An automatic magnetic slag removal machine for swirling wells

A swirl well and slag removal machine technology, which is applied in the field of steel rolling wastewater treatment, can solve the problems of wasting time, manpower and material resources, poor sanitation of the working environment, and the use of a large amount of manpower, so as to save energy, manpower, and cleaning efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

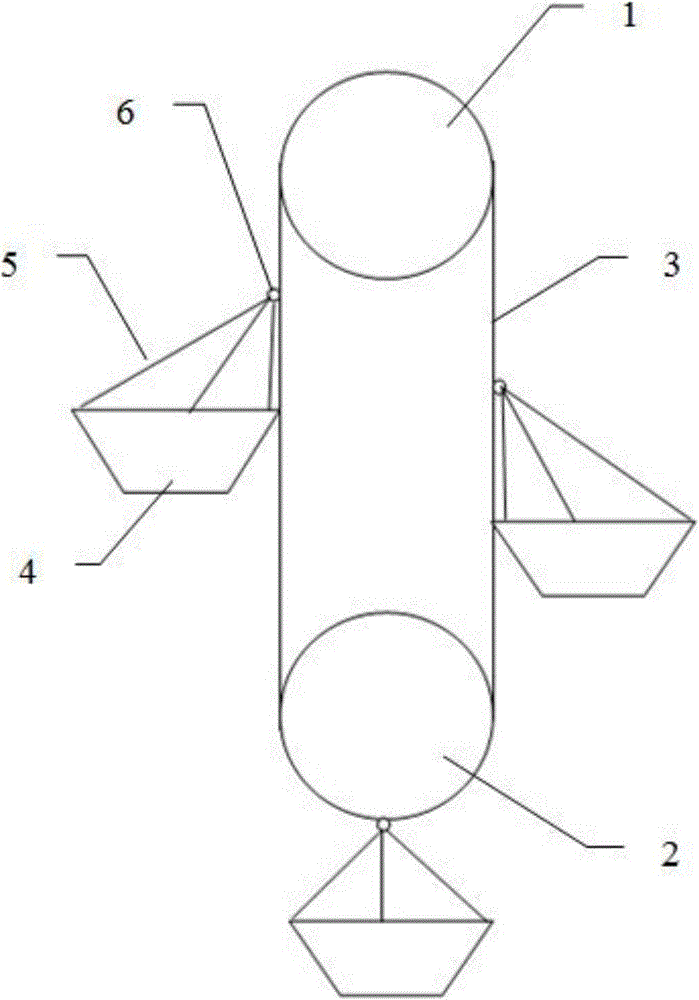

[0021] Such as figure 1 As shown, a kind of cyclone well automatic magnetic slag removal machine according to the present invention comprises:

[0022] The transmission mechanism includes a rotating wheel and a transmission belt 3, and the rotating wheel includes a first rotating wheel 1 and a second rotating wheel 2, and the first rotating wheel 1 and the second rotating wheel 2 are arranged longitudinally and have a certain interval, so The rotating wheel is connected with a motor and is driven to rotate, and the transmission belt 3 is wound around the outside of the first rotating wheel 1 and the second rotating wheel 2 and is driven to rotate by the rotating wheel, forming a longitudinally running through the rotating wheel. Transmission mechanism inside the flow w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com