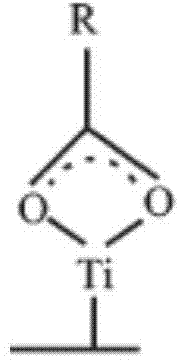

Lithium titanate negative electrode material and preparation method thereof and lithium ion battery using material

A negative electrode material, lithium titanate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as water content increase, achieve the effects of reduced absorption, simple preparation method, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing lithium titanate with surface hydrophobization, comprising the following steps:

[0037] 1) Disperse 10g of lithium titanate particles in 50mL of ethanol and stir evenly to obtain a uniformly dispersed mixture;

[0038] 2) Add 5g of dodecanoic acid into 50mL of ethanol, stir until completely dissolved, and obtain dodecanoic acid solution;

[0039] 3) Add the mixed liquid obtained in step 1) and the aqueous solution of dodecanoic acid obtained in step 2) into the same hydrothermal solution;

[0040] 4) Seal the water heater and place it at 100°C for 24 hours before cooling;

[0041] 5) After the hydrothermal solution is naturally cooled to room temperature, filter it with suction, wash the obtained solid particles with ethanol three times, dry them under vacuum, and then heat them at 250°C for 1 hour under nitrogen flow to obtain dodecanoic acid coated on the surface Carboxylated lithium titanate.

Embodiment 2

[0043] This embodiment provides a method for preparing lithium titanate with surface hydrophobization, comprising the following steps:

[0044] 1) Disperse 20g of lithium titanate particles in 100mL of propanol and stir evenly to obtain a uniformly dispersed mixture;

[0045] 2) Add 5g of octanoic acid into 50mL of ethanol, stir until completely dissolved, and obtain octanoic acid solution;

[0046]3) Add the mixed liquid obtained in step 1) and the octanoic acid aqueous solution obtained in step 2) to the same hydrothermal solution;

[0047] 4) Seal the water heater and place it at 100°C for 12 hours before cooling;

[0048] 5) After the hydrothermal solution is naturally cooled to room temperature, filter it with suction, wash the obtained solid particles with propanol three times, dry them under vacuum, and then heat them at 250°C for 1 hour under nitrogen flow to obtain caprylic acid carboxyl groups coated on the surface. lithium titanate.

Embodiment 3

[0050] This embodiment provides a method for preparing lithium titanate with surface hydrophobization, comprising the following steps:

[0051] 1) Disperse 15g of lithium titanate particles in 50mL of isopropanol and stir evenly to obtain a uniformly dispersed mixture;

[0052] 2) Add 7g of octadecanoic acid into 50mL of isopropanol, stir until completely dissolved, and obtain octadecanoic acid solution;

[0053] 3) Add the mixed solution obtained in step 1) and the octadecanoic acid aqueous solution obtained in step 2) to the same hydrothermal solution;

[0054] 4) Seal the water heater and place it at 100°C for 24 hours before cooling;

[0055] 5) After the hydrothermal solution is naturally cooled to room temperature, filter with suction, wash the obtained solid particles with ethanol three times, dry under vacuum, and then heat under nitrogen flow at 250°C for 1 hour to obtain octadecanoic acid coated on the surface Carboxylated lithium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com