Aqueous lithium ion battery electrode, preparation method of electrode and aqueous lithium ion battery

A lithium-ion battery and lithium-ion technology, applied in electrode manufacturing, secondary batteries, active material electrodes, etc., can solve the problems of low battery operating voltage, low charge and discharge voltage, and difficulty in finding electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

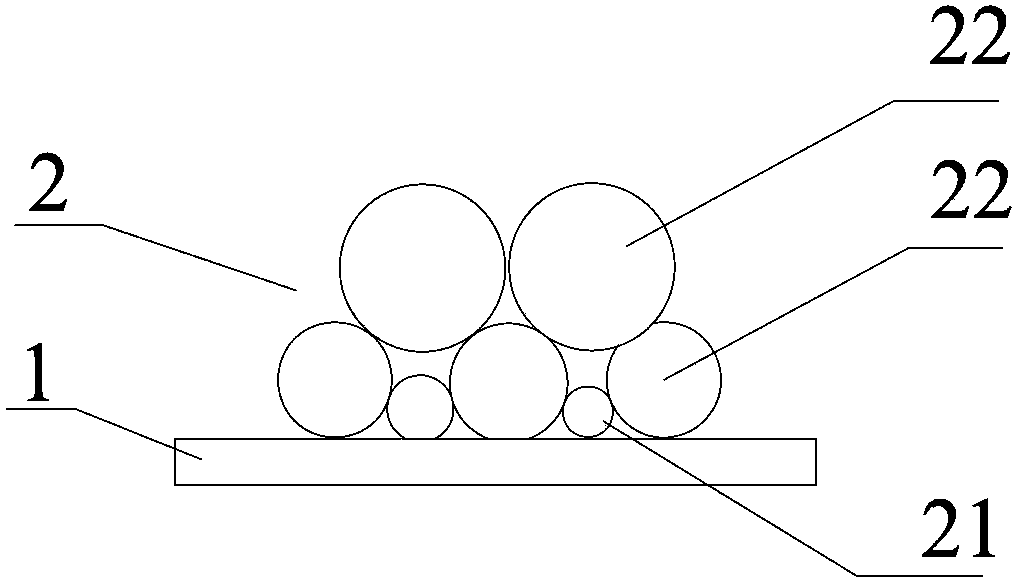

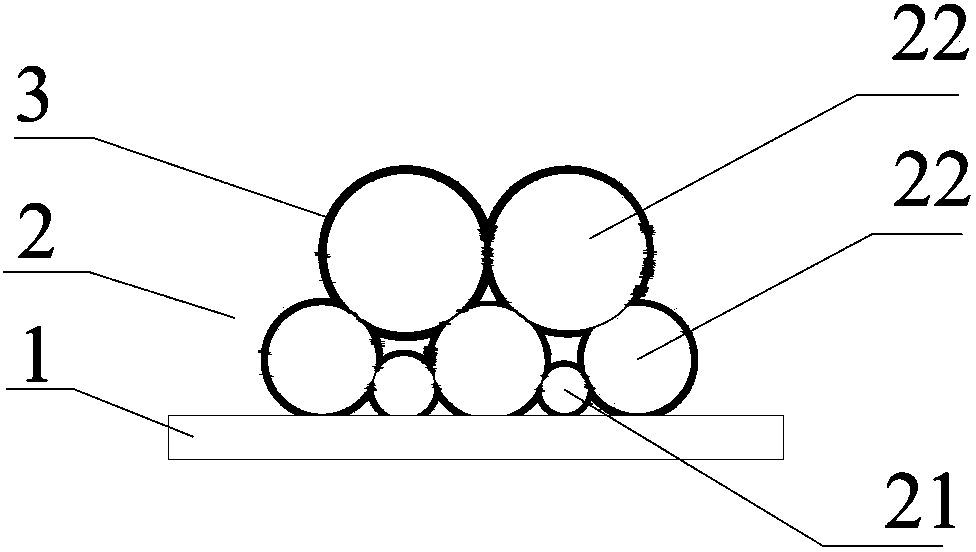

[0064] Correspondingly, the embodiment of the present invention also provides a method for preparing the electrode of the above-mentioned aqueous lithium-ion battery. For the process flow of the electrode preparation method for the aqueous lithium-ion battery, please refer to Figure 5 , see also Figures 2 to 4 . The electrode preparation method of the aqueous lithium ion battery comprises the following steps:

[0065] Step S01. Prepare a lithium-ion-containing polymer slurry that is electrically insulated and conductive to lithium ions: mix the lithium-ion-containing polymer that is electronically insulated but conductive to lithium ions with a solvent to prepare a polymer slurry material;

[0066] Step S02: Coating the polymer slurry on the electrode: coating the polymer slurry prepared in step S01 on the electrode containing the active material layer 2, forming the protective layer 3 after drying treatment, and obtaining the aqueous lithium Ion battery electrodes.

[006...

Embodiment 1

[0088] A positive electrode and a negative electrode aqueous lithium-ion battery electrode and a preparation method thereof, and an aqueous lithium-ion battery:

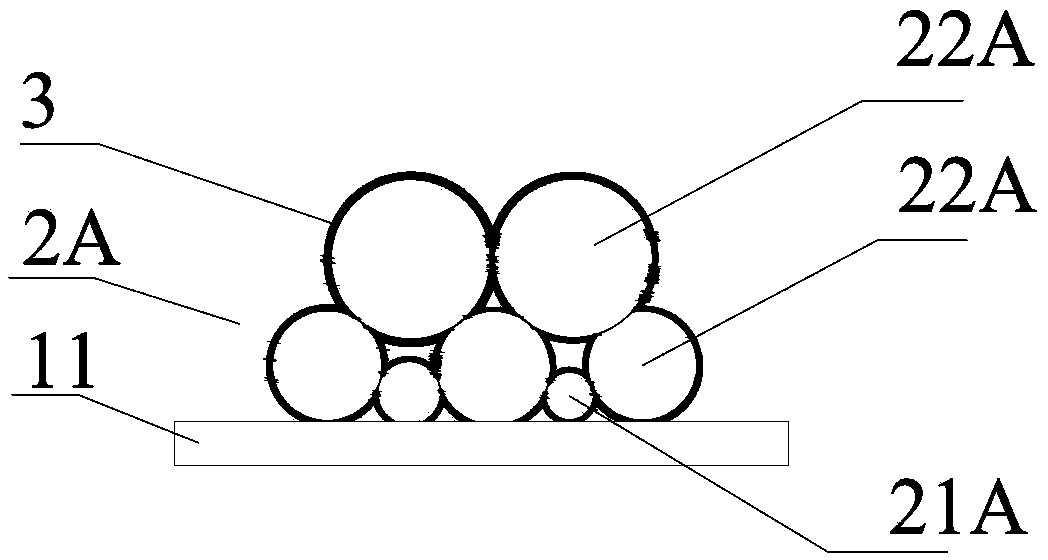

[0089] The electrode structure of the positive electrode aqueous lithium ion battery is as follows: image 3 As shown, it includes aluminum foil current collector 11, LiNiCoMnO combined on the surface of aluminum foil current collector 11 2 The positive electrode active material layer 2A and the protective layer 3 combined on the surface of the positive electrode active material layer 2A and on the pore walls of the positive electrode active material layer 2A. Wherein, the material of the protective layer 3 is lithium polyethacrylate.

[0090] The electrode structure of the negative electrode aqueous lithium ion battery is as follows: Figure 4 As shown, it includes a copper foil current collector 12, an artificial graphite negative electrode active material layer 2B bonded on the surface of the copper foil current...

Embodiment 2

[0100] A positive electrode and a negative electrode aqueous lithium-ion battery electrode and a preparation method thereof, and an aqueous lithium-ion battery:

[0101] The positive electrode aqueous lithium ion battery electrode structure in Example 1 is the positive electrode aqueous lithium ion battery electrode structure, and the negative electrode aqueous lithium ion battery electrode structure is the negative electrode aqueous lithium ion battery electrode structure in Example 1.

[0102] 2.1 The cathode aqueous lithium-ion battery electrode is prepared as follows:

[0103] Preparation of positive electrode sheet: refer to the preparation of step 1.1 positive electrode sheet in Example 1;

[0104] Preparation of lithium polyacrylate slurry: slowly add 100 grams of lithium polyacrylate into a beaker filled with 900 grams of acetone, stir evenly, and obtain a lithium polyacrylate solution with a concentration of 10%;

[0105] Coating the lithium polyacrylate slurry on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com