Jacking pulling combined rectangular jacking pipe tunnel construction method

A technology for rectangular pipe jacking and tunnel construction, which is applied to tunnels, earthwork drilling, mining equipment, etc., and can solve problems such as limiting the applicable breadth of rectangular pipe jacking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

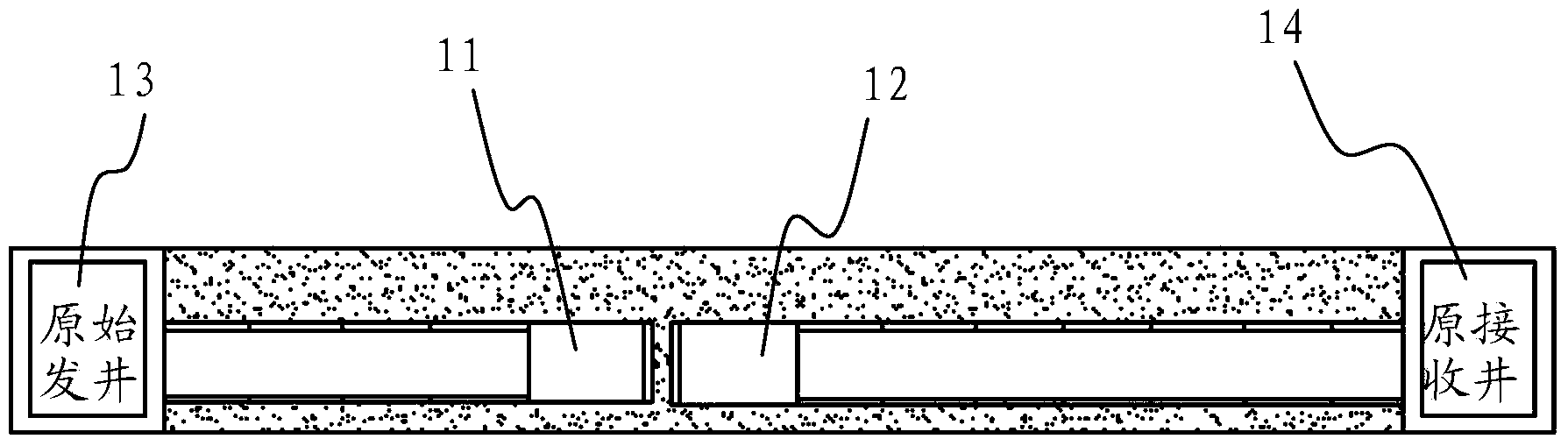

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] refer to Figure 1~3 As shown, the construction method of the present invention's top-pull combination rectangular pipe jacking tunnel specifically includes the following construction steps:

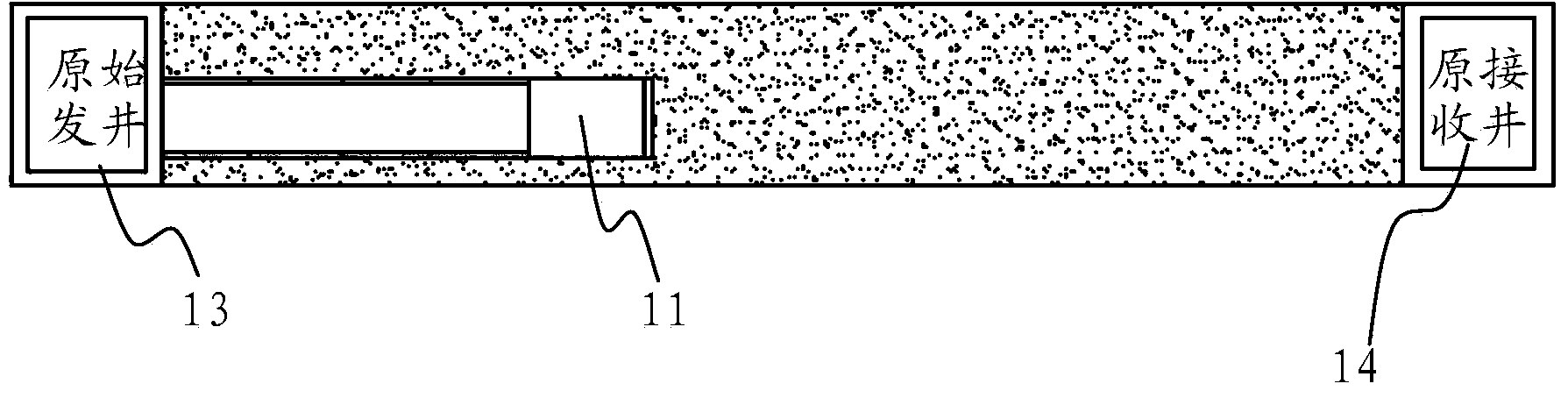

[0037] S001. Determine the position of the faulty pipe jacking machine 11, such as figure 1 shown.

[0038] When determining the position of the faulty pipe jacking machine 11, measure the elevation, slope and rotation angle of the faulty pipe jacking machine 11 as the data basis for subsequent construction, and continue to track and measure during the subsequent construction process.

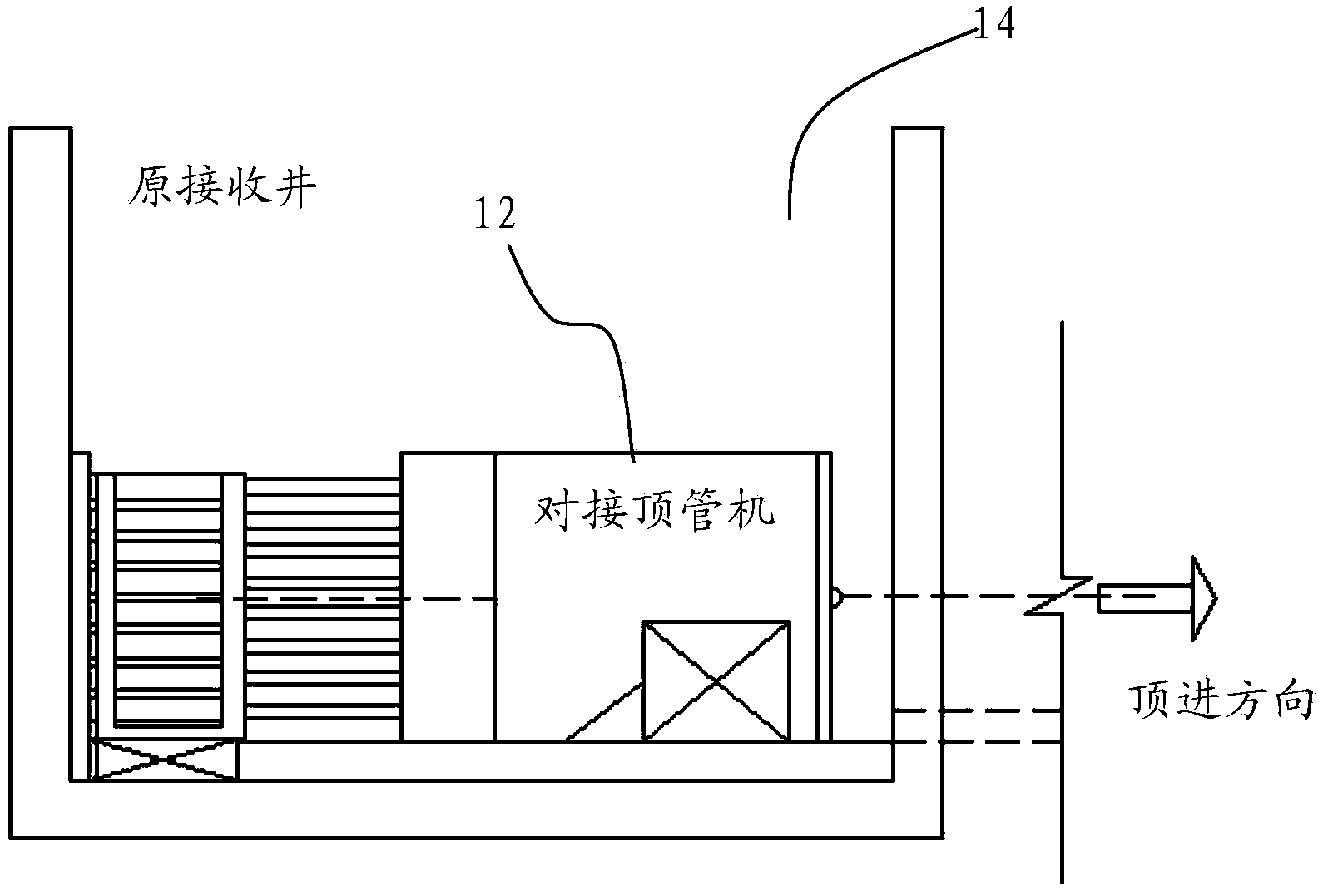

[0039] S002. Provide a pair of pipe jacking machines 12, such as figure 2 As shown, the starting base and guide rails of the docking pipe jacking machine 12 are arranged in the original receiving shaft 14 . Determine the jacking axis of the butt pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com