Wall building material and preparation method thereof

A technology for building materials and walls, applied in the field of building materials, can solve the problems of building self-weight, low production efficiency, long infrastructure construction period, etc., and achieve the effects of reducing self-weight and cost, light bulk density, and improving earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

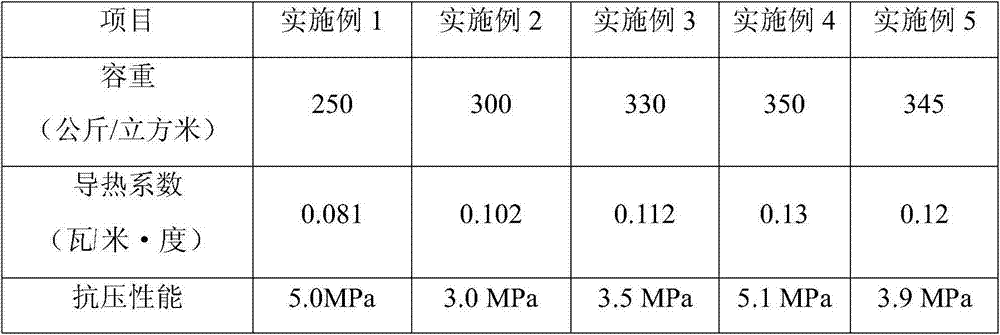

Examples

Embodiment 1

[0017] (1) Mix the following components in parts by weight evenly: 60 parts of ceramic polishing slag, 5 parts of feldspar, 10 parts of dickite, 2 parts of calcined talc, 15 parts of red mud, 10 parts of lithium feldspar, 0.5 parts of silicon carbide part and 1.5 parts of stabilizer, then add 50 parts of water, and carry out wet ball milling;

[0018] (2) Drying: after the ball-milled components are passed through a 200-mesh sieve, enter the spray drying tower for drying;

[0019] (3) Cellaring: Pour the dried powder into the cellar car in step (2) and scrape it off;

[0020] (4) Firing: firing at 1150°C for 19 hours in a continuous tunnel kiln;

[0021] (5) Cutting processing: The fired products are cut and processed into ceramic foam insulation wall bricks or boards of the following sizes: 600mm×600mm×15mm, 600mm×600mm×22mm, 600mm×1200mm×15mm and 600mm× 1200mm×22mm.

Embodiment 2

[0023] (1) Mix the following components uniformly in parts by weight: 50 parts of ceramic polishing slag, 20 parts of red mud, 10 parts of feldspar, 10 parts of lithium feldspar, 8 parts of calcined talc, 0.5 part of silicon carbide, 1.5 parts of zirconium carbonate part, then add 45 parts of water, and carry out wet ball milling;

[0024] (2) Drying: after the ball-milled components are passed through a 200-mesh sieve, enter the spray drying tower for drying;

[0025] (3) Cellaring: Pour the dried powder into the cellar car in step (2) and scrape it off;

[0026] (4) Firing: Firing in a continuous tunnel kiln, the firing temperature is 1150°C, and the firing time is 18 hours;

[0027] (5) Cutting processing: The fired products are cut and processed into ceramic foam insulation wall bricks or boards of the following sizes: 600mm×600mm×15mm, 600mm×600mm×22mm, 600mm×1200mm×15mm and 600mm× 1200mm×22mm.

Embodiment 3

[0029] (1) Mix the following components uniformly in parts by weight: 65 parts of ceramic polishing slag, 10 parts of red mud, 5 parts of dikai stone, 10 parts of lithium feldspar, 6 parts of calcined talc, 2 parts of silicon carbide, barium carbonate 2 parts, then add 50 parts of water to carry out wet ball milling;

[0030] (2) Drying: after the ball-milled components are passed through a 250-mesh sieve, enter the spray drying tower for drying;

[0031] (3) Cellaring: Pour the dried powder into the cellar car in step (2) and scrape it off;

[0032] (4) Firing: firing at 1180°C for 19 hours in a continuous tunnel kiln;

[0033] (5) Cutting processing: The fired products are cut and processed into ceramic foam insulation wall bricks or boards of the following sizes: 600mm×600mm×15mm, 600mm×600mm×22mm, 600mm×1200mm×15mm and 600mm× 1200mm×22mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com