How to finish calfskin style leather

A calfskin and leather technology, applied in the field of tanning, can solve the problems of increased production cost of calfskin leather goods, high price of calfskin leather blanks, limited quantity of calfskin leather blanks, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Embodiment 1 A kind of finishing method of imitation calfskin style leather

[0103] This method can make large-format yellow cowhide into calfskin-style leather, which is carried out in the following steps:

[0104] ⑴One time embossing

[0105] Adjust the ironing board of the leather embossing machine to a thin board pattern, the temperature is 80°C, the pressure is 150kgf, and the leather blank after retanning and dyeing of the large-format yellow cattle is embossed for 4 seconds. The embossed leather blank is A1, which is the same as The side that touches the ironing board is the front side;

[0106] ⑵ Polishing

[0107] Adjust the speed of the polishing machine to 90 yards / h, the gap between the felt and the roller to 2mm, and polish the front side of A1 to obtain B1;

[0108] ⑶ spray dye water

[0109] In parts by weight, 15 parts of dye water and 85 parts of water are evenly mixed, and the mixed dye water is evenly sprayed on the front of B1 with a manual spr...

Embodiment 2-6

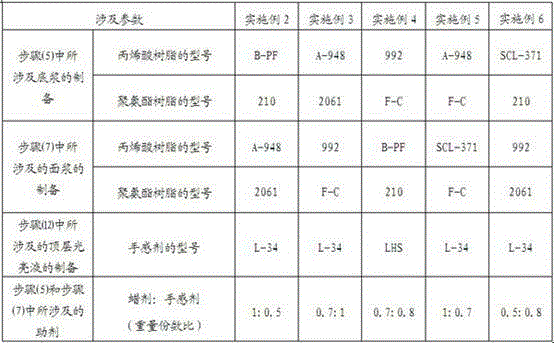

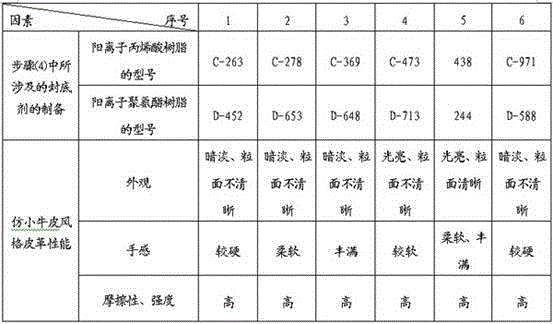

[0167] Embodiment 2-6 The finishing method of imitation calfskin style leather

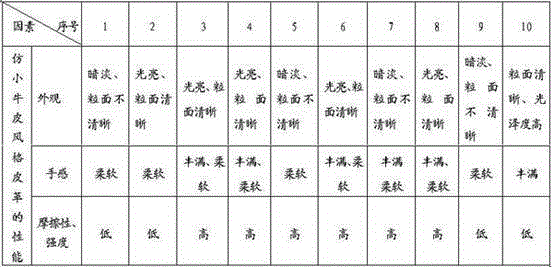

[0168] Embodiments 2-6 are respectively a method of finishing a calfskin-style leather, and the finishing process steps are the same as in Example 1, except that the parameters used in the finishing process are different, as shown in Table 1:

[0169] Table 1 Relevant parameters involved in the finishing method of imitation calfskin style leather

[0170]

[0171] The imitation calfskin style leather provided in Examples 2-6 has bright and transparent appearance, dark color, fine grain surface, clear pores, soft and smooth hand feeling, plump bones, wear-resistant coating and high strength; the finishing process is simple, Low production cost.

Embodiment 7

[0172] Example 7 Test of strength and color fastness to rubbing of imitation calfskin style leather

[0173] Embodiment 7 has carried out strength and color rubbing fastness test to imitation calfskin style leather provided in embodiment 1-6, and specific result is as follows:

[0174] ⑴Strength test

[0175] Tear strength≥60N / mm 2 , load elongation (when the tensile strength is 10N / mm 2 time) ≥ 50%;

[0176] ⑵Color fastness to rubbing test

[0177] Dry rubbing ≥ 4 (level), wet rubbing ≥ 3 (level).

[0178] Evaluation standard for domestic calfskin leather: when the tear strength is ≥50N / mm 2 , load elongation ≥ 45%, the strength of calfskin leather is qualified; when dry rubbing ≥ 3 (grade), wet rubbing ≥ 2 (grade), the color fastness to calfskin leather is qualified. When the tear strength ≥ 60N / mm 2 , When the load elongation rate is ≥50%, the strength of the calfskin leather is high; when the dry rubbing is ≥4 (grade), and the wet rubbing is ≥3 (grade), the color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com