Method used for taking pollen and triblock copolymer as templates for synthesizing of mesoporous silica microspheres

A technology of mesoporous silica and copolymers, which is applied in the directions of silica, silica, medical preparations with inactive ingredients, etc. Ability, effect of large-scale industrial promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Synthesis process of mesoporous silica microspheres:

[0034] (1) Clean rapeseed pollen with ethanol ultrasonically for 3 times, take it out, rinse it repeatedly with ethanol and water and dry it;

[0035] (2) Add 1 g of triblock copolymer P123 and 5 g of hydrochloric acid solution with a concentration of 2 mol / L into 95 g of deionized water, stir to dissolve, add 1 g of rapeseed pollen, stir for 1 day, then add 2.08 g of ethyl orthosilicate, Stir in a water bath at 40°C for 3 days;

[0036] (3) The impregnated product is taken out, washed and dried in sequence, and the washing can be done by first washing with absolute ethanol aqueous solution, and then washing with deionized water. Calcined at 550° C. for 3 hours, cooled naturally to obtain mesoporous silica microspheres.

[0037] The resulting mesoporous silica microspheres were characterized as follows:

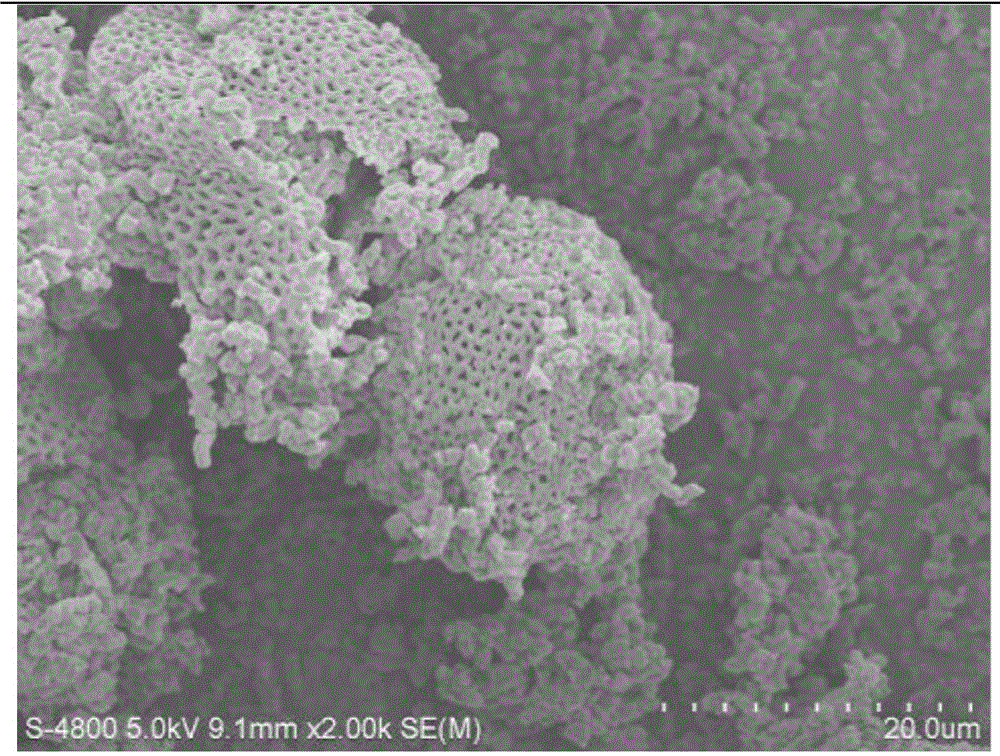

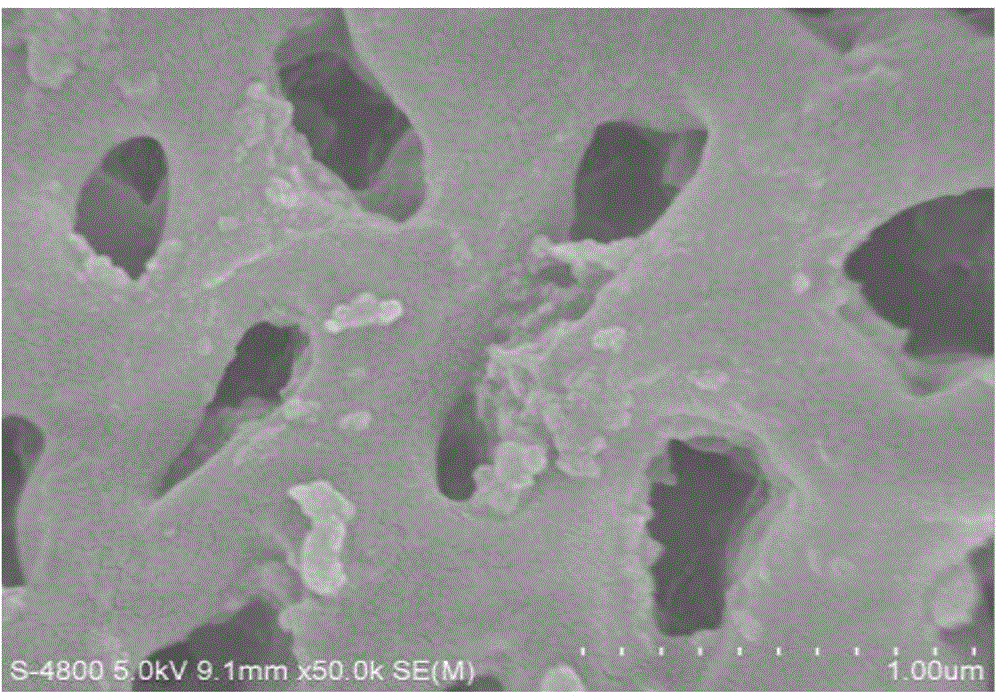

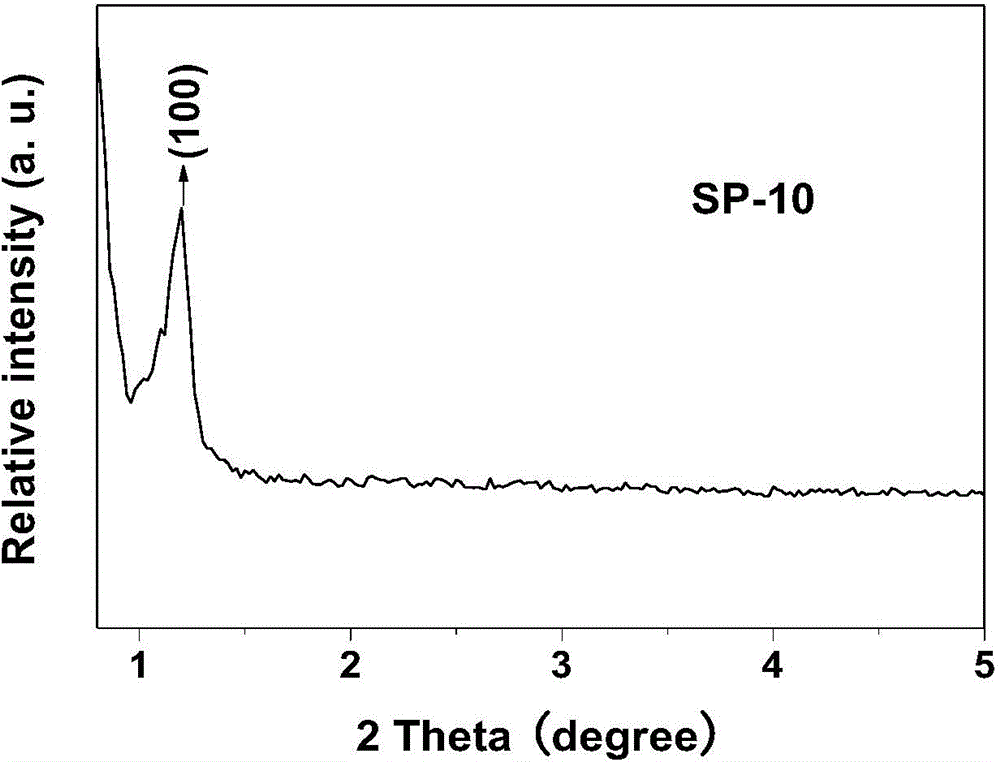

[0038] Such as figure 1 shown, from figure 1 It can be seen that the material is a spherical shape with r...

Embodiment 2

[0043] Synthesis process of mesoporous silica microspheres:

[0044] (1) Ultrasonic cleaning of camellia powder with ethanol for 3 times, after taking it out, rinse it with ethanol and water repeatedly and dry it;

[0045] (2) Add 2 g of triblock copolymer P123 and 8 g of hydrochloric acid solution with a concentration of 2 mol / L into 110 g of deionized water, stir to dissolve, add 1.5 g of camellia powder, stir for 3 days, then add 3 g of tetraethyl orthosilicate, Stir in a water bath at 40°C for 3 days;

[0046] (3) Take out the impregnated product, wash and dry in sequence. The cleaning can be done by first washing with anhydrous ethanol aqueous solution, then washing with deionized water, calcining at 700°C for 3 hours, taking out after natural cooling to obtain mesoporous silica Microspheres.

[0047] The mesoporous silica microspheres prepared by the above method are shown in Figure 4 , it can be seen that the diameter of a single ball is about 15 μm, there is basica...

Embodiment 3

[0049] Synthesis process of mesoporous silica microspheres:

[0050] (1) Clean rapeseed pollen with ethanol ultrasonically for 3 times, take it out, rinse it repeatedly with ethanol and water and dry it;

[0051] (2) Add 2 g of triblock copolymer F127 and 10 g of hydrochloric acid solution with a concentration of 2 mol / L into 120 g of deionized water, stir to dissolve, add 2 g of rapeseed pollen, stir for 1 day, add 4 g of tetraethyl orthosilicate, 40 Stir in a water bath for 1 day;

[0052] (3) Take out the impregnated product, wash and dry in sequence. The cleaning can be washed with anhydrous ethanol aqueous solution first, then washed with deionized water, calcined at 600°C for 5 hours, and taken out after natural cooling to obtain mesoporous silica Microspheres.

[0053] The mesoporous silica microspheres prepared by the above method are shown in Figure 5 , it can be seen that the diameter of a single sphere is about 12 μm, there is basically no breakage and agglomera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com