CNC (computer numerical control) rotating workpiece fixing and clamping device used for horizontal milling machine

A technology for rotating workpieces and holding devices, applied in automatic control devices, general control systems, program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0044] The following descriptions are the best embodiments for realizing the present invention, however, these embodiments are not intended to limit the present invention, and their purpose is only to describe one or more preferred embodiments of the present invention. The scope of patent protection of the present invention is defined by the contents of the claims.

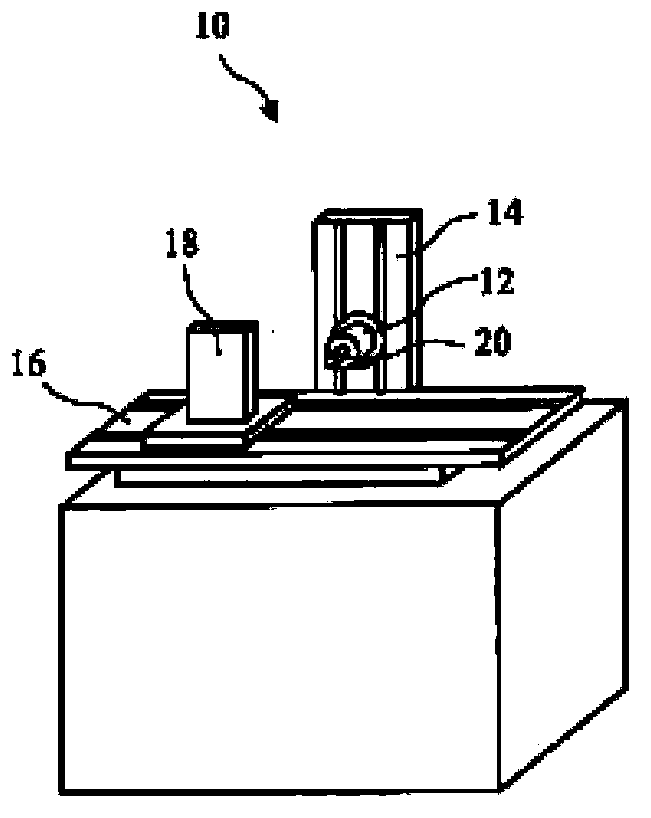

[0045] figure 1 A conventional horizontal milling machine 10 is shown. The horizontal milling machine 10 includes a vertical guide plate 14 equipped with a spindle 12 , and a horizontal table 16 equipped with a vertical base 18 . The vertical base 18 slides laterally along the table 16 to position a workpiece mounted on the vertical base 18 so that the workpiece can be cut by a milling cutter 20 driven by the spindle 12 .

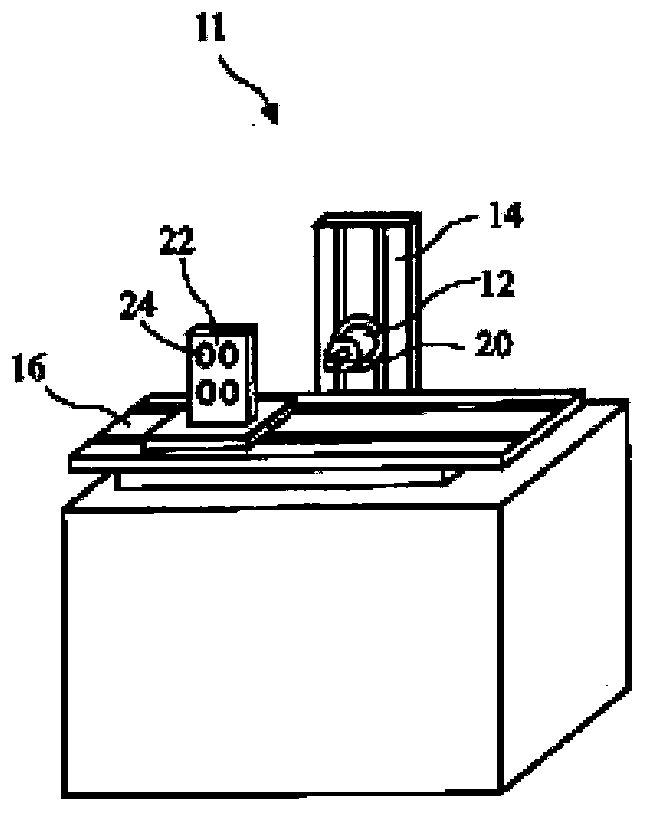

[0046] figure 2 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com