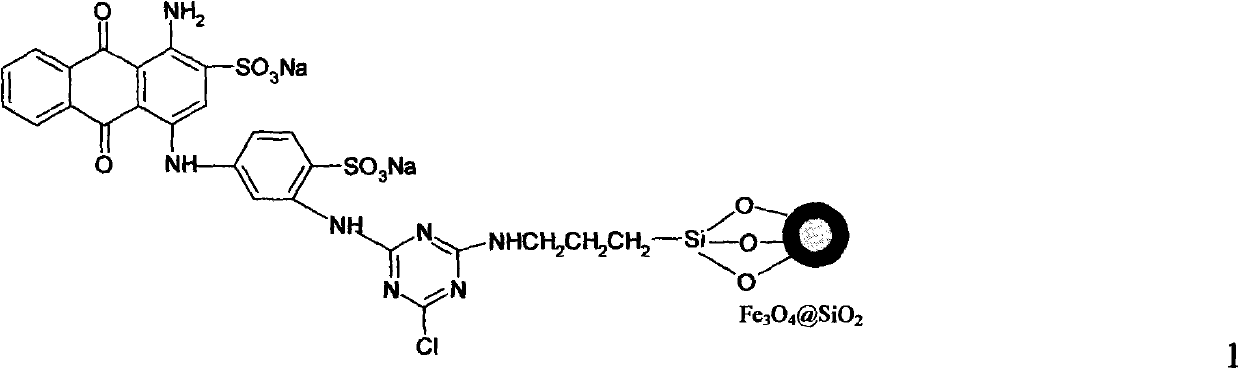

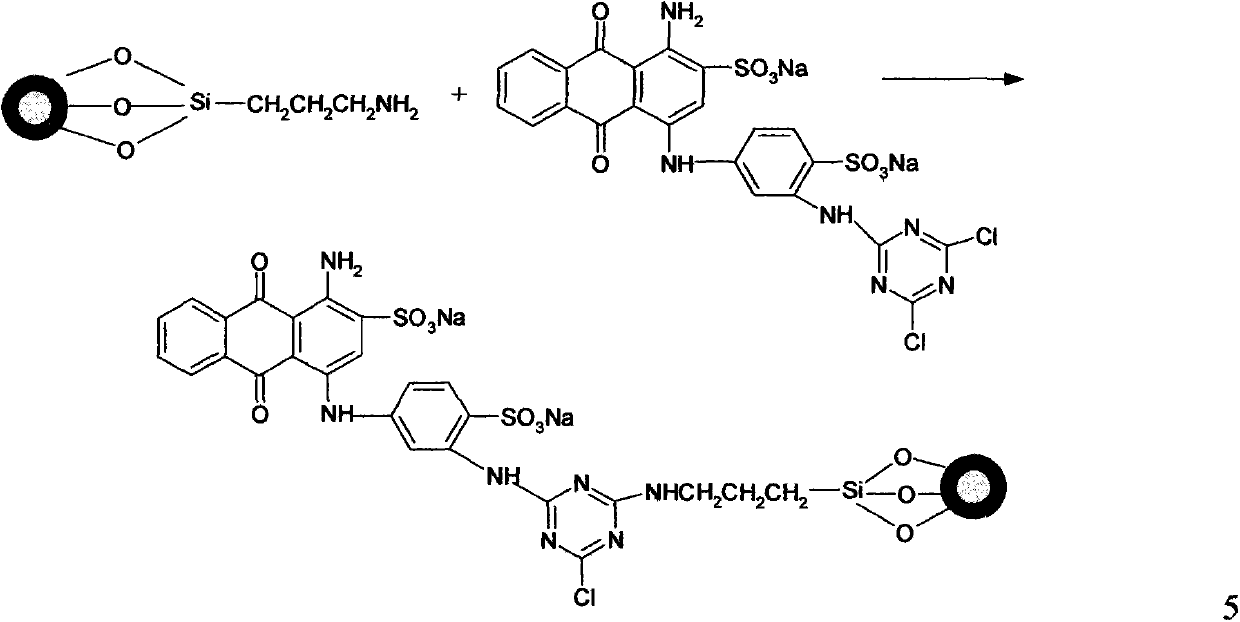

Separation of lysozyme by adopting zymoprotein affine magnetic nano particles

A magnetic nanoparticle and enzyme protein technology, applied in the direction of enzymes, hydrolases, glycosylases, etc., can solve the problems of low separation efficiency at low temperature, enzyme denaturation and inactivation, etc., and achieve large-capacity adsorption, little impact on activity, and enhanced separation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 5.5g FeCl 3 .6H 2 O and 2.8 g FeSO 4 .7H 2 O was dissolved in 50 mL of deionized water, at room temperature, under the protection of nitrogen, 2 mol / L sodium hydroxide solution was slowly added dropwise to it until the pH value of the solution was 11, and the reaction was stopped after stirring for 60 min. The solid particles obtained by magnetic separation are mixed with alcohol water solution and deionized water several times until the surface of the particles is neutral, and the magnetic Fe 3 o 4 Nanoparticles. 0.5g magnetic Fe 3 o 4Put the nanoparticles into a mixed solution of 150 mL of ethanol and water (volume ratio 4:1), adjust the pH value to 10 with 2 mol / L sodium hydroxide solution, and add 30 mL of ethyl silicate alcohol dropwise under nitrogen protection. Water mixed solution (containing 1.0 mL of ethyl silicate) was reacted at room temperature for 5 h. After magnetic separation, wash with alcohol-water mixed solution, ion water, and absolute ethano...

Embodiment 2

[0028] 5.5g FeCl 3 .6H 2 O and 2.8 g FeSO 4 .7H 2 O was dissolved in 50 mL of deionized water, at room temperature, under the protection of nitrogen, 2 mol / L sodium hydroxide solution was slowly added dropwise to it until the pH value of the solution was 11, and the reaction was stopped after stirring for 4 h. The solid particles obtained by magnetic separation are mixed with alcohol water solution and deionized water several times until the surface of the particles is neutral, and the magnetic Fe 3 o 4 Nanoparticles. 0.5g magnetic Fe 3 o 4 Put the nanoparticles into a mixed solution of 150 mL of ethanol and water (volume ratio 4:1), adjust the pH value to 10 with 2 mol / L sodium hydroxide solution, and add 30 mL of ethyl silicate alcohol dropwise under nitrogen protection. Mix the solution with water (containing 1.0 mL of ethyl silicate), and finish the reaction at room temperature for 5 h. After magnetic separation, wash with alcohol-water mixed solution, ion water, a...

Embodiment 3

[0032] 5.5g FeCl 3 .6H 2 O and 2.8 g FeSO 4 .7H 2 O was dissolved in 50 mL of deionized water, and under nitrogen protection, 2 mol / L sodium hydroxide solution was slowly added dropwise at 50 °C until the pH of the solution was 11, and the reaction was stopped after stirring for 6 h. The solid particles obtained by magnetic separation are mixed with alcohol water solution and deionized water several times until the surface of the particles is neutral, and the magnetic Fe 3 o 4 Nanoparticles. 0.5g magnetic Fe 3 o 4 Put the nanoparticles into a mixed solution of 150 mL of ethanol and water (volume ratio 4:1), adjust the pH value to 10 with 2 mol / L sodium hydroxide solution, and add 30 mL of ethyl silicate alcohol dropwise under nitrogen protection. Water mixed solution (containing 1.5 mL of ethyl silicate) was reacted at room temperature for 5 h. After magnetic separation, wash with alcohol-water mixed solution, ion water, and absolute ethanol three times until the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com