Epoxy rust coating

An epoxy tape and coating technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of high use price and high price of chelated epoxy resin, and achieve improved adhesion, low cost, excellent The effect of coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

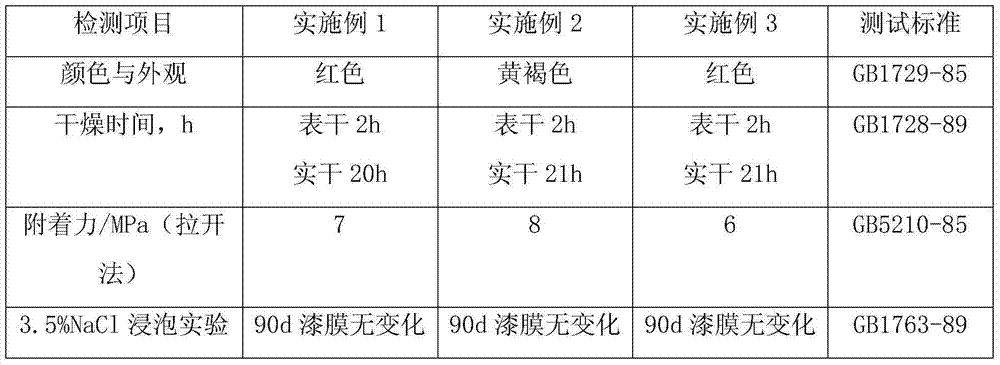

Examples

Embodiment 1

[0018] Preparation of component A: 10kg E44 epoxy resin, 10kg xylene, 4kg n-butanol, 5kg ethanol, 2kg phytic acid, 30kg aluminum tripolyphosphate, 30kg iron red, 0.01kg defoamer, 0.01kg leveling agent; Put it into a ball mill after mixing, disperse and pre-grind for 1.5 hours, and then take it out for use.

[0019] Before use, mix A component with 9kg Cardolite 2015 curing agent to obtain rust-coated epoxy resin paint.

Embodiment 2

[0021] Preparation of component A: 30kg E44 epoxy resin, 15kg xylene, 6kg n-butanol, 8kg ethanol, 4kg phytic acid, 20kg aluminum tripolyphosphate, 10kg zinc oxide, 0.01kg defoamer, 0.01kg leveling agent; After mixing, put it into a ball mill, disperse and ball mill it for 1.5 hours, and then take it out for use.

[0022] Before use, mix component A with 21kg of Cardolite 2015 curing agent to obtain an epoxy resin coating with rust coating. It can be coated on the steel surface whose surface derusting level is lower than Sa2.5.

Embodiment 3

[0024] Preparation of component A: 40kg E44 epoxy resin, 20kg xylene, 8kg n-butanol, 10kg ethanol, 4kg phytic acid, 30kg aluminum tripolyphosphate, 20kg zinc oxide, 10kg iron red, 0.02kg defoamer, 0.015kg flow Leveling agent; mix it and put it into a ball mill, disperse and ball mill it for 1.5 hours and take it out for later use.

[0025] Before use, mix component A with 28kg Cardolite 2015 curing agent to obtain epoxy resin paint with rust coating. It can be coated on the steel surface whose surface derusting level is lower than Sa2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com