A kind of high wear-resistant material and its manufacturing method and application

A manufacturing method and high wear-resistant technology, applied in the field of compressor materials, can solve the problems of increased austenite quantity, high cost of raw materials, poor dimensional stability, etc., and achieve the effects of improved reliability, uniform distribution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

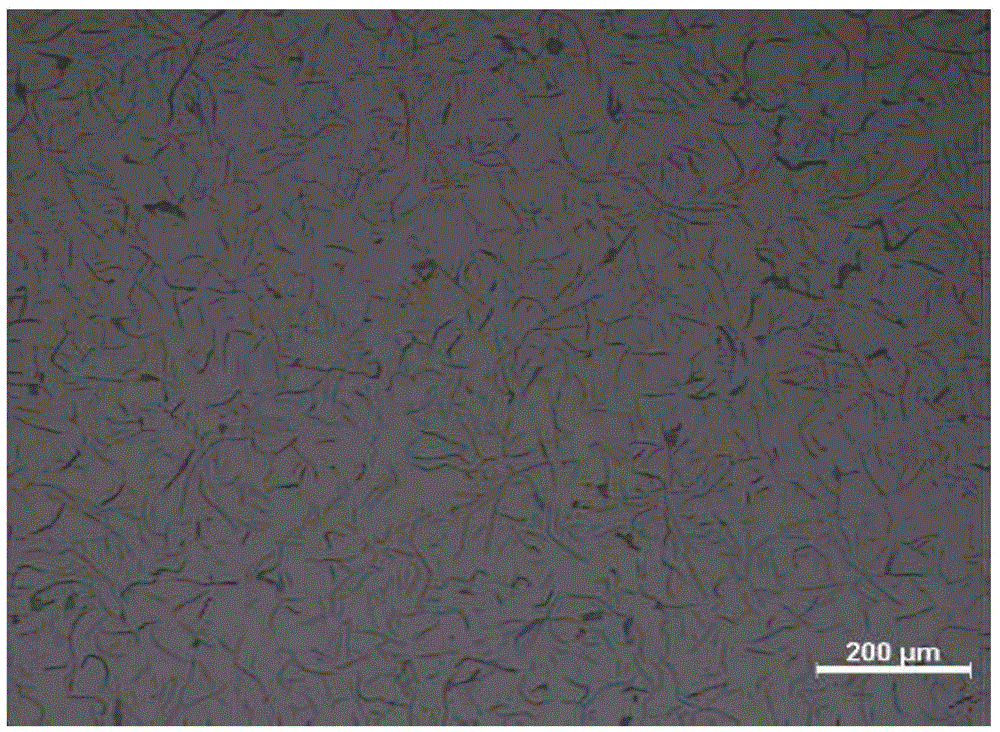

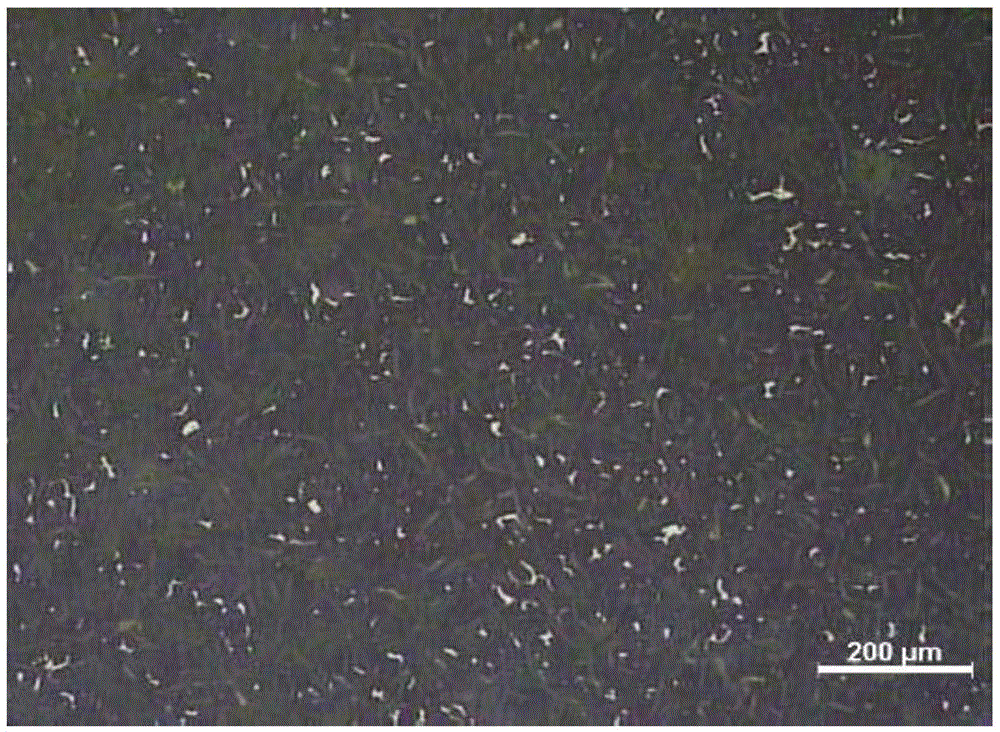

Image

Examples

Embodiment 1

[0044] The chemical composition (mass fraction %) of the piston material of the present embodiment is as follows:

[0045] C: 3.15; Si: 2.3; Mn: 0.8; S: ≤0.15; P: 0.25; B: 0.08; Cu: 0.4;

[0046] (1) The materials according to the above chemical composition ratios are melted into molten iron using an intermediate frequency electric furnace, and the melting temperature is controlled at 1450°C to 1600°C, which is 1580°C in this embodiment.

[0047] (2) Pour molten iron into the holding furnace, and use ferrosilicon or barium silicon inoculant to inoculate with the flow at the same time;

[0048] (3) The molten iron is poured into the casting ladle from the holding furnace, and the secondary inoculation treatment is carried out during injection; the casting temperature of the molten iron is kept at: 1300° C. to 1540° C., which is 1470° C. in this embodiment.

[0049] (4) The molten iron is poured from the casting ladle into the cavity of the sand mold, and the molten iron is coo...

Embodiment 2

[0058] The chemical composition (mass fraction %) of the piston material of the present embodiment is as follows:

[0059] C: 3.2; Si: 2.4; Mn: 0.6; S: ≤0.15; P: 0.25; B: 0.08; Cu: 0.4; Sn: 0.02;

[0060] The preparation method is the same as in Example 1. The obtained piston was excellent in wear resistance.

Embodiment 3

[0062] The chemical composition (mass fraction %) of the piston material of the present embodiment is as follows:

[0063] C: 3.2; Si: 2.5; Mn: 0.6; S: ≤0.15; P: 0.25; B: 0.10; Cu: 0.6; Sn: 0.02;

[0064] The preparation method is the same as in Example 1. The obtained piston was excellent in wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com