Series-parallel connection centrifugal pump

A centrifugal pump and parallel technology, applied in the field of centrifugal pumps, can solve problems such as large workload, uncontrollable work, leakage, etc., and achieve the effect of improving service life, physical sealing performance and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

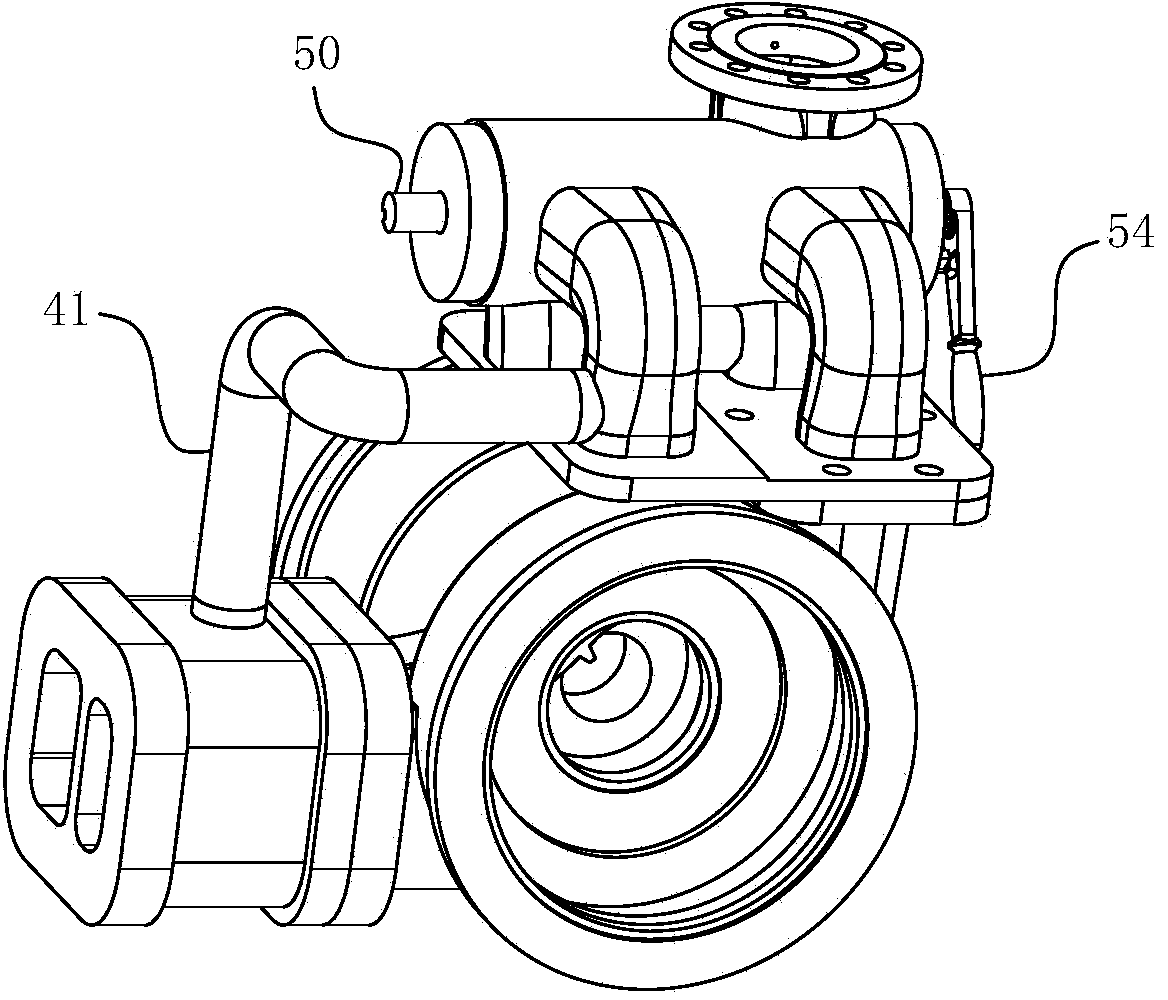

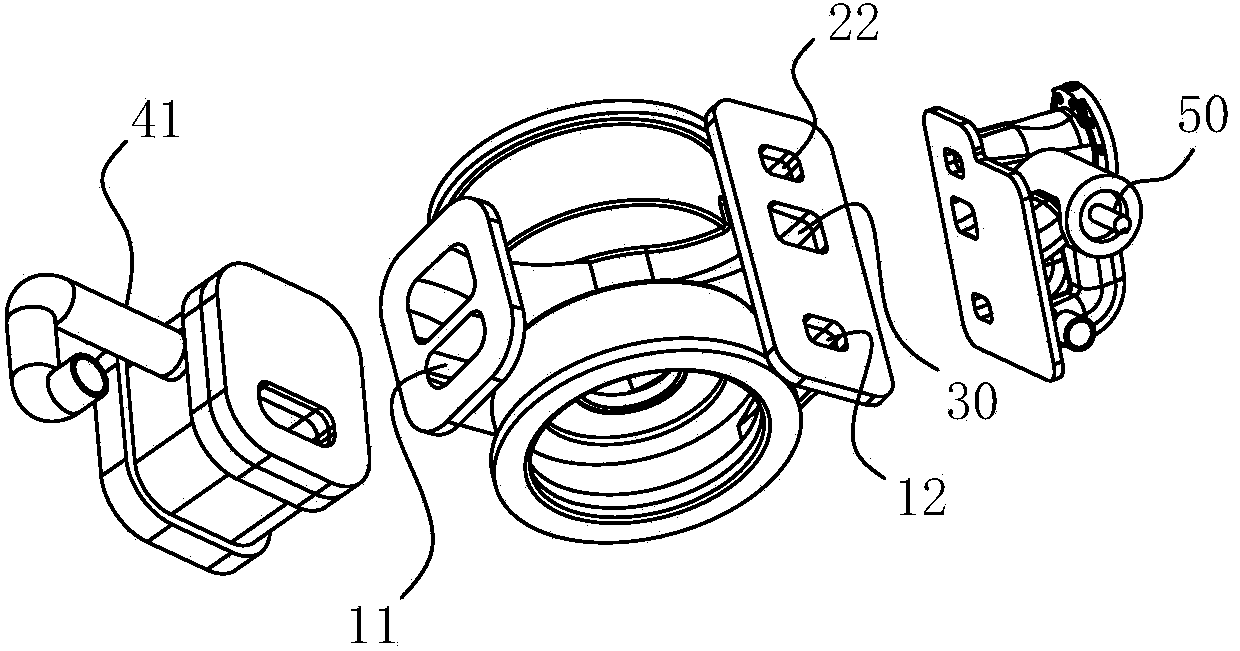

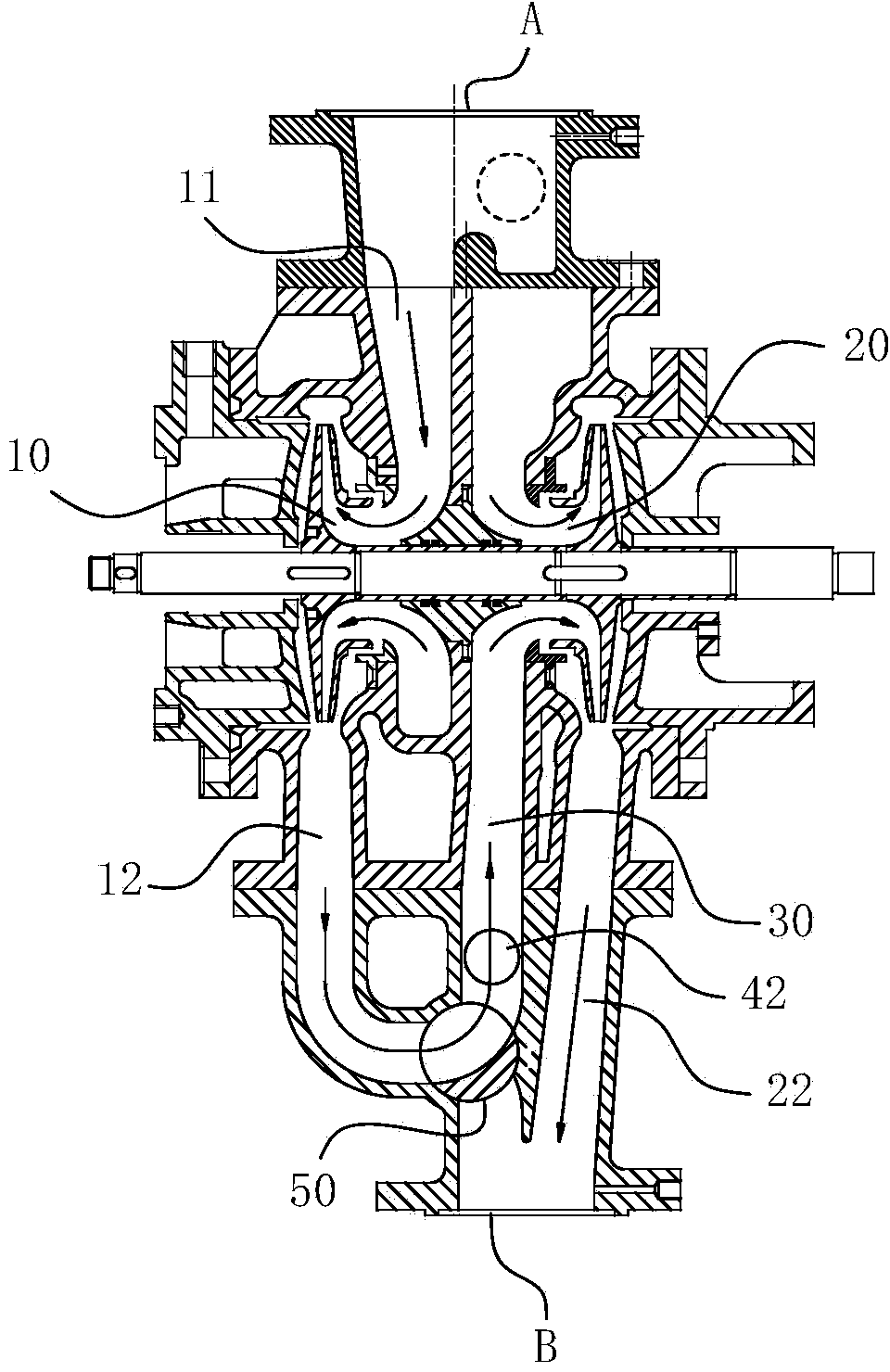

[0040] For ease of understanding, combined here Figure 1-13 Concrete components and workflow of the present invention are described as follows:

[0041] The present invention adopts such as Figure 1-13 The rotary valve body structure shown in the figure realizes the operation purpose of "one valve and two controls". To achieve the purpose of series-parallel operation relative to the pump body; in this way, on the one hand, the position of the switch part that could not be directly controlled manually is controlled by the valve core that also controls the switch component, which has stronger controllability, working stability and reliability. The performance can be greatly guaranteed, and at the same time, it also has a favorable impact on its actual service life; 30, the first liquid outlet flow channel 11 and even the connecting pipe 42 are moved to the outlet end of the pump body and communicate with each other to form an integral part, and then the pipe body 41 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com