Soluble magnesium-base alloy material, and preparation method and application thereof

A magnesium-based alloy, soluble technology, used in earth-moving drilling, mining fluids, wellbore/well components, etc., can solve the problems of high cost, low work efficiency, complex fracturing ball process, etc. Solve the effect of high preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

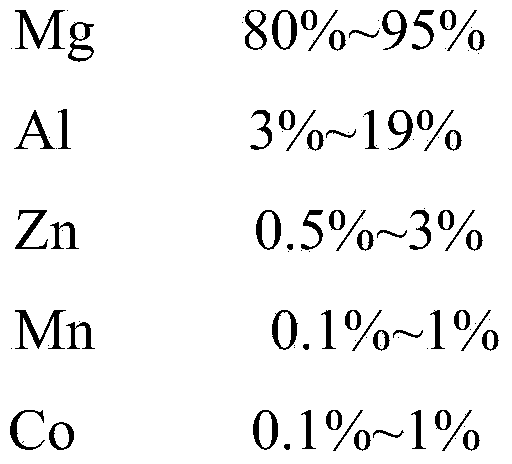

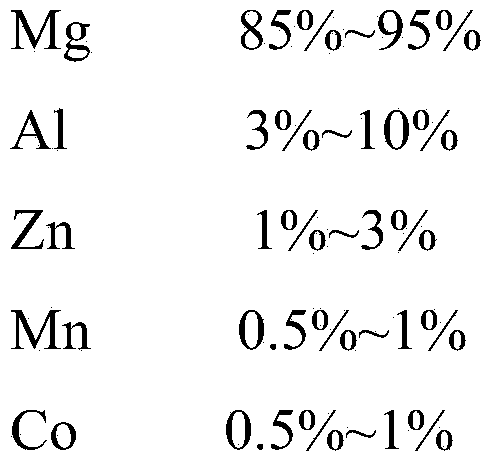

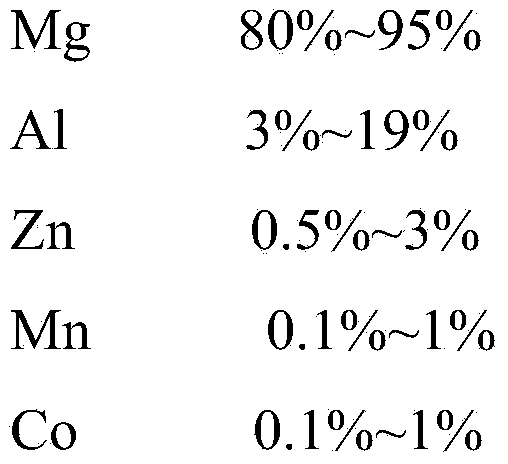

Method used

Image

Examples

Embodiment 1

[0031] ①Prepare 5 kinds of metal powders with a purity ≥99.9%, the mass parts are: Mg94%, Al3.5%, Zn1.5%, Mn0.7%, Co0.3%, and their particle sizes are: magnesium powder 50~ 60μm, aluminum powder 1~5μm, zinc powder 1~5μm, lead powder 1~5μm and cobalt powder 1~5μm

[0032] Place the above proportioned components in a vacuum powder mixer and mix evenly. During the mixing process, pass through argon protection, then put them into a cylindrical high-purity graphite mold, and pre-press with a pressure of 100 MPa on a cold press molding machine. forming;

[0033] ②Put the above pre-pressed materials in a vacuum sintering furnace for sintering. During the sintering process, argon protection is introduced, the sintering temperature is 550°C, the pressure is 170MPa during the sintering process, and the sintering time is 1.5h;

[0034]③ After the sintering is completed, the alloy is cooled with the furnace for 1 hour and then taken out to obtain a cylindrical alloy billet;

[0035] ④Th...

Embodiment 2

[0038] ①Prepare 5 kinds of metal powders with a purity ≥99.9%, the mass parts are: Mg89%, Al8.0%, Zn1.7%, Mn1.0%, Co0.3%, and their particle sizes are: magnesium powder 50~ 60 μm, aluminum powder 1-5 μm, zinc powder 1-5 μm, lead powder 1-5 μm and cobalt powder 1-5 μm. Place the above proportioned components in a vacuum powder mixer and mix them evenly. During the mixing process, pass through argon protection, then put them into a cylindrical high-purity graphite mold, and pre-press with a pressure of 100 MPa on a cold press molding machine. forming;

[0039] ②Put the above pre-pressed materials in a vacuum sintering furnace for sintering. During the sintering process, argon protection is introduced, the sintering temperature is 550°C, the pressure is 170MPa during the sintering process, and the sintering time is 1.5h;

[0040] ③ After the sintering is completed, the alloy is cooled with the furnace for 1 hour and then taken out to obtain a cylindrical alloy billet;

[0041] ...

Embodiment 3

[0044] ① Prepare 5 kinds of metal powders with a purity ≥ 99.9%, the mass parts are: Mg82%, Al15%, Zn1.7%, Mn1.0%, Co0.3%, and their particle sizes are: magnesium powder 50-70μm, Aluminum powder 1-5 μm, zinc powder 1-5 μm, lead powder 1-5 μm and cobalt powder 1-5 μm. Place the above proportioned components in a vacuum powder mixer and mix them evenly. During the mixing process, pass through argon protection, then put them into a cylindrical high-purity graphite mold, and pre-press with a pressure of 100 MPa on a cold press molding machine. forming;

[0045] ②Put the above pre-pressed materials in a vacuum sintering furnace for sintering. During the sintering process, argon protection is introduced, the sintering temperature is 550°C, the pressure is 170MPa during the sintering process, and the sintering time is 1.5h;

[0046] ③ After the sintering is completed, the alloy is cooled with the furnace for 1 hour and then taken out to obtain a cylindrical alloy billet;

[0047] ④...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com