Simple exhaust pipe cabin-communicated part

A technology for exhaust pipes and cabin openings, which is applied in the field of simple exhaust pipe openings, can solve the problems of not meeting the design requirements of ships, affecting the separation and sealing of cabins, and weakening the strength of bulkheads. The effect of ensuring ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

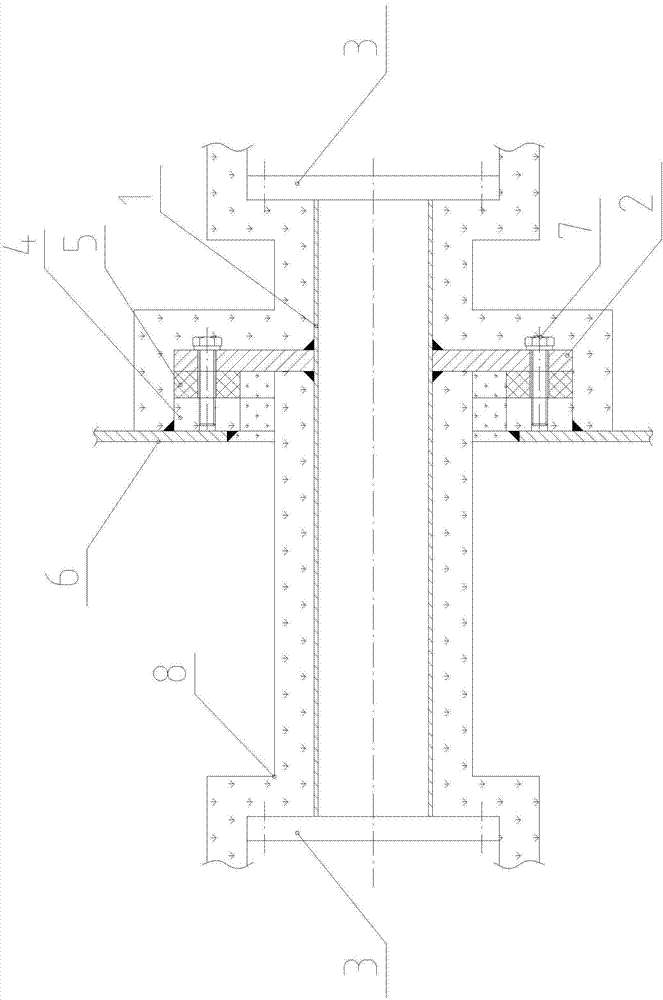

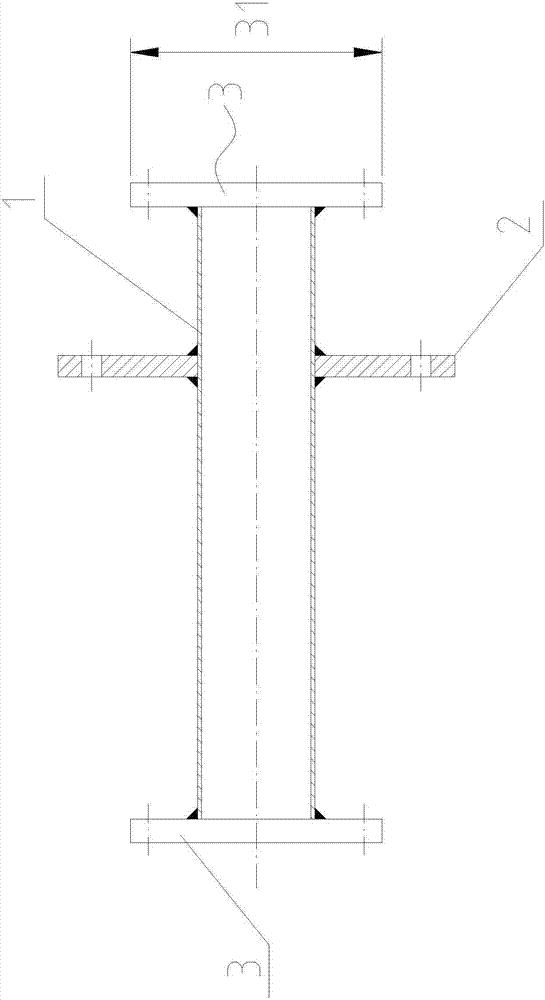

[0025] Such as Figure 1 to Figure 5 As shown, a simple exhaust pipe opening is opened on the bulkhead 6 that needs to pass through the exhaust pipe 1. There is a first through hole 61 for the exhaust pipe to pass through, including a single-sided seat plate 4, a gasket piece 5 and intermediate flange 2;

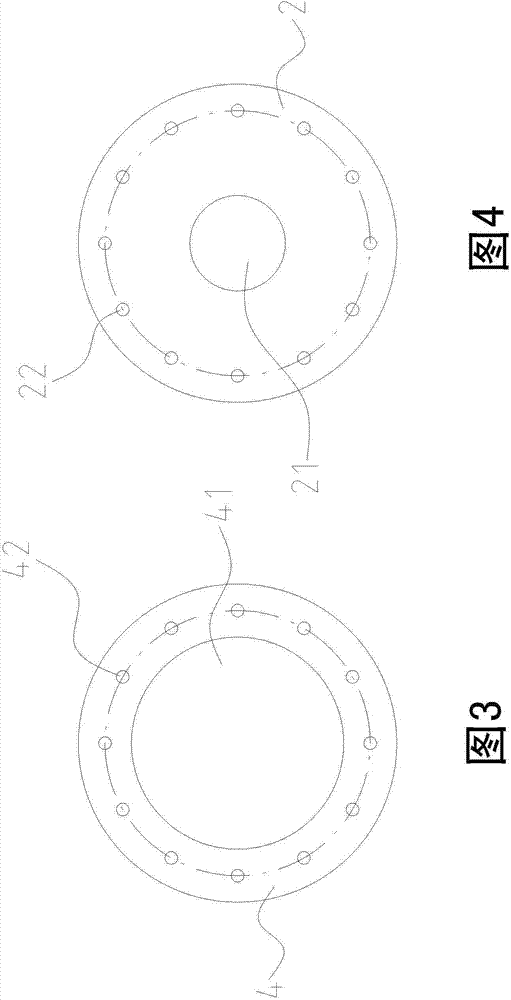

[0026] The single-sided seat plate 4 is provided with a second through hole 41 for the exhaust pipe 1 to pass through and several screw holes 42 distributed circumferentially around the second through hole 41. The single-sided seat plate 4 is welded on the bulkhead 6 and The first through hole 61 communicates with the second through hole 41;

[0027] The middle flange 2 is provided with a third through hole 21 through which the exhaust pipe 1 passes and several holes 22 distributed circumferentially around the third through hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com