Novel shore container transfer method and transfer system

A technology for containers and container ships, which is applied to storage devices, transportation and packaging, and trolley cranes, etc. It can solve the problems of large design structure, high lifting height, and affecting transshipment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

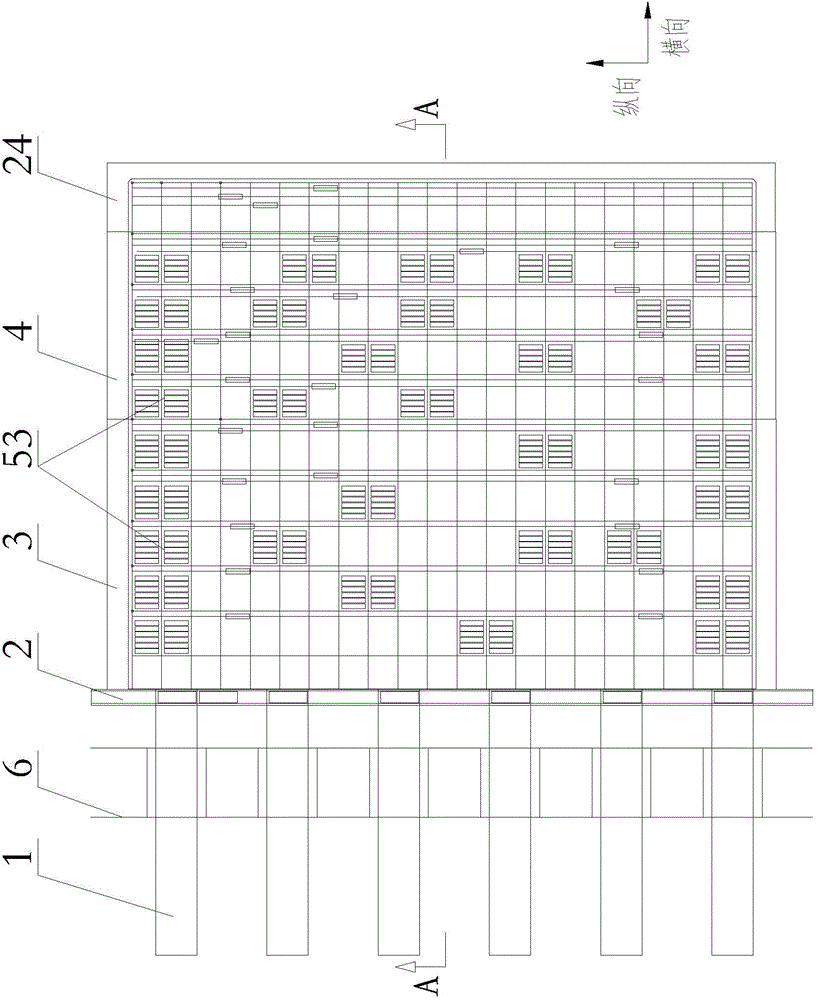

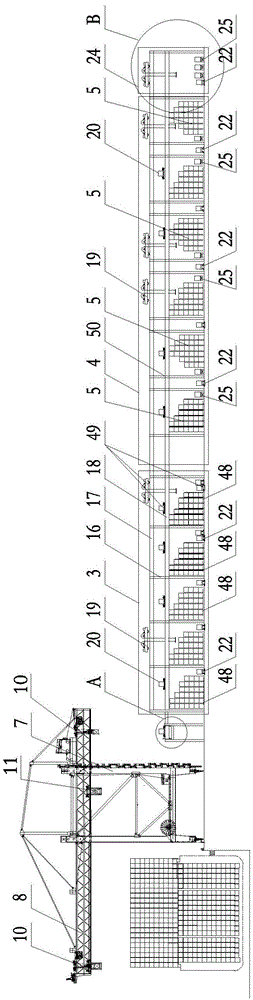

[0099] Embodiment 1 of the present invention: a novel shore container transshipment method: it includes the methods of unloading, dredging the port, transferring, entering and loading;

[0100] The unloading process includes the following steps:

[0101] Step 1: When the container ship is docked at the port, more than one container quay crane 1 walks on the track a6, so that one end of the quay bridge girder 8 on the container quay crane 1 is located directly above the container ship, and then the quay crane is adjusted sequentially After the distance between the girder 8 and the highest container on the container ship is adjusted, lock the girder 8 of the quay bridge on the gantry 7 of the quay bridge;

[0102] Step 2: The quay crane hoist trolley 10 on the upper layer of the quay bridge girder 8 begins to pick up the container on the container ship and hoist the container on the quay crane transfer trolley 11 on the lower layer of the quay bridge girder 8. At this time, the ...

Embodiment 2

[0120] Embodiment 2 of the present invention: a novel shoreside container transshipment method: it includes the methods of unloading, clearing the port, transferring, entering and loading;

[0121] The unloading process includes the following steps:

[0122] Step 1: When the container ship is docked at the port, more than one container quay crane 1 walks on the track a6, so that one end of the quay bridge girder 8 on the container quay crane 1 is located directly above the container ship, and then the quay crane is adjusted sequentially After the distance between the girder 8 and the highest container on the container ship is adjusted, lock the girder 8 of the quay bridge on the gantry 7 of the quay bridge;

[0123] Step 2: The quay crane hoist trolley 10 on the upper layer of the quay bridge girder 8 begins to pick up the container on the container ship and hoist the container on the quay crane transfer trolley 11 on the lower layer of the quay bridge girder 8. At this time, ...

Embodiment 3

[0141] Embodiment 3 of the present invention: a novel shoreside container transshipment method: it includes the methods of unloading, clearing the port, transferring, entering and loading;

[0142] The unloading process includes the following steps:

[0143] Step 1: When the container ship is docked at the port, more than one container quay crane 1 walks on the track a6, so that one end of the quay bridge girder 8 on the container quay crane 1 is located directly above the container ship, and then the quay crane is adjusted sequentially After the distance between the girder 8 and the highest container on the container ship is adjusted, lock the girder 8 of the quay bridge on the gantry 7 of the quay bridge;

[0144] Step 2: The quay crane hoist trolley 10 on the upper layer of the quay bridge girder 8 begins to pick up the container on the container ship and hoist the container on the quay crane transfer trolley 11 on the lower layer of the quay bridge girder 8. At this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com