Plasma torch for dielectric heating

A plasma and medium heating technology, applied in the direction of plasma, electrical components, etc., can solve the problems that cannot meet the use requirements of harmful waste gas treatment, achieve clean combustion, compact structure, and overcome the effect of low gasification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

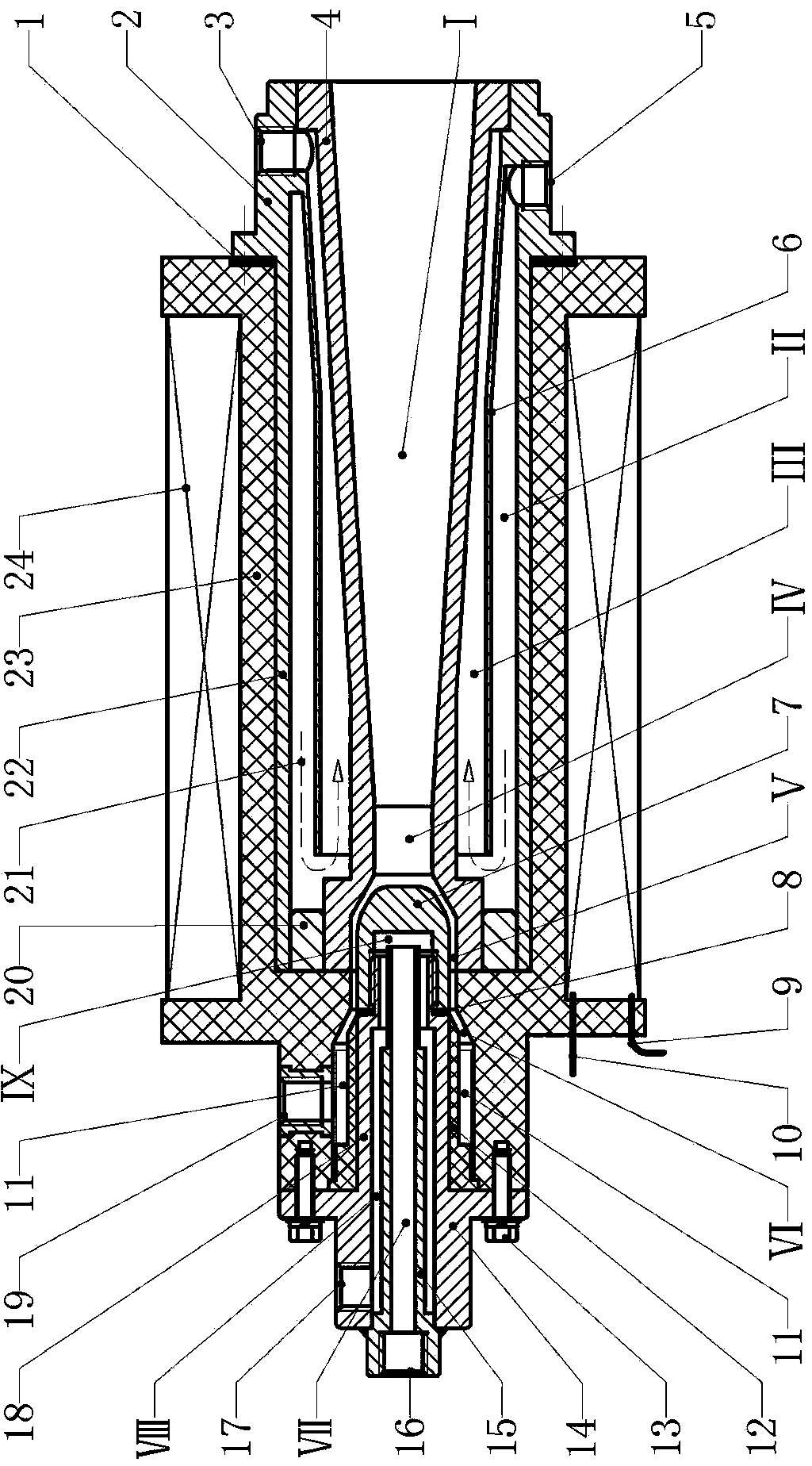

[0017] Embodiments In the embodiment shown in the drawings, a plasma spray gun for medium heating mainly consists of a front gun body (2), an anode (4), a rear gun body (14), a cathode (7) and an insulating frame (23 ), wherein, the front gun body (2) has a rotary structure, and the front gun body (2) has a diversion sleeve (6) and a barrel (22) extending backward, and the diversion sleeve (6) is in the In the inner space of the barrel (22), there is a head (20) in the front gun body (2); the anode (4) is embedded in the rotary body of the front gun body (2), and the anode (4) is connected to the front gun body ( 2) Assembled with interference fit, the front part of the anode (4) has a horn-shaped structure that gradually narrows from front to back. The inner space of the horn-shaped structure constitutes the ion arc channel (I), and the rear part of the horn-shaped structure is The round hole-shaped throat constitutes the compression channel (Ⅳ), the hole ratio of the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com