Sheet punching device and punching method thereof

A technology for thin plates to be processed, which is applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc. It can solve the problems of inability to adjust the processing size and low processing accuracy according to needs, and achieve shortened processing cycle and high precision. High, avoid deformation or fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

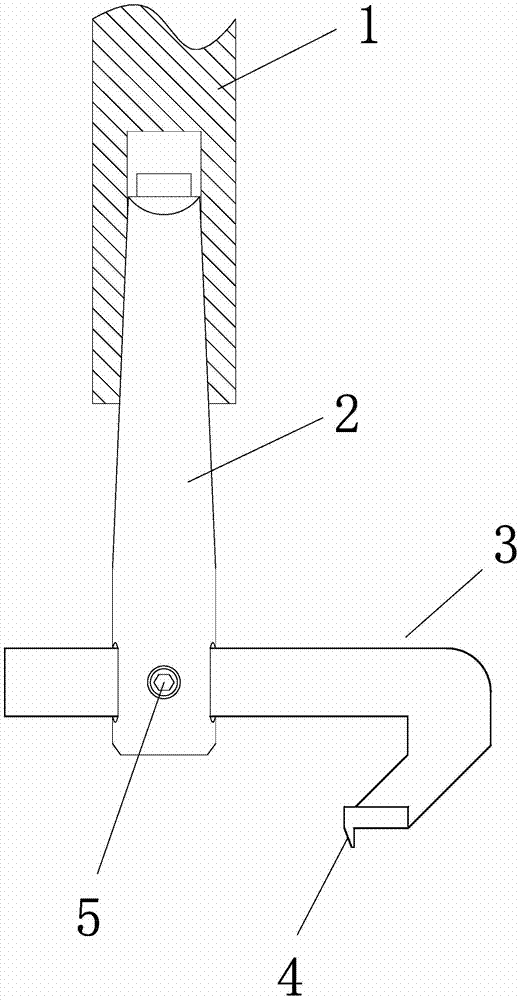

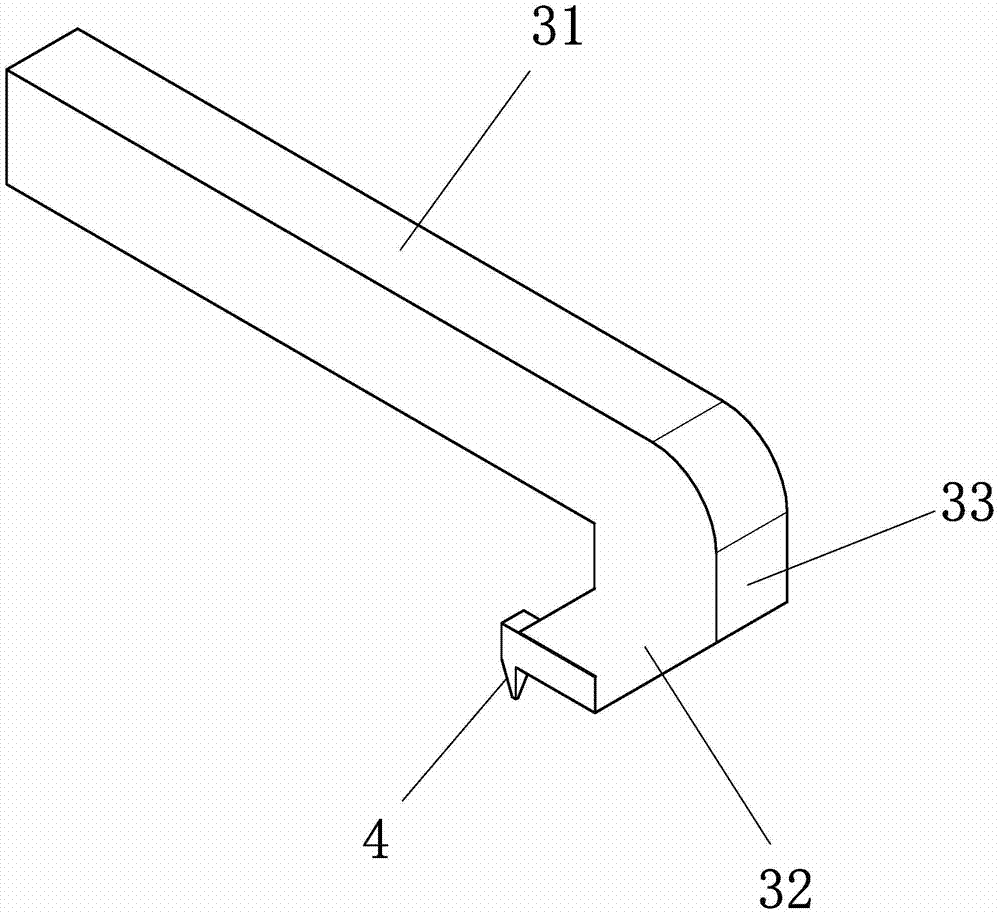

[0027] Embodiment 1: as figure 1 , 2 As shown, a thin plate hole opening device includes a tool bar 2 connected to a drill press. The tool bar 2 is inserted into a rotating sleeve 1 of the drilling machine. The rotation of the rotating sleeve 1 of the drilling machine can drive the tool bar 2 to rotate. A knife holder bar 3 runs through the lower end of the knife bar 2 , and the knife holder bar 3 includes a connecting arm 31 and a fixed arm 32 , and the lower end of the fixed arm 32 is fixed with a blade 4 . The fixed arm 32 is connected to the connecting arm 31 through the transition arm 33, the angle between the transition arm 33 and the connecting arm 31 is a right angle, and the angle between the transition arm 33 and the fixed arm 32 is an obtuse angle, that is, the space angle between the fixed arm 32 and the connecting arm 31 is an acute angle. The connecting arm 31 radially penetrates the lower end of the tool bar 2 and is fixed by the locking post 5. The locking po...

Embodiment 2

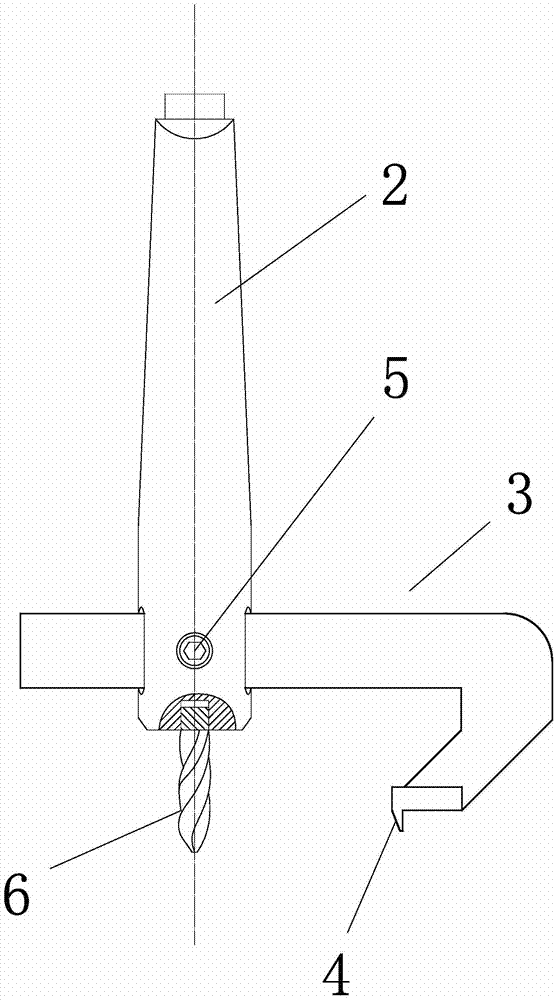

[0030] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as image 3 As shown, the lower end surface of the cutter bar 2 is plugged with a positioning drill bit 6 , and the positioning drill bit 6 is coaxial with the cutter bar 2 . The vertical distance from the lowermost end of the positioning drill bit 6 to the lower end surface of the cutter bar is greater than or equal to the vertical distance from the lowermost end of the blade 4 to the lower end surface of the cutter bar. The difference between the vertical distance from the lowermost end of the positioning drill 6 to the lower end surface of the cutter bar and the vertical distance from the lowermost end of the blade 4 to the lower end surface of the cutter bar is smaller than the thickness of the thin plate 10 to be processed.

[0031] The lower end surface of the cutter bar is provided with a positioning drill bit, and the extension length of the posi...

Embodiment 3

[0033] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1 or 2, the difference is that, as Figure 6 , 7 As shown, there is a drip hole 312 on the lower end surface of the connecting arm 31. The drip hole 312 is vertically corresponding to the blade 4. There is a perforation 311 at the axis of the connecting arm 31. The perforation 311 communicates with the drip hole 312. The perforation 311 runs through an infusion soft tube. Pipe 7, one end of the infusion hose 7 extends to the drip hole 312, and the other end is connected with the water source 9, the water source 9 is a water bag, the water source 9 surrounds the outer surface of the rotating shaft sleeve 1 fixed on the drilling machine, and the infusion hose 7 is equipped with Water volume control valve 8 that controls water flow by squeezing the infusion hose.

[0034] During the cutting process of the blade, open the water control valve, so that the cooling water of the water so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com